Preparation method of superfine high-purity gamma-aluminum oxide

An alumina, fine and high technology, which is applied in the field of preparation of ultra-fine and high-purity γ-alumina, can solve the problems of low production efficiency and low product purity, and achieve the effects of convenient operation, high material purity and high reaction product purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

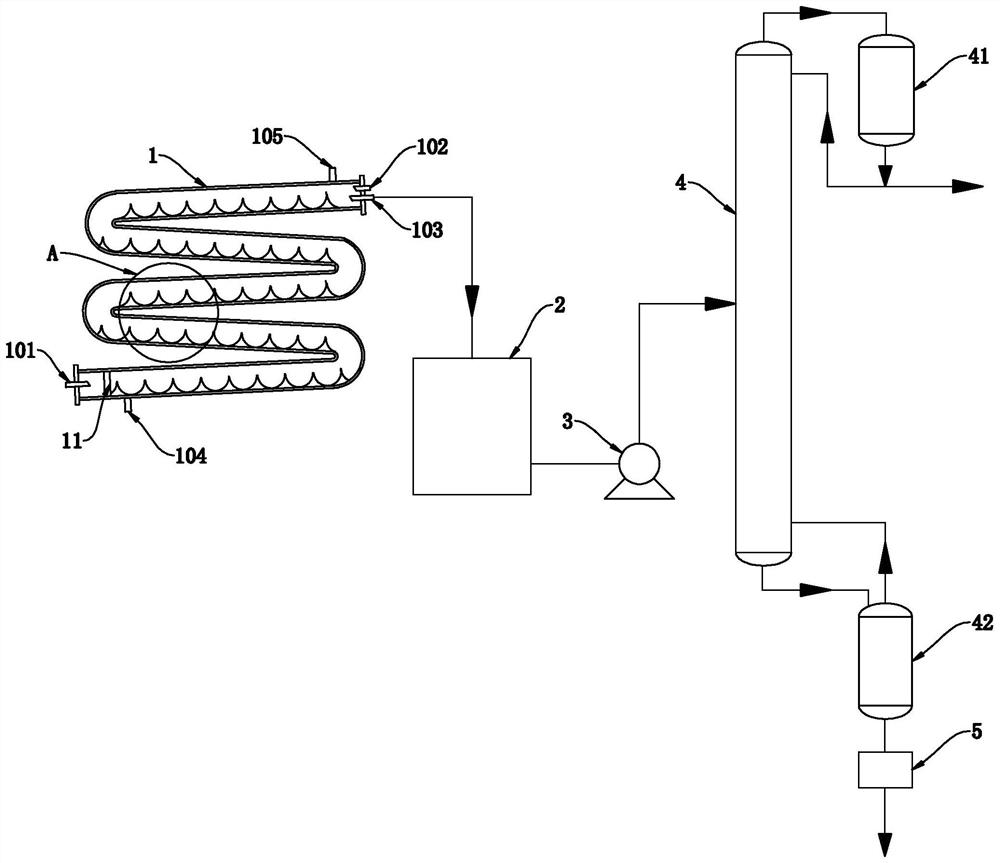

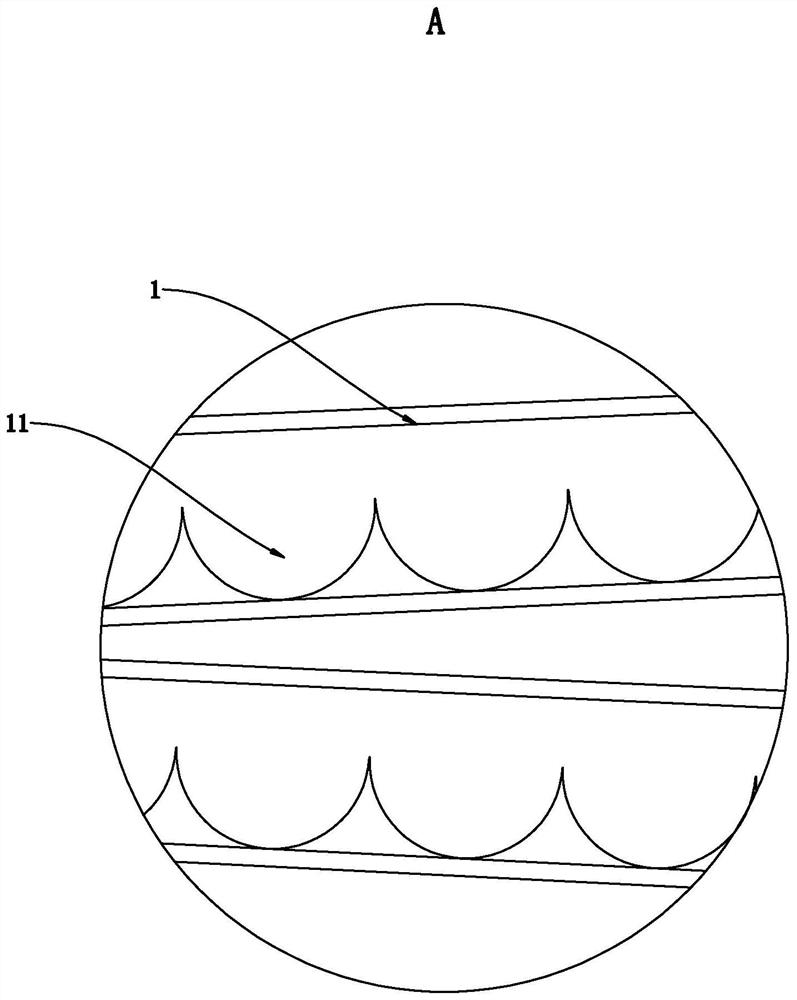

[0026] Such as figure 1 and figure 2 As shown, the preparation method of the ultrafine high-purity gamma-alumina of the present embodiment comprises the following steps:

[0027] First, inject 10kg of aluminum particles into the micro-mixing reaction zone of the channel reactor through the metal aluminum inlet of the channel reactor, the average particle size is 5mm, and the aspect ratio of the channel reactor is 20:1, and then pass through the channel reaction Put 40g of catalyst aluminum isopropoxide into the metal aluminum inlet of the reactor; then heat to 50°C, pump isopropanol through the isopropanol inlet of the channel reactor at a rate of 1L per hour, and heat up to 85°C after 5 minutes of reaction The continuous reflux reaction is carried out in the micro-mixing reaction zone in the channel reactor, and the qualified aluminum isopropoxide and isopropanol mixed liquid appears at the outlet of the reaction product of the channel reactor after 60 minutes of feeding. ...

Embodiment 2

[0033] The preparation method of ultrafine high-purity gamma-alumina of the present embodiment, it comprises the following steps:

[0034] First, inject 10kg of aluminum particles into the micro-mixing reaction zone of the channel reactor through the metal aluminum inlet of the channel reactor, with an average particle size of 5mm, and the aspect ratio of the channel reactor is 25:1, and then pass through the channel reaction Add 40g of catalyst (aluminum isopropoxide or tri-n-propylaluminum) to the metal aluminum inlet of the reactor; then heat to 50°C and pump isopropanol through the isopropanol inlet of the channel reactor at a rate of 1 L per hour After reacting for 5 minutes, the temperature was raised to 85°C for continuous reflux reaction in the micro-mixed reaction zone in the channel reactor, and after 72 minutes of passing through the reaction product outlet of the channel reactor, a mixed liquid of qualified aluminum isopropoxide and isopropanol appeared. The temper...

Embodiment 3

[0040] The preparation method of ultrafine high-purity gamma-alumina of the present embodiment, it comprises the following steps:

[0041] First, inject 10kg of aluminum particles into the micro-mixing reaction zone of the channel reactor through the metal aluminum inlet of the channel reactor, the average particle size is 5mm, and the aspect ratio of the channel reactor is 30:1, and then pass through the channel reaction Add 40g of catalyst (aluminum isopropoxide or tri-n-propylaluminum) to the metal aluminum inlet of the reactor; then heat to 50°C and pump isopropanol through the isopropanol inlet of the channel reactor at a rate of 1 L per hour After reacting for 5 minutes, the temperature was raised to 85°C for continuous reflux reaction in the micro-mixing reaction zone in the channel reactor, and after 88 minutes, a qualified aluminum isopropoxide and isopropanol mixed liquid appeared at the outlet of the reaction product of the channel reactor. The temperature of the ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com