Method for preparing cobalt phosphide/biochar composite material by taking yeast nucleic acid as phosphorus source and carbon source

A yeast nucleic acid and composite material technology, applied in chemical instruments and methods, chemical/physical processes, catalyst activation/preparation, etc., can solve the problems of high toxicity, high cost, etc., achieve good adsorption performance, wide application range, and efficient removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

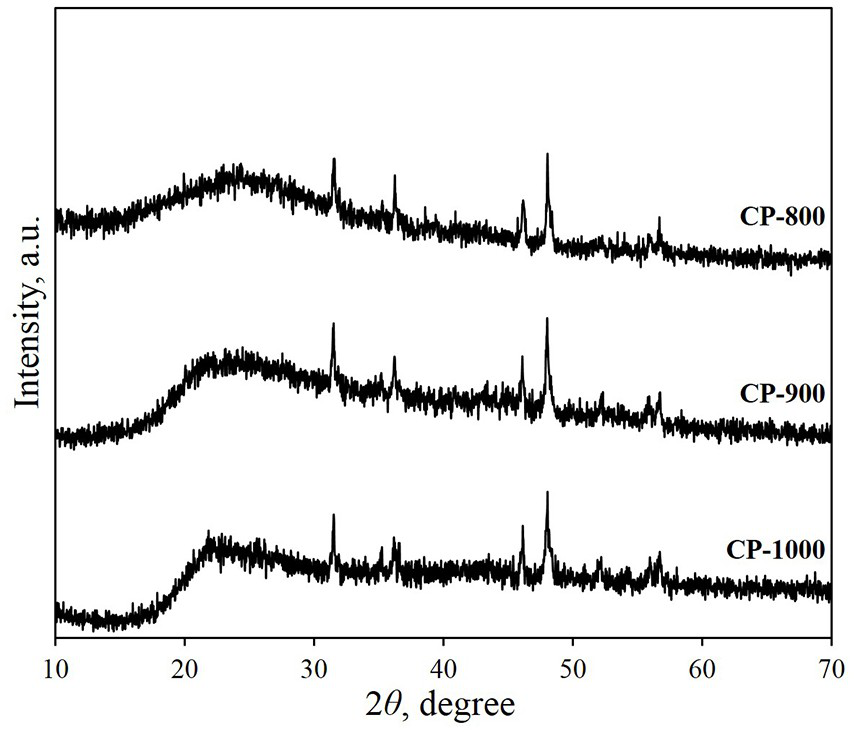

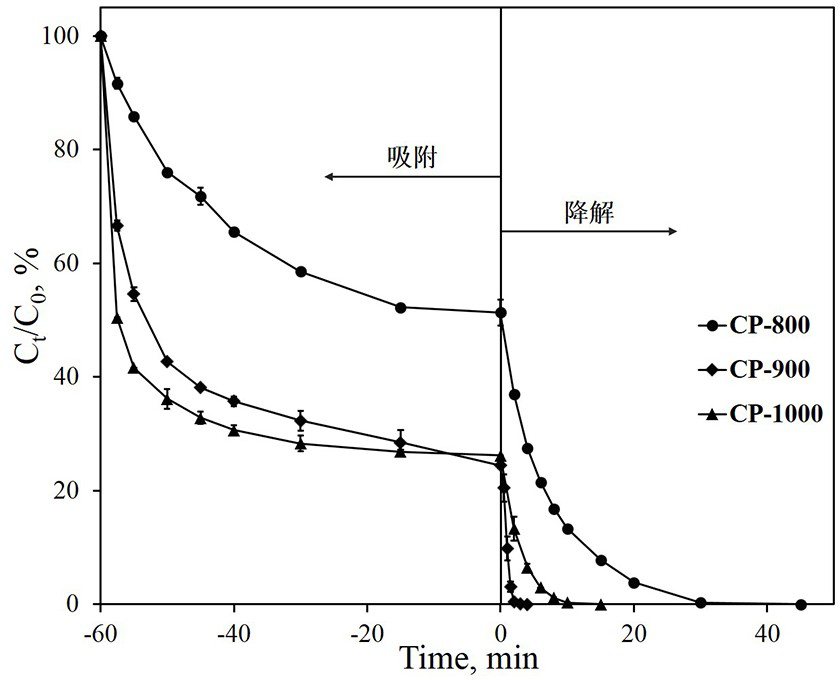

[0025] Evenly disperse the nucleic acid extracted from baker's yeast cells by concentrated salt method in 20-100 mL deionized water, slowly add 0.1-0.2 mol / L cobalt nitrate hexahydrate solution while stirring, and continue stirring for 5-12 h, The resulting complex was centrifuged, washed with water, and dried in a freeze dryer. Mix the dried complex with 1-10 times the mass of sodium chloride and potassium chloride, grind it into powder, transfer it to a corundum crucible, and place it in a tube furnace for calcination under a protective atmosphere at a calcination temperature of 800°C , 900 ℃, 1000 ℃, the calcination time is 3-6 h, the heating rate is 5 ℃ / min, take it out after cooling to room temperature, and obtain the material containing sodium chloride and potassium chloride. The obtained material was dispersed in deionized water and ultrasonically filtered and washed to remove sodium chloride and potassium chloride, dried in an oven at 60 °C, and ground into a fine powd...

Embodiment 2

[0027] Evenly disperse the nucleic acid extracted from baker's yeast cells by concentrated salt method in 20-100 mL deionized water, slowly add 0.1-0.2 mol / L cobalt nitrate hexahydrate solution while stirring, and continue stirring for 5-12 h, The resulting complex was centrifuged, washed with water, and dried in a freeze dryer. Mix the dried complex with 1-10 times the mass of sodium chloride and potassium chloride, grind it into powder, transfer it to a corundum crucible, and place it in a tube furnace for calcination under a protective atmosphere at a calcination temperature of 800°C , 900 ℃, 1000 ℃, the calcination time is 3-6 h, the heating rate is 5 ℃ / min, take it out after cooling to room temperature, and obtain the material containing sodium chloride and potassium chloride. The obtained material was dispersed in deionized water and ultrasonically filtered and washed to remove sodium chloride and potassium chloride, dried in an oven at 60 °C, and ground into a fine powd...

Embodiment 3

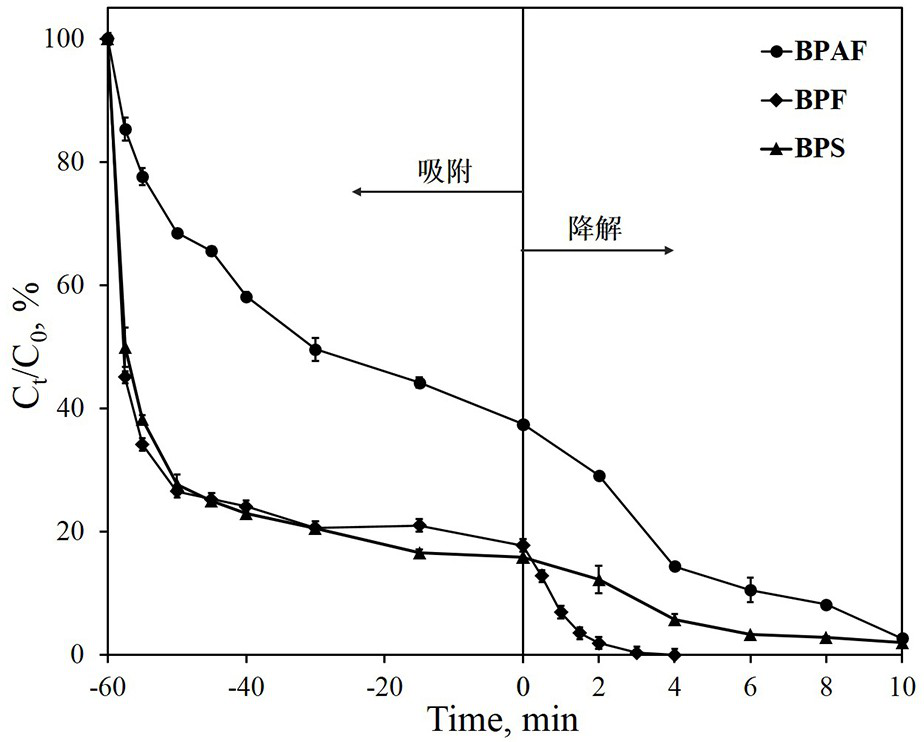

[0030] Evenly disperse the nucleic acid extracted from baker's yeast cells by concentrated salt method in 20-100 mL deionized water, slowly add 0.1-0.2 mol / L cobalt nitrate hexahydrate solution while stirring, and continue stirring for 5-12 h, The resulting complex was centrifuged, washed with water, and dried in a freeze dryer. Mix the dried complex with 1-10 times the mass of sodium chloride and potassium chloride, grind it into powder, transfer it to a corundum crucible, and place it in a tube furnace for calcination under a protective atmosphere at a calcination temperature of 900°C , the calcination time is 3-6 h, the heating rate is 5 ℃ / min, it is taken out after cooling to room temperature, and a material containing sodium chloride and potassium chloride is obtained. The resulting material was dispersed in deionized water and ultrasonically filtered and washed to remove sodium chloride and potassium chloride, dried in an oven at 60 °C, and ground into a fine powder to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com