Steel surface coating and preparation method thereof

A surface coating and coating technology, applied in coatings, protein coatings, anti-corrosion coatings, etc., to achieve good bonding performance and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First weigh 9.15g boric acid (H 3 BO 3 ) and 14.20g borax (Na 2 B 4 o 7 10H 2 O) Add 1000 mL of deionized water and place it on a magnetic stirrer to fully stir and dissolve, and prepare a boric acid-sodium borate buffer solution with a pH value of 8.40±0.05. Take 10mL of mussel mucin stock solution with a concentration of 5.0mg / mL and add it to 50mL of prepared boric acid-sodium borate buffer solution with a pH value of 8.40±0.05, stir the solution fully after adding, the preparation of the deposition solution is completed, and the pH of the prepared deposition solution is The value is 8.20.

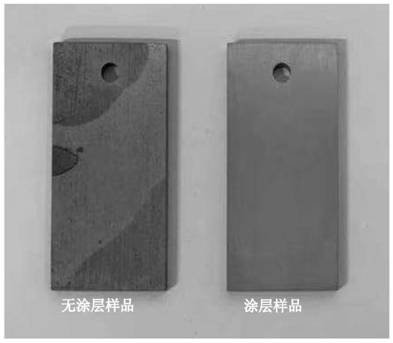

[0027] The sheet-shaped Q235 steel sample was degreased with acetone, ultrasonically cleaned with absolute ethanol for 1 min, then fully rinsed with deionized water, dried with cold air and immersed in a deposition solution with a water bath temperature control temperature of 25°C for 16 h of deposition.

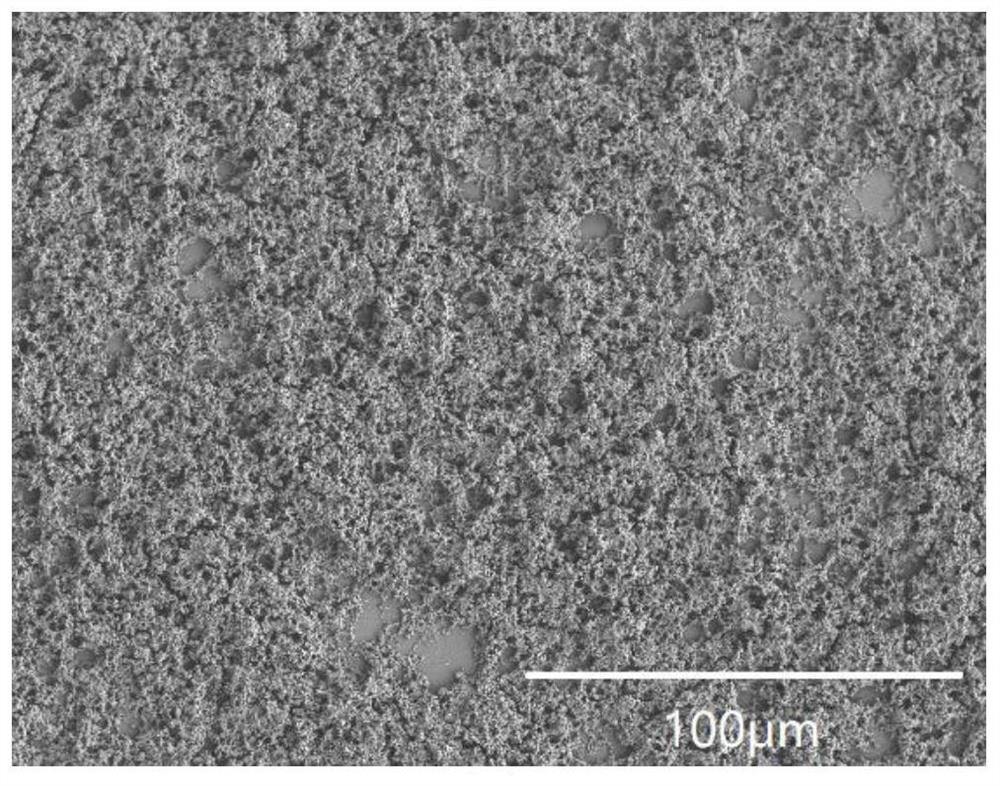

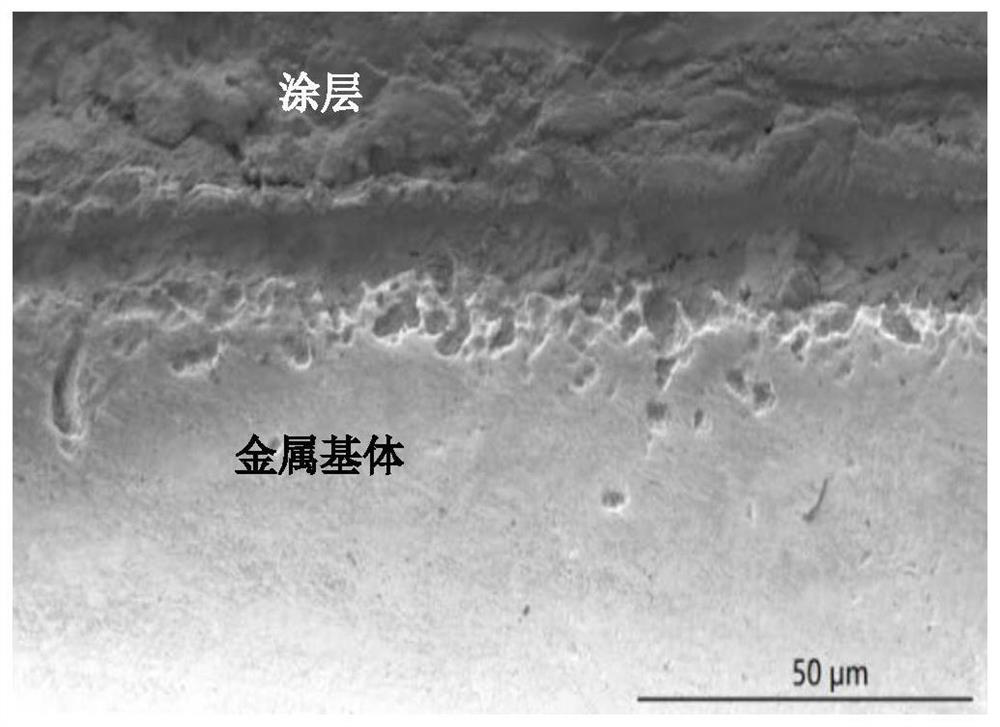

[0028] After the deposition was completed, the steel sample was drie...

Embodiment 2

[0033] First weigh 9.15g boric acid (H 3 BO 3 ) and 14.20g borax (Na 2 B 4 o 7 10H 2 O) Add 1000 mL of deionized water and place it on a magnetic stirrer to fully stir and dissolve, and prepare a boric acid-sodium borate buffer solution with a pH value of 8.40±0.05. Take 10ml of mussel mucin stock solution with a concentration of 5.0mg / mL and add it to 70mL of boric acid-sodium borate buffer solution with a pH value of 8.40±0.05. After adding, stir the solution fully. The preparation of the deposition solution is completed, and the pH of the prepared deposition solution is The value is 8.30.

[0034] The sheet-shaped Q235 steel sample was degreased with acetone, ultrasonically cleaned with absolute ethanol for 1 min, then fully rinsed with deionized water, dried with cold air and immersed in a deposition solution with a water bath temperature control temperature of 25°C for 20 h of deposition.

[0035] After the deposition was completed, the steel sample was dried in an ...

Embodiment 3

[0038] First weigh 9.15g boric acid (H 3 BO 3 ) and 14.20g borax (Na 2 B 4 o 7 10H 2 O) Add 1000 mL of deionized water and place it on a magnetic stirrer to fully stir and dissolve, and prepare a boric acid-sodium borate buffer solution with a pH value of 8.40±0.05. Take 10mL of mussel mucin stock solution with a concentration of 5.0mg / mL and add it to the boric acid-sodium borate buffer solution with a pH value of 8.40±0.05 prepared by 90mL, stir the solution fully after adding, and the preparation of the deposition solution is completed. The value is 8.30.

[0039] The sheet-shaped Q235 steel sample was degreased with acetone, ultrasonically cleaned with absolute ethanol for 1 min, then fully rinsed with deionized water, dried with cold air and immersed in a deposition solution with a water bath temperature control temperature of 25°C for 24 h of deposition.

[0040] After the deposition is completed, the steel sample is dried in an oven at 40° C. for 2 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com