Polylactic acid-based foaming particles and preparation method thereof

An expanded particle, polylactic acid-based technology, applied in the field of plastic foam materials, can solve the problems of high cost and high price of PLA foam beads, unfavorable for the popularization and application of PLA, etc., and achieves low equipment requirements, high expansion ratio and environmental protection. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

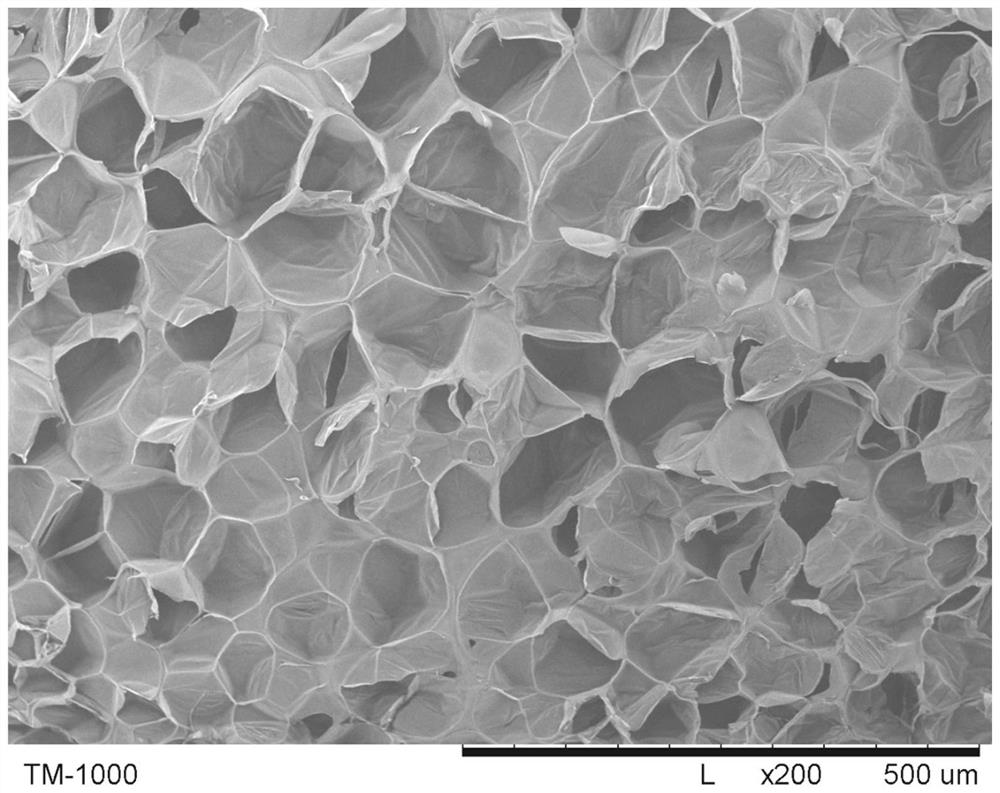

[0063] The semi-crystalline PLA was added to a twin-screw extruder to extrude and granulate, and the diameter of PLA pellets was 1.0mm. The prepared PLA particles were put into an autoclave, and the pressure was 5MPa of CO 2 , Make the PLA particles reach saturation, the saturation temperature is 25°C, the saturation time is 16h, release the pressure, and take out the saturated PLA particles. The saturated PLA particles have a gas solubility of 18 (gCO 2 / kg PLA), crystallinity is 15%, puts into the oven of 80 ℃ and expands for 30s, obtains PLA primary expanded particle, and crystallinity is 25%, and expansion ratio is 23.

[0064] Put the prepared PLA primary foamed particles into an autoclave, and feed CO with a pressure of 4.0MPa. 2 , the saturation temperature is 25°C, the saturation time is 8h, the pressure is released, and the saturated primary foamed PLA particles are taken out. The saturated PLA primary foam particles have a gas solubility of about 20 (gCO 2 / kg pr...

Embodiment 2

[0066] In this example, except that the pressure of secondary saturation is 6MPa, the saturation time is 4h, and the gas solubility after secondary saturation is about 20 (gCO 2 / kg primary expanded particle), crystallinity is about 30%, and foaming temperature is 120 ℃, and other conditions are the same as embodiment 1, and the PLA secondary expanded particle of preparation, expansion ratio is 41.

Embodiment 3

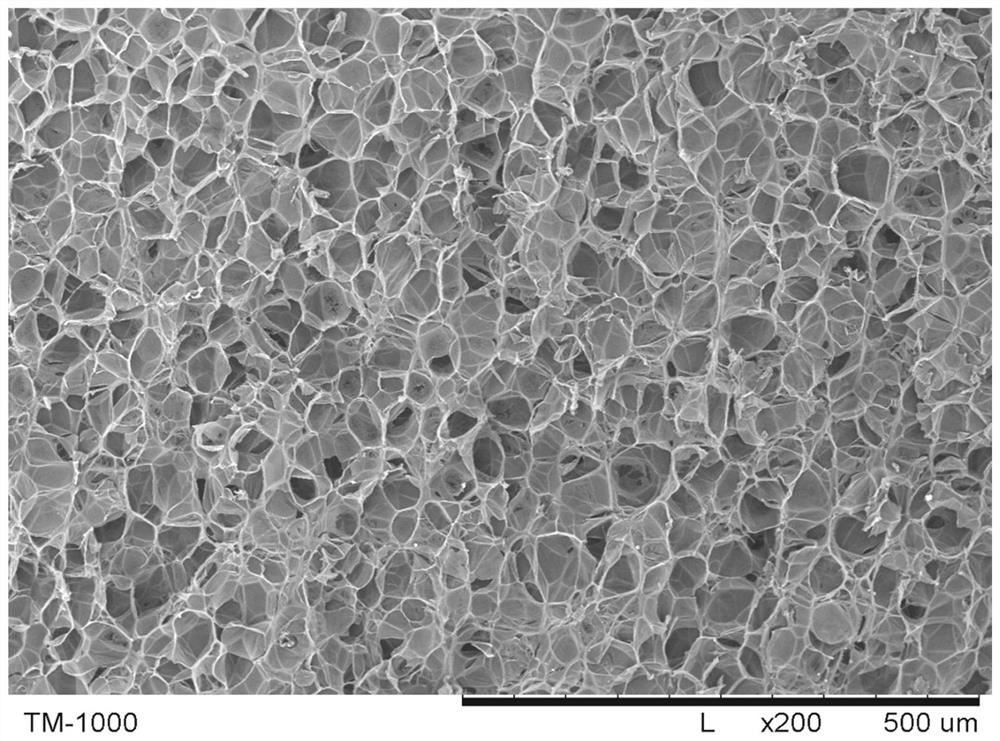

[0068] Mix the semi-crystalline PLA and nano-silica in a high-speed mixer, and then add them to a twin-screw extruder to extrude and granulate. In this embodiment, except that the particles are PLA / nano-silicon dioxide composite material, the amount of nano-silicon dioxide added is 0.5 wt%. Other conditions are with embodiment 1, and the PLA / nano silicon dioxide particle after primary saturation, its gas solubility is about 16 (gCO 2 / kg PLA / nano silicon dioxide particles), the crystallinity is about 18%, the particle after primary foaming, the crystallinity is about 28%, and the expansion ratio is 30. The gas solubility after secondary saturation is about 20(gCO 2 / kg primary expanded particle), crystallinity is about 29%, obtains secondary expanded particle, and expansion ratio is 45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap