Cross-linked hyaluronic acid gel

A technology of cross-linking hyaluronic acid and hyaluronic acid, which is applied in medical science, pharmaceutical formulations, prostheses, etc., and can solve problems such as degradation of hyaluronic acid, failure to meet performance requirements, and harsh process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

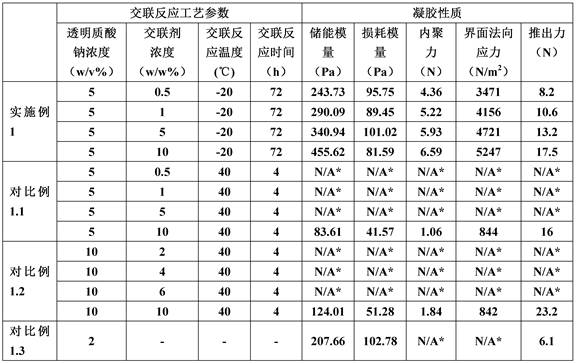

Embodiment 1

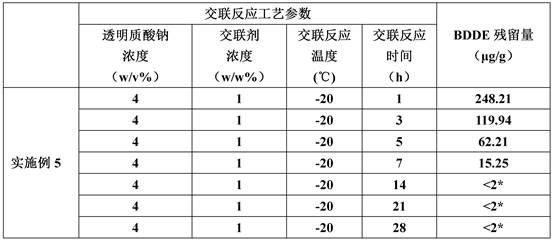

[0134] The preparation method is as follows, wherein the sodium hyaluronate concentration is 5 w / v%, the sodium hydroxide concentration is 1 w / v%, the heterogeneous system formation temperature is -20°C, the holding time is 2h, the crosslinking reaction temperature is -20°C, and the reaction time is 3 days.

[0135] Prepare 20 ml of 1 w / v% sodium hydroxide aqueous solution, add the cross-linking agent BDDE according to the concentration shown in Table 1, mix well and add 1 g of sodium hyaluronate to it. The solution was stirred until uniform, then kept at -20°C for 2 hours, and then placed at -20°C for 3 days. After the reaction is completed, place the product at room temperature until the ice crystals are completely melted, adjust the pH to neutral with hydrochloric acid solution, put it in PBS buffer solution, dialysis, purify, swell and mechanically homogenize to obtain a cross-linked sodium hyaluronate gel. 20mg / ml.

Embodiment 2

[0148] Example 2: The preparation method is as follows, wherein the crosslinking agent concentration is 1.5 w / w%, the sodium hydroxide concentration is 2 w / v%, the heterogeneous system formation temperature is -25°C, the holding time is 1h, the crosslinking reaction temperature is -20°C, The cross-linking reaction time is 3 days.

[0149] Prepare 5ml of 2 w / v% sodium hydroxide aqueous solution, add the crosslinking agent BDDE according to the concentration shown in Table 2, mix well and add sodium hyaluronate powder to the concentration shown in Table 2. The solution was stirred until homogeneous and kept at -25°C for 1 h, then at -20°C for 3 days. After the reaction is completed, place the product at room temperature until the ice crystals are completely melted, adjust the pH to neutral with hydrochloric acid solution, put it into PBS buffer solution for dialysis purification and mechanical homogenization, and obtain a cross-linked sodium hyaluronate gel. 20 mg / ml. For the ...

Embodiment 3

[0157] Example 3: The preparation method is as follows, wherein the concentration of sodium hyaluronate is 10 w / v%, the concentration of sodium hydroxide is 1 w / v%, the concentration of crosslinking agent BDDE is 1 w / w%, and the heterogeneous system formation temperature is -30°C. The holding time is 2h, and the crosslinking reaction time is 3 days.

[0158] Prepare 10 ml of 1 w / v% sodium hydroxide aqueous solution, add 0.01 g of cross-linking agent BDDE, mix well and add 1 g of sodium hyaluronate. The solution was stirred until uniform, then kept at -30°C for 2h, and then placed at the temperature in Table 3 for 3 days. After the reaction was completed, the product was placed at room temperature until the ice crystals were completely melted, adjusted to neutral pH with hydrochloric acid solution, dialyzed and purified in PBS buffer and mechanically homogenized to obtain a cross-linked sodium hyaluronate gel with a concentration of 20 mg / ml.

[0159] The cross-linked sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion | aaaaa | aaaaa |

| cohesion | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com