Low-temperature normal-pressure double-effect high-salinity wastewater evaporation device and treatment method

A high-salt wastewater, double-effect evaporation technology, applied in heating water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of easy scaling, high temperature, low treatment efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

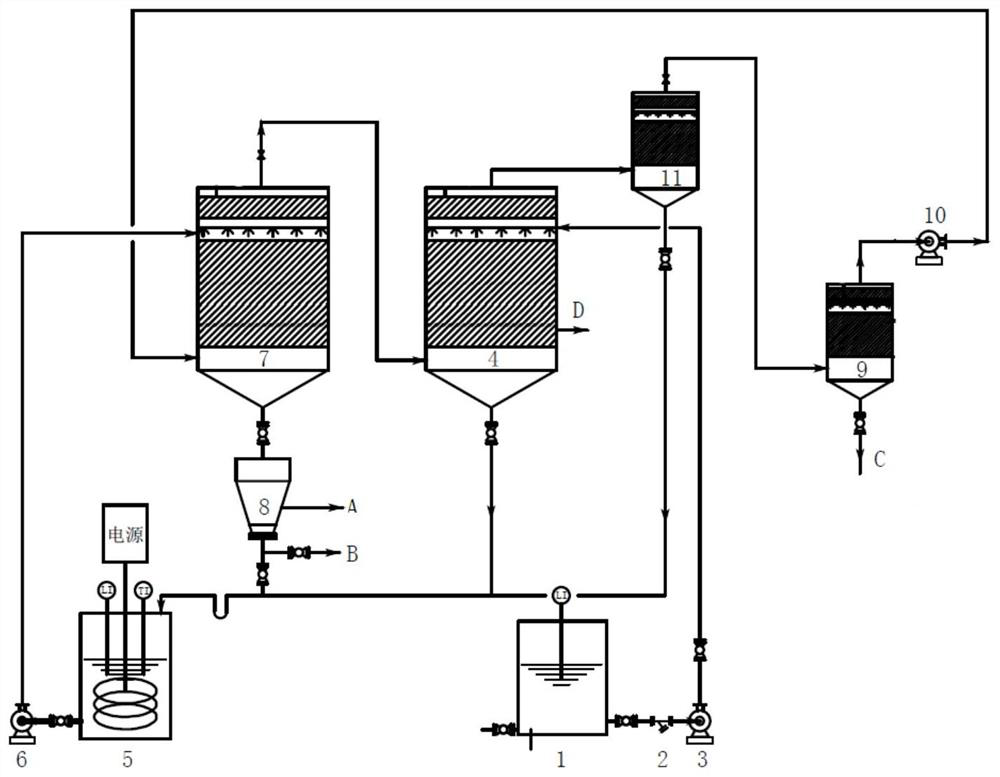

[0038] use figure 1 The method for evaporative treatment of high-salt wastewater by the device comprises the following steps:

[0039] Step 1: After the high-salt wastewater in the waste liquid pool 1 is filtered by the filter 2, the waste liquid is added to the secondary evaporator 4 by the pump 3, and the steam generated by the primary evaporator 7 is used to heat the high-salt wastewater. After the high-salt wastewater passes through the filler with high heat dissipation performance and low resistance, the surface area is enlarged to form a water film, and the high-salt wastewater is sprayed from top to bottom into the evaporation chamber of the secondary evaporation device 4, and the cold air from bottom to top Mixing, heat and mass transfer at the same time, forming humid air (when the cold air exchanges heat with high-salt wastewater, the temperature rises, the saturated vapor pressure rises, and the water vapor content rises with the rise of temperature, bringing the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com