Photocatalyst formaldehyde-removing freshener and preparation method thereof

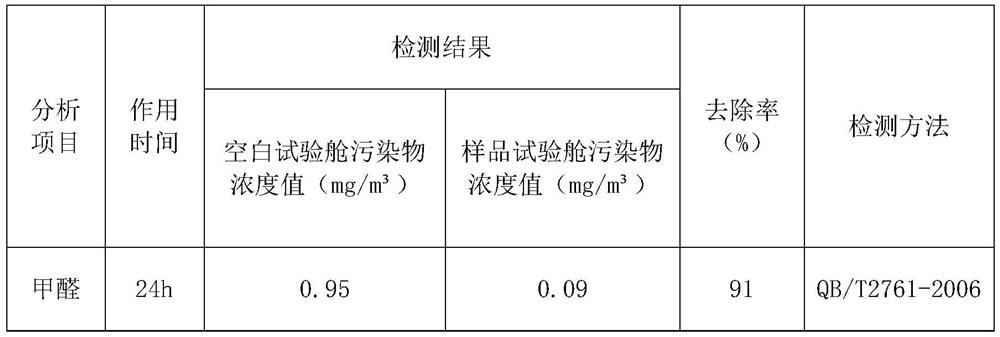

A technology of photocatalyst and freshener, applied in separation methods, chemical instruments and methods, deodorization, etc., can solve the problems of poor formaldehyde removal effect, high cost, and complex components, so as to improve catalytic efficiency, ensure quality, and strengthen decomposition effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention also provides a preparation method of a photocatalyst formaldehyde-removing freshener, which includes the following steps:

[0032] Titanium dioxide suspension preparation: use an electrolytic hydrogen-rich water machine to prepare hydrogen-rich water, then take part of the hydrogen-rich water, add titanium dioxide to it, stir and mix under ultrasonic to make a titanium dioxide suspension;

[0033] Preparation of platinic element mixture: take part of the alcohol and add platinic element powder to it, stir and mix, add the remaining alcohol, continue stirring and mixing to obtain platinic element mixed liquid;

[0034] Finished product preparation: add essence and mint powder to the remaining hydrogen-rich water, stir and mix, then add titanium dioxide suspension and platinum light element mixture, continue to stir under ultrasonic, and then pack to obtain the finished product.

[0035]In the above examples, firstly, the titanium ...

Embodiment 1

[0044] The present embodiment provides a photocatalyst formaldehyde-removing refreshing agent, which is prepared by the following method:

[0045] Preparation of titanium dioxide suspension: use an electrolytic hydrogen-rich water machine to prepare 30g of hydrogen-rich water with a hydrogen content of 1PPM, and then take part of the hydrogen-rich water, and add 0.08g of titanium dioxide with a particle size of 5nm to it, and use it at an ultrasonic frequency of 28KHz , stirring and mixing at a rate of 300rpm to make a titanium dioxide suspension;

[0046] Preparation of platinic element mixture: take a part of 25g of alcohol with a concentration of 30%, and add 0.08g of platinic element powder to it, stir and mix at a speed of 300rpm, then add the remaining alcohol, continue stirring and mixing to obtain a platinic element mixture liquid;

[0047] Finished product preparation: Add 0.5g of essence and 0.04g of mint powder to the remaining hydrogen-rich water, stir and mix, th...

Embodiment 2

[0049] The present embodiment provides a photocatalyst formaldehyde-removing refreshing agent, which is prepared by the following method:

[0050] Preparation of titanium dioxide suspension: Use an electrolytic hydrogen-rich water machine to prepare 70g of hydrogen-rich water with a hydrogen content of 1PPM, and then take part of the hydrogen-rich water, and add 0.6g of titanium dioxide with a particle size of 3nm to it, and use it at an ultrasonic frequency of 40KHz , stirring and mixing at a rate of 800rpm to make a titanium dioxide suspension;

[0051] Preparation of Platinum Mixture: Take a part of 30% alcohol 30-40g and add 0.6g of Platinum powder to it, stir and mix at 800rpm, add the remaining alcohol, continue to stir and mix to get Platinum Primer mixture;

[0052] Finished product preparation: Add 4g of essence and 0.2g of mint powder to the remaining hydrogen-rich water, stir and mix, then add the titanium dioxide suspension and platinum light element mixture, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com