Method for producing PHA (polyhydroxyalkanoate) by using pseudomonas corrugata type II synthase

A technology of Pseudomonas and unicellular, which is applied in the field of producing PHA by using Pseudomonas wrinkle type II synthase, and can solve the problems of low production volume and high production cost of PHA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

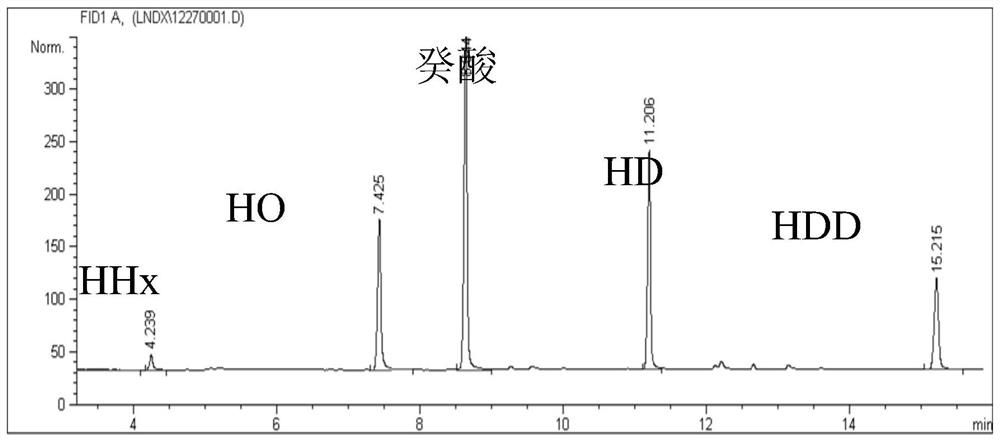

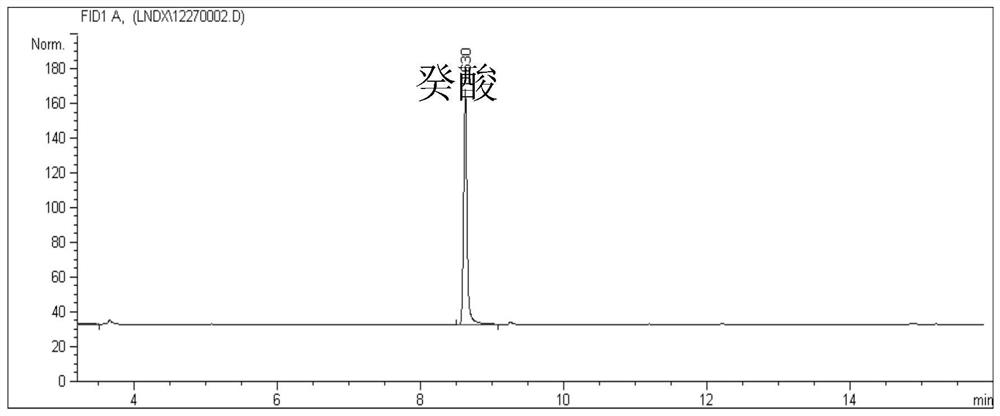

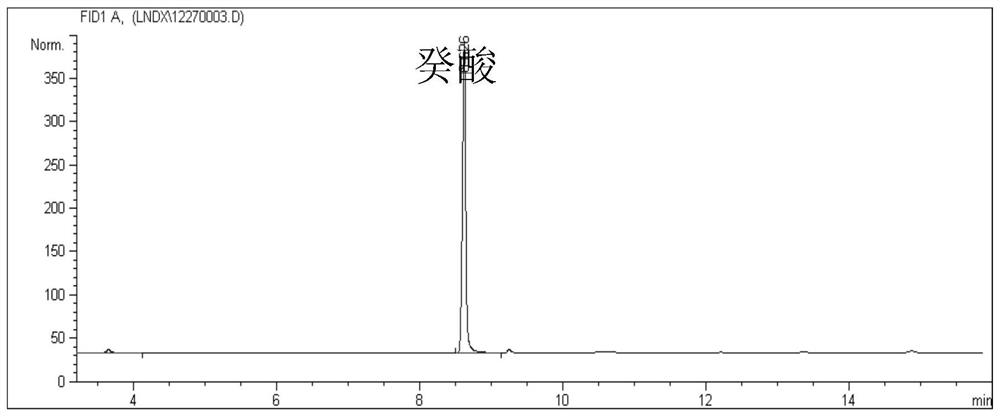

Examples

Embodiment 1

[0030] Embodiment 1 uses Pseudomonas rugosa type II synthase to produce PHA with sodium oleate as carbon source

[0031] Strain: Pseudomonas rugosa pBBR1MCS2-phaC2

[0032] Medium:

[0033] 1. LB medium: 5g / l yeast extract, 10g / l tryptone, 10g / l NaCl, sterilized at 121°C for 15-20min after aliquoting.

[0034] 2. LB agar medium (pH 7.0-7.2): After adding the above ingredients, add 15g / l agar powder, subpackage and extinguish at 121°C for 15-20min.

[0035] 3. Mineral salt fermentation medium:

[0036] Table 1 Mineral salt fermentation medium component table

[0037]

[0038] Culture method: Culture Pseudomonas rugosa on LB agar medium at 30°C for about 12 hours, pick a single colony and inoculate it in 10ml of LB medium, shake at 30°C, 200rpm, 8-12h, as seed solution. Then add 1% sodium oleate to component II to prepare a mineral salt fermentation medium as a carbon source, inoculate the recombinant bacteria of pBBR1MCS2-phaC2 (preserved from our laboratory) with a 5% i...

Embodiment 2

[0062] Example 2 proves that Pseudomonas rugosa type II synthase produces PHA with sodium oleate as carbon source

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com