A preliminary screening method and device for silicon carbide crystal ingots

A technology for preliminary screening and silicon carbide, applied in chemical instruments and methods, fine working devices, crystal growth, etc., can solve the problems of high work intensity, low visibility of silicon carbide ingots, and difficulty in human judgment. Work intensity, improve visibility, provide work efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

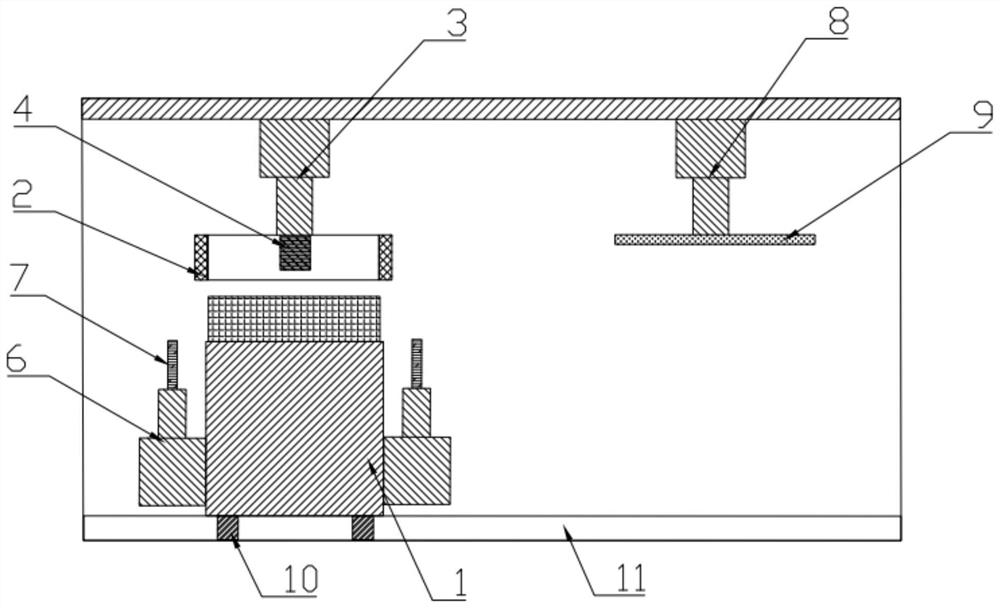

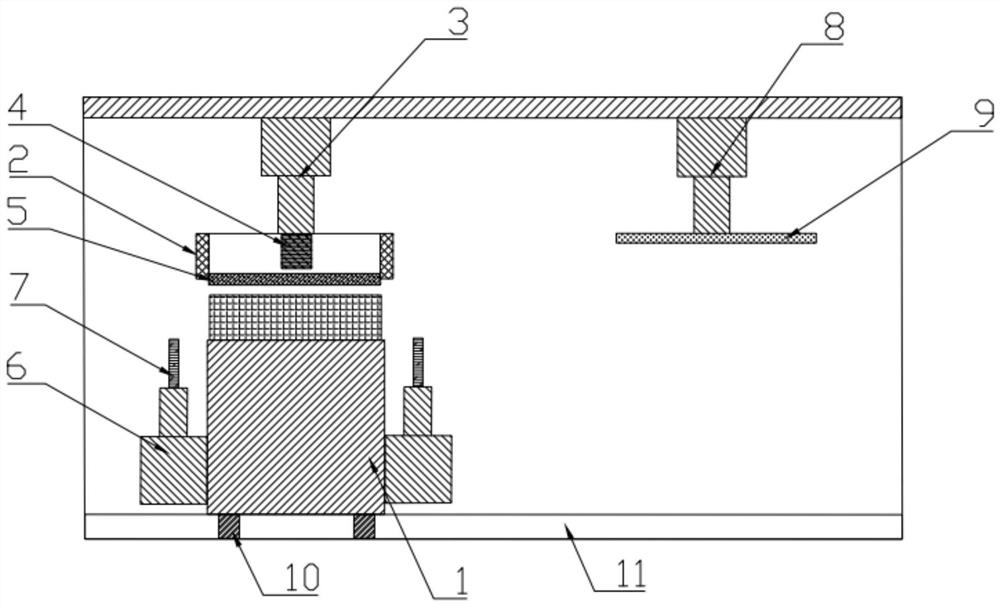

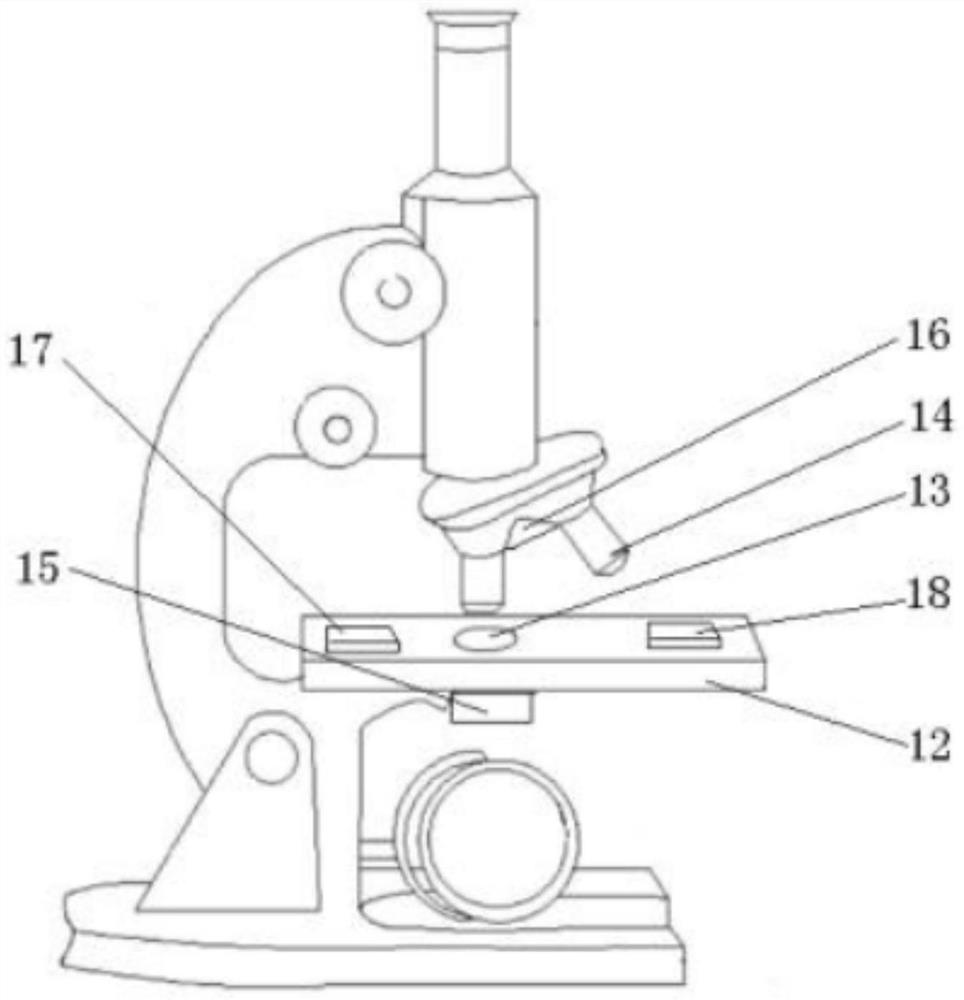

[0049] refer to figure 1 , the present embodiment provides a preliminary screening device for silicon carbide ingots, the device includes a grinding processing unit and a detection unit, the grinding processing unit includes a placement platform 1, a grinding shaft 2 and a cutting structure 9, the placement platform 1 is used For placing the silicon carbide crystal ingot, the grinding shaft 2 is arranged above the placement platform 1, the grinding shaft 2 can rotate, the inner wall of the grinding shaft 2 is provided with a grinding surface, and the grinding surface can be in contact with the side of the silicon carbide crystal ingot, so that the silicon carbide crystal The sides of the ingot are ground. The grinding surface of the grinding shaft is used for grinding the side of the silicon carbide ingot; the bottom end of the grinding shaft 2 is detachably mounted with a grinding plate 5, and the grinding plate 5 is used for grinding the seed crystal surface of the silicon c...

Embodiment 2

[0064] This embodiment provides a method for preliminary screening of silicon carbide crystal ingots, the method comprising the following steps:

[0065] 1. Grinding the side of the silicon carbide ingot, and removing the seed crystal surface and convex surface of the silicon carbide ingot: place the silicon carbide ingot on the placement platform, and after fixing the silicon carbide ingot, control the movement of the grinding shaft , so that the silicon carbide crystal ingot is located inside the grinding shaft; the rotation of the grinding shaft is controlled so that the grinding shaft grinds the side of the silicon carbide crystal ingot; The plate contacts the seed crystal surface of the silicon carbide ingot; the rotation of the grinding shaft is controlled so that the grinding plate polishes and removes the seed crystal surface; the convex surface of the silicon carbide ingot is fixed upward, and the side of the silicon carbide ingot is fixed to control the movement of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com