A kind of nanocellulose-based composite membrane and its preparation method and use

A nanocellulose and nanofiber technology, applied in the field of materials, can solve the problems of single function, low strength of pure nanocellulose membrane, restricting the development of nanocellulose, etc., to expand the application range, excellent humidity response ability, and realize high value The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

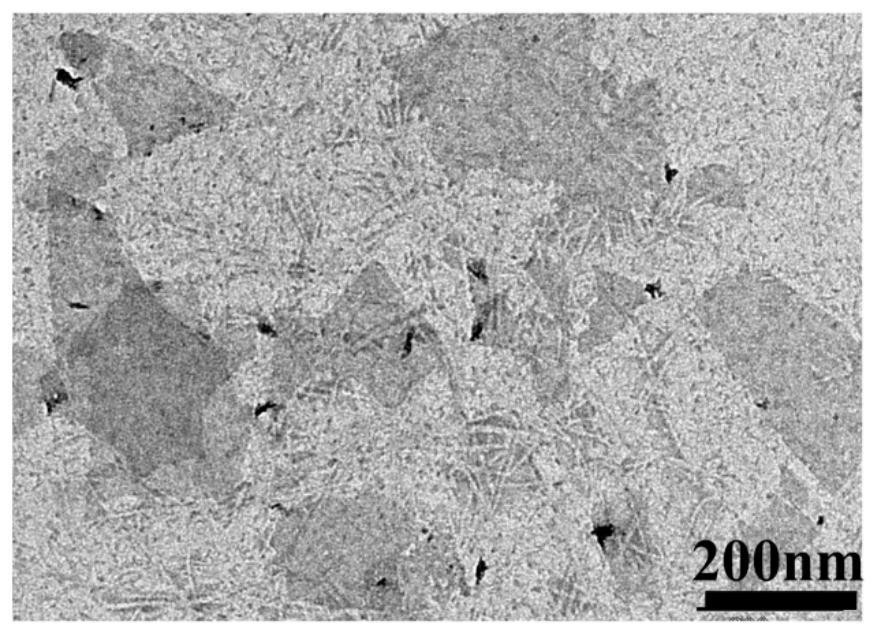

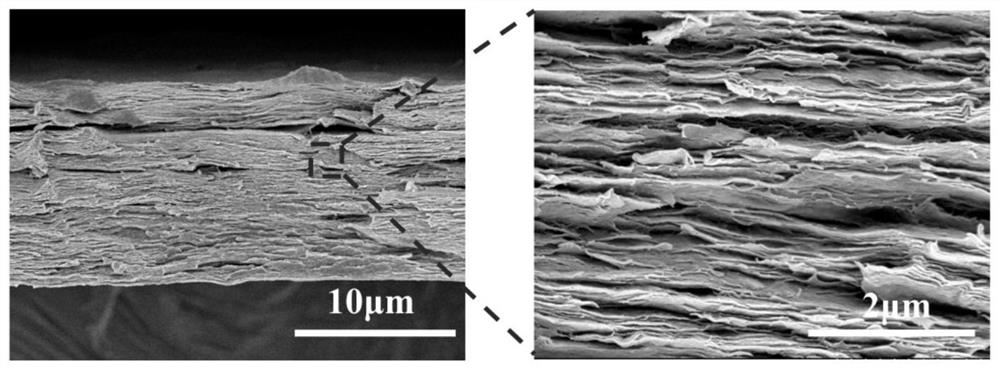

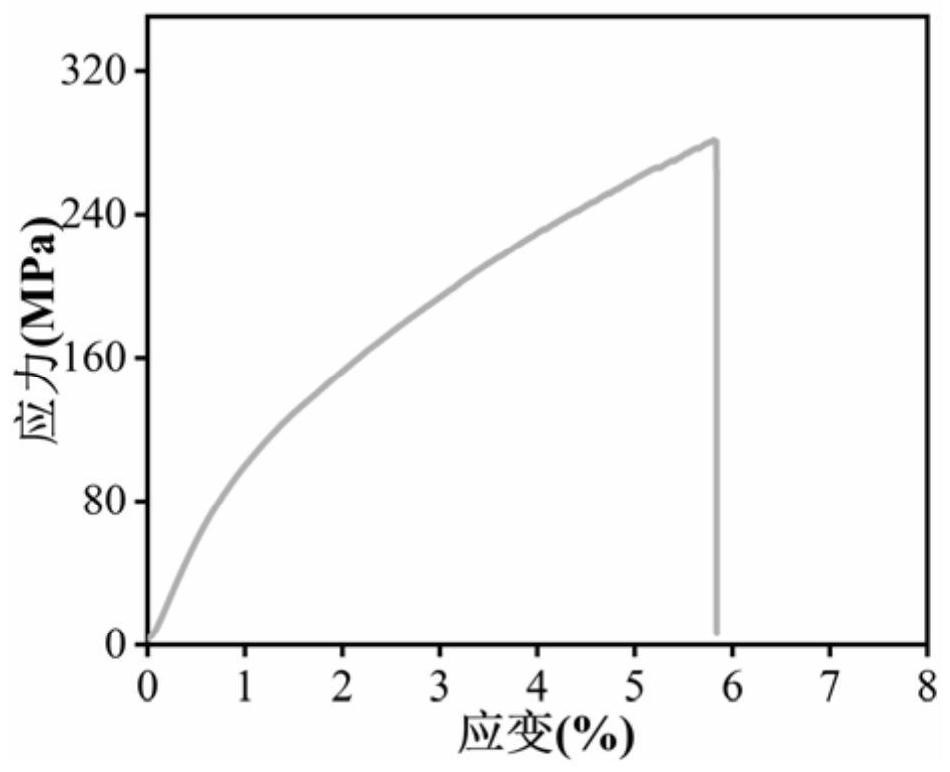

[0049] The 0.3 wt% aqueous solution of micene nanosheets and the 0.3 wt% aqueous nanofiber dispersion liquid are stirred and mixed according to the macene content of 75% to obtain a uniform nanofiber-micene nanosheet mixed solution; then, the tannic acid solution is mixed. Drop into the mixed solution of nanofiber filaments and micene nanosheets, the mass of tannic acid is 2.5% of that of nanocellulose, and stir at room temperature for 6-12 hours to obtain a uniform mixed solution; take 12 ml of the uniform mixed solution and place it in a Vacuum filtration in the filter cup, natural drying for 6 hours, and carefully peeled off from the polytetrafluoroethylene filter membrane to obtain a nanocellulose composite membrane with a thickness of 15 μm. The nanocellulose composite membrane has a mechanical strength of up to 260 MPa, bends 180° in 6s in response to humidity stimuli, and has Joule heating and antibacterial capabilities. It can be used as smart clothes to effectively di...

Embodiment 2

[0051] The nanocellulose composite film was prepared according to the same procedure as in Example 1, except that the mass of tannic acid was 5% of the nanocellulose. The mechanical strength of the nanocellulose composite membrane can reach 275.4MPa, and it can bend 180° in 3.5s in response to humidity stimulation, and can achieve a temperature increase of 17°C by applying a voltage of 5V, and is resistant to Escherichia coli and Staphylococcus aureus. Applying it to smart clothes can effectively dissipate moisture and lower the temperature by 1.8°C in summer or during vigorous exercise; supply voltage in winter to achieve thermal insulation.

Embodiment 3

[0053] The nanocellulose composite membrane was prepared according to the same procedure as in Example 1, except that the mass of tannic acid was 10% of the nanocellulose. The nanocellulose-based composite membrane has a mechanical strength of up to 248.2 MPa, bends 180° in 4.5 s in response to humidity stimuli, and has Joule heating and antibacterial capabilities. Applying it to smart clothes can effectively dissipate moisture and lower the temperature by 1.5 °C in summer or during vigorous exercise; in winter, supply voltage can achieve thermal insulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com