Antifouling antistatic high-wear-resistant transparent photocureable coating and preparation method thereof

A light-curing coating, high wear-resistant technology, used in antifouling/underwater coatings, conductive coatings, coatings, etc. Electrostatic efficiency, excellent antistatic performance, and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] A kind of preparation method of described a kind of antifouling antistatic high wear-resistant transparent light-cured coating, comprises the following steps:

[0058] Step 1. Preparation of high wear-resistant and anti-fouling main resin:

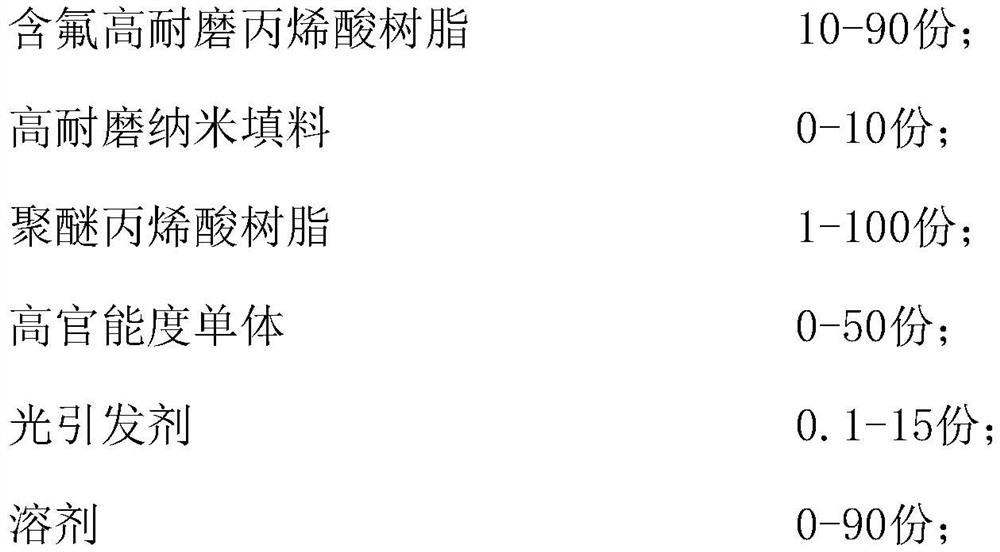

[0059] Prepare 10-90 parts of fluorine-containing high wear-resistant acrylic resin, 0-10 parts of high wear-resistant nano-filler, 1-100 parts of polyether acrylic resin, 0-50 parts of high-functionality monomer, 0.1-15 parts photoinitiator, 0-90 parts of solvent;

[0060] Under normal temperature conditions, put fluorine-containing high wear-resistant acrylic resin, high wear-resistant nano filler, polyether acrylic resin, high-functionality monomer, photoinitiator, and solvent into a conventional high-speed stirring disperser in proportions by weight. , carry out high-speed stirring and dispersing to obtain a high wear-resistant and anti-fouling main resin;

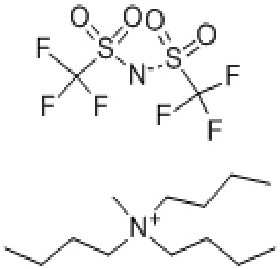

[0061] Step 2, preparation of antistatic dispersion liquid:

[0062]...

Embodiment 1

[0066] An antifouling, antistatic and highly wear-resistant transparent light-cured coating is prepared by the following method:

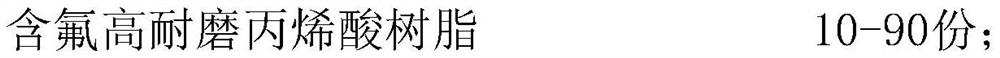

[0067] Preparation method: Step 1. Preparation of high wear-resistant and anti-fouling main resin: The raw materials are composed of the following components in parts by weight:

[0068]

[0069] Mix the above components in proportion, stir and disperse at high speed in a high-speed stirring disperser, and then prepare a high wear-resistant and anti-fouling main resin;

[0070] Step 2, the preparation of antistatic dispersion liquid, the raw material is made up of the following components in parts by weight:

[0071] 10 parts of tri-n-butylmethylammonium bistrifluoromethylsulfonimide salt;

[0072] 10 parts of nonionic fluorosurfactant;

[0073] 80 parts of isopropanol;

[0074] Mix the above components in proportion, and carry out high-speed stirring and dispersing in a high-speed stirring disperser to prepare an antistatic dispersion liquid...

Embodiment 2

[0080] An antifouling, antistatic and highly wear-resistant transparent light-cured coating is prepared by the following method:

[0081] Preparation method: Step 1. Preparation of high wear-resistant and anti-fouling main resin: The raw materials are composed of the following components in parts by weight:

[0082]

[0083] Mix the above components in proportion, stir and disperse at high speed in a high-speed stirring disperser, and then prepare a high wear-resistant and anti-fouling main resin;

[0084] Step 2, preparation of antistatic dispersion liquid: the raw materials are composed of the following components in parts by weight:

[0085] 10 parts of 1-ethyl-3-methylimidazole bis-trifluoromethanesulfonate;

[0086] 5 parts of anionic fluorosurfactant;

[0087] 85 parts of butanol;

[0088] Mix the above components in proportion, and carry out high-speed stirring and dispersing in a high-speed stirring disperser to prepare an antistatic dispersion liquid;

[0089] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com