Cooling device for metallurgical furnace charge production

A technology of cooling device and charge, applied in the direction of water shower cooler, direct contact heat exchanger, heat exchanger type, etc., can solve the problems of reduced service life of the device, easy entry of debris and dust, etc., to avoid unrecoverable deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

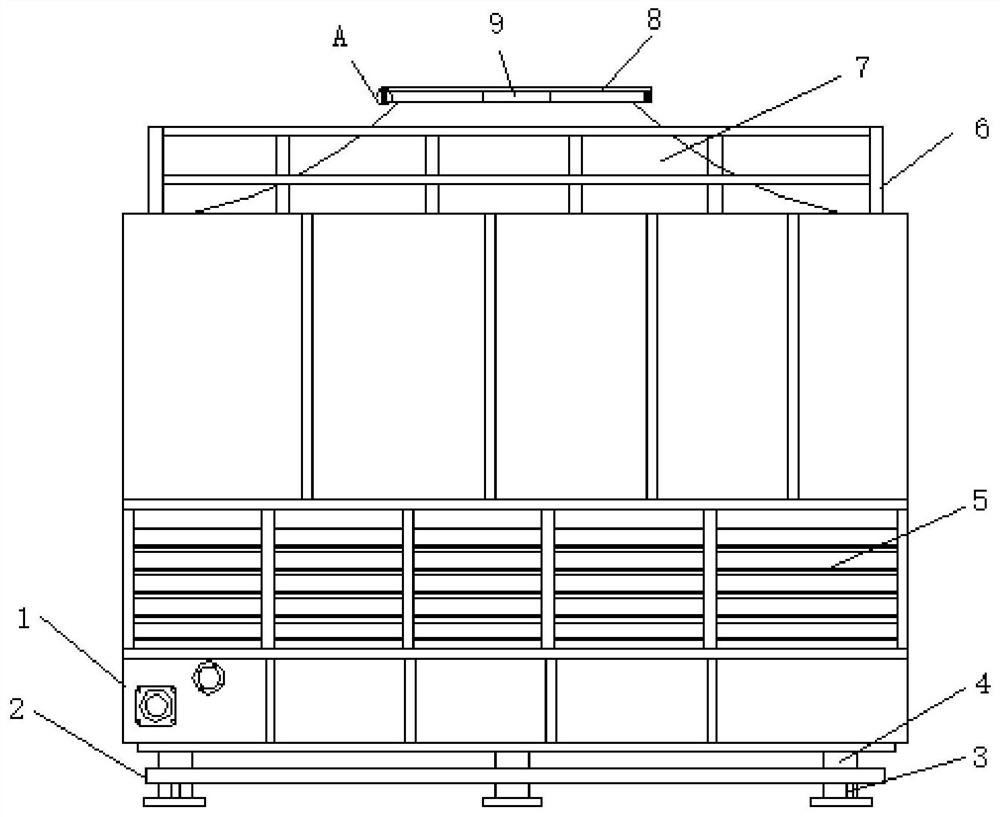

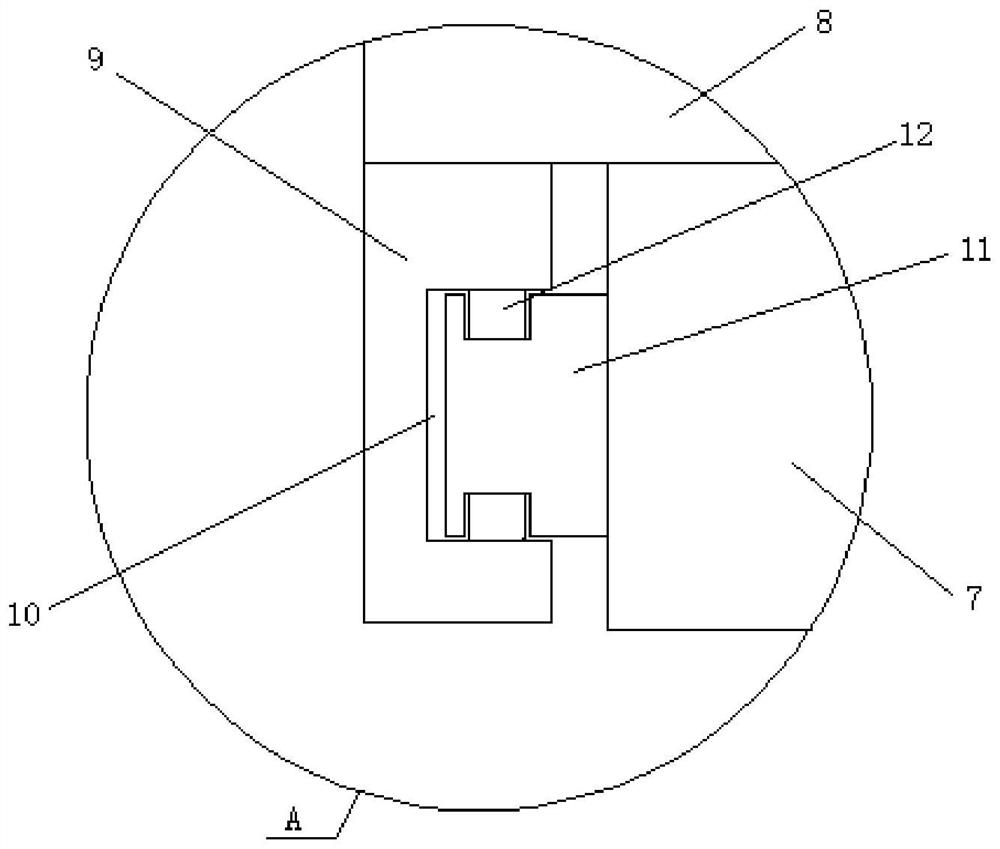

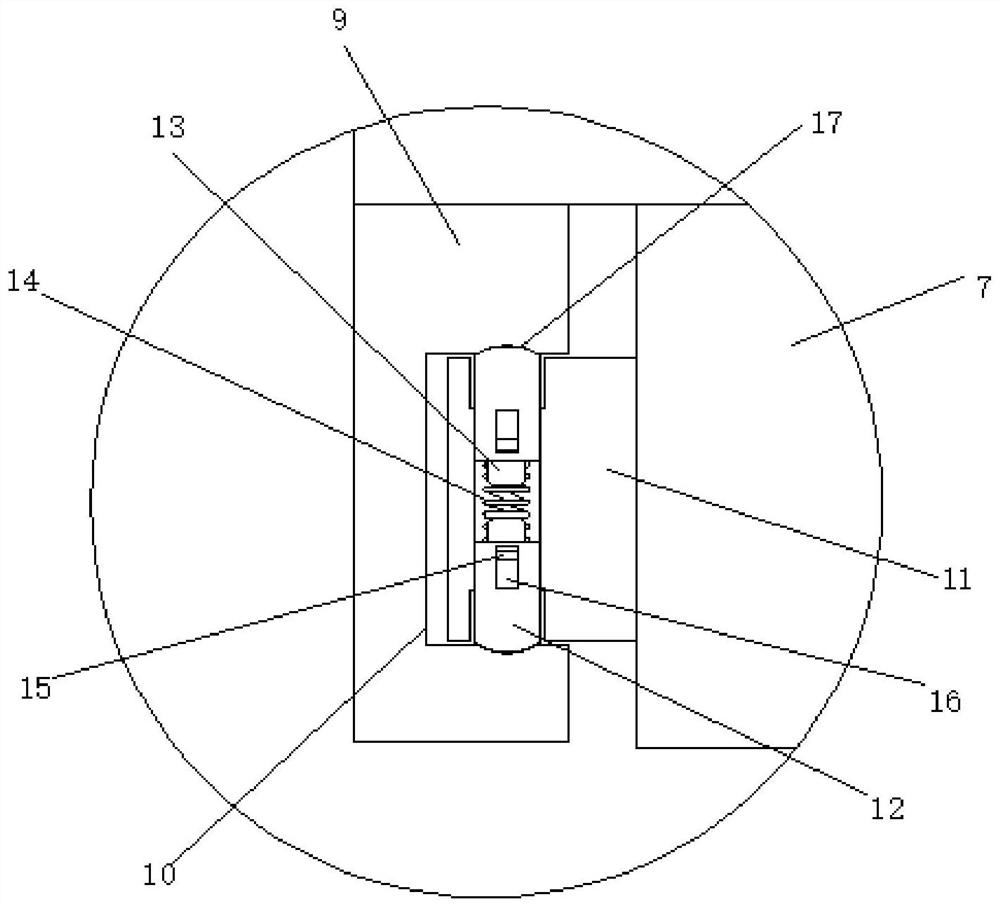

[0024] see Figure 1 to Figure 5 , the present invention provides a technical solution: a cooling device for the production of metallurgical charge, comprising a tower body 1, an exhaust port 7 is arranged on the top of the tower body 1, an upper frame 8 is arranged on the top of the exhaust port 7, and the inner side of the upper frame 8 is fixed There is a stainless steel mesh plate 18, the designed stainless steel mesh plate 18, the stainless steel mesh plate 18 is placed on the top of the exhaust port 7, and then plays the role of isolating impurities, preventing impurities from entering the device and causing damage to the device, the top frame 8 The four quadrants of the bottom are fixed with side plates 9, and the sides of the side plates 9 are provided with installation grooves 10, and the four quadrants of the side walls of the exhaust port 7 are fixed with installation plates 11, and one end of the installation plate 11 is placed in the installation groove 10 Inside,...

Embodiment 2

[0026] see Figure 1 to Figure 6 , the present invention provides a technical solution: a cooling device for the production of metallurgical charge, comprising a tower body 1, an exhaust port 7 is arranged on the top of the tower body 1, an upper frame 8 is arranged on the top of the exhaust port 7, and the inner side of the upper frame 8 is fixed There is a stainless steel mesh plate 18, the designed stainless steel mesh plate 18, the stainless steel mesh plate 18 is placed on the top of the exhaust port 7, and then plays the role of isolating impurities, preventing impurities from entering the device and causing damage to the device, the top frame 8 The four quadrants of the bottom are fixed with side plates 9, and the sides of the side plates 9 are provided with installation grooves 10, and the four quadrants of the side walls of the exhaust port 7 are fixed with installation plates 11, and one end of the installation plate 11 is placed in the installation groove 10 Inside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com