Preparation method of polyaniline/graphene/manganese dioxide ternary composite hollow microspheres

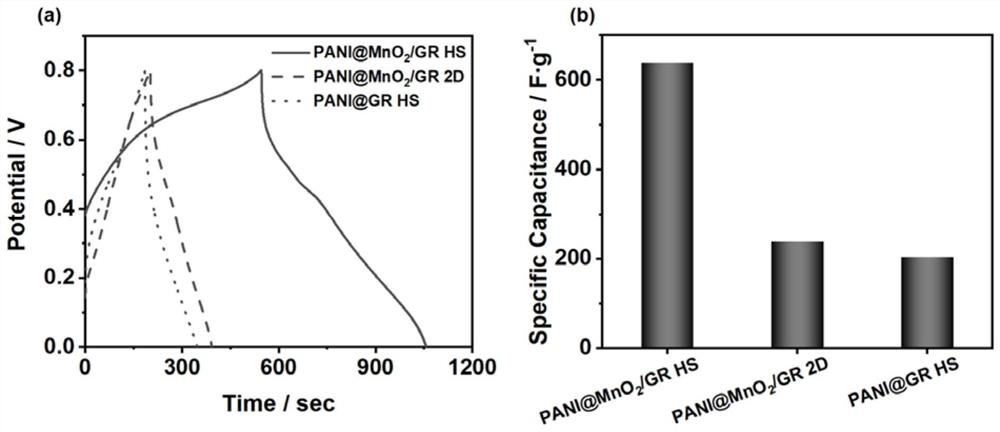

A manganese dioxide and ternary composite technology, which is applied in the field of preparation of polyaniline/graphene/manganese dioxide ternary composite hollow microspheres, can solve the problems that the specific capacitance cannot meet the expected requirements and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of polyaniline / graphene / manganese dioxide ternary composite hollow microspheres, said preparation method comprising the steps of:

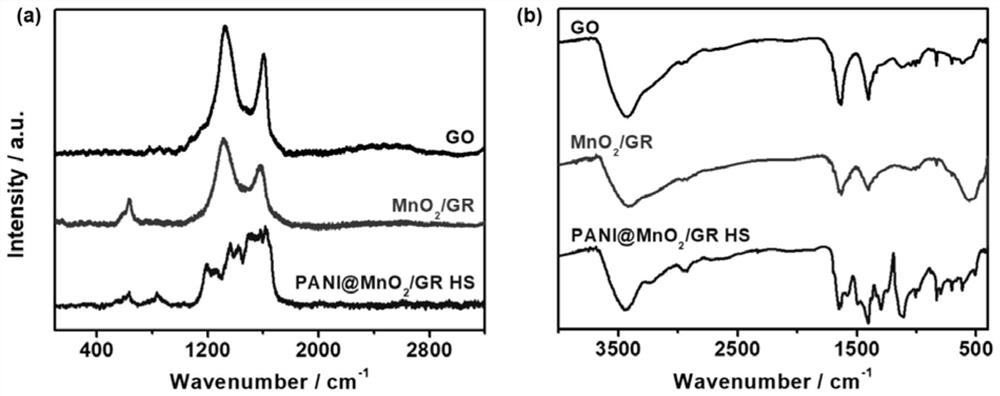

[0032] (1) Preparation of manganese dioxide-modified graphene oxide (MnO 2 / GR);

[0033] 100mg graphene oxide was dispersed in 50mL 20vol% aqueous ethanol solution to form a 2mg / mL graphene oxide dispersion; 500mg MnSO 4 ·H 2 O with 500 mg KMnO 4 Dissolve in 5mL water respectively, MnSO 4 ·H 2 O aqueous solution was added dropwise into the graphene oxide dispersion, and after an interval of 60 min, the KMnO 4 The aqueous solution was added dropwise into the graphene oxide dispersion, the reaction was continued at room temperature for 60 minutes, and finally manganese dioxide-modified graphene oxide was obtained by suction filtration and washing;

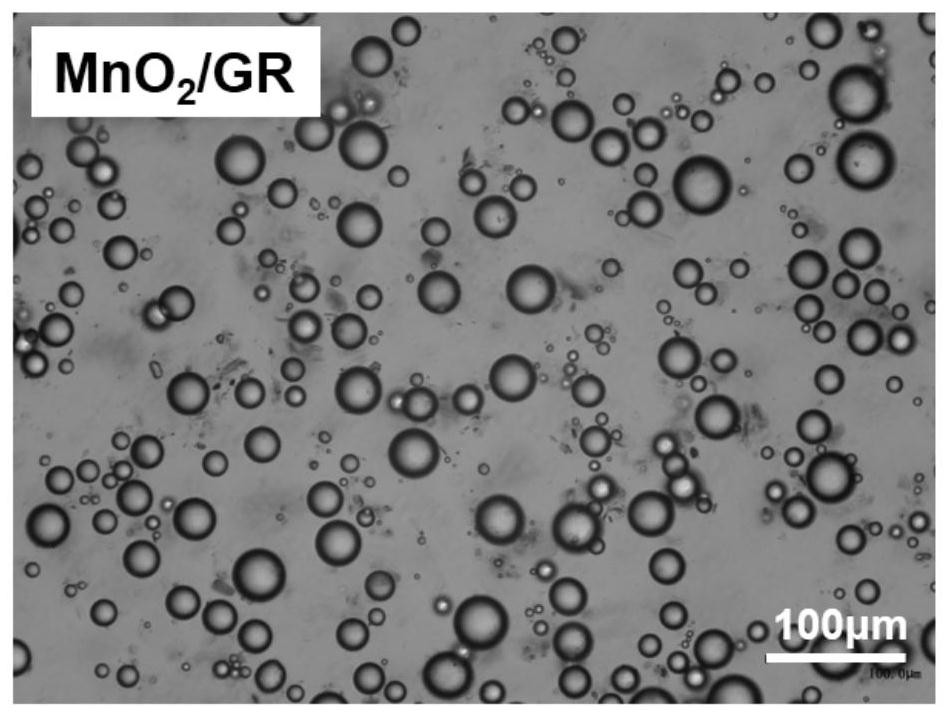

[0034] (2) Prepare oil-in-water Pickering emulsion with manganese dioxide-modified graphene oxide as particle emulsifier;

[0035] The manganese dioxide modified graph...

Embodiment 2

[0038] A preparation method of polyaniline / graphene / manganese dioxide ternary composite hollow microspheres, said preparation method comprising the steps of:

[0039] (1) Preparation of manganese dioxide-modified graphene oxide (MnO 2 / GR);

[0040] Disperse 100mg graphene oxide in 40mL 50vol% ethanol aqueous solution, form the graphene oxide dispersion liquid of 2.5mg / mL; Dissolve 10mg MnSO 4 ·H 2 O with 10 mg KMnO 4 Dissolve in 5mL water respectively, MnSO 4 ·H 2 O aqueous solution was added dropwise into the graphene oxide dispersion, and after an interval of 20 min, the KMnO 4 The aqueous solution was added dropwise into the graphene oxide dispersion, the reaction was continued at room temperature for 20 minutes, and finally manganese dioxide-modified graphene oxide was obtained by suction filtration and washing;

[0041] (2) Prepare oil-in-water Pickering emulsion with manganese dioxide-modified graphene oxide as particle emulsifier;

[0042] The manganese dioxide ...

Embodiment 3

[0046] A preparation method of polyaniline / graphene / manganese dioxide ternary composite hollow microspheres, said preparation method comprising the steps of:

[0047] (1) Preparation of manganese dioxide-modified graphene oxide (MnO 2 / GR);

[0048] 100mg graphene oxide was dispersed in 20mL 30vol% ethanol aqueous solution to form a 5mg / mL graphene oxide dispersion; 78mg MnSO 4 ·H 2 O with 73mg KMnO 4 Dissolve in 5mL water respectively, MnSO 4 ·H 2 O aqueous solution was added dropwise into the graphene oxide dispersion, and after an interval of 30 min, the KMnO 4 The aqueous solution is added dropwise in the graphene oxide dispersion, and the reaction continues for 30 min at room temperature, and finally the graphene oxide modified by manganese dioxide is obtained through suction filtration and washing; the water contact angle and TGA of the obtained material and graphene oxide are respectively as follows: Figure 4 , Figure 5 shown by Figure 4 It can be seen that m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com