Method for manufacturing film laminate having print layer

A manufacturing method and film lamination technology, applied in chemical instruments and methods, coating, lamination, etc., can solve problems such as film curling, and achieve the effect of high pencil hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

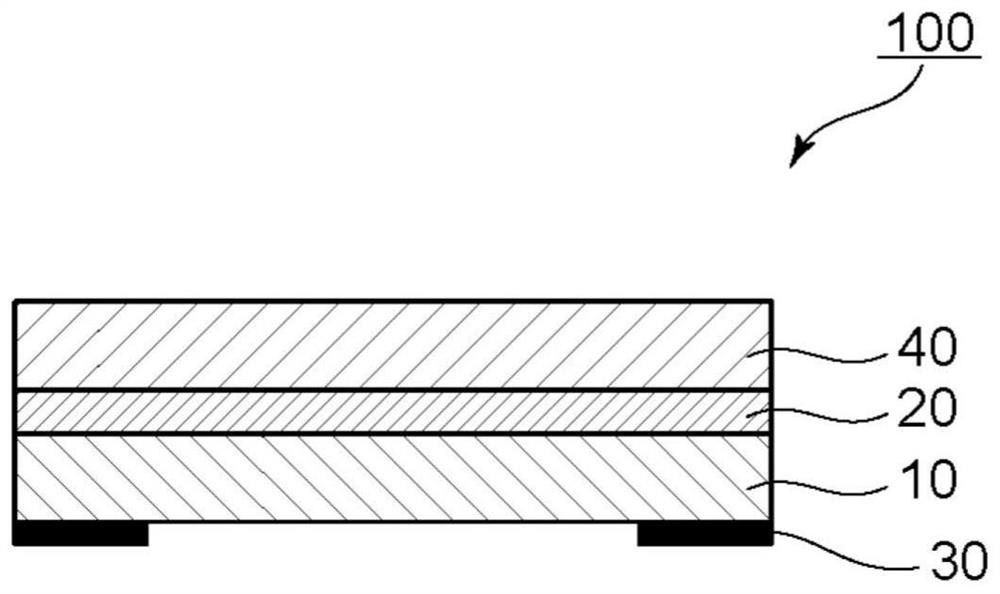

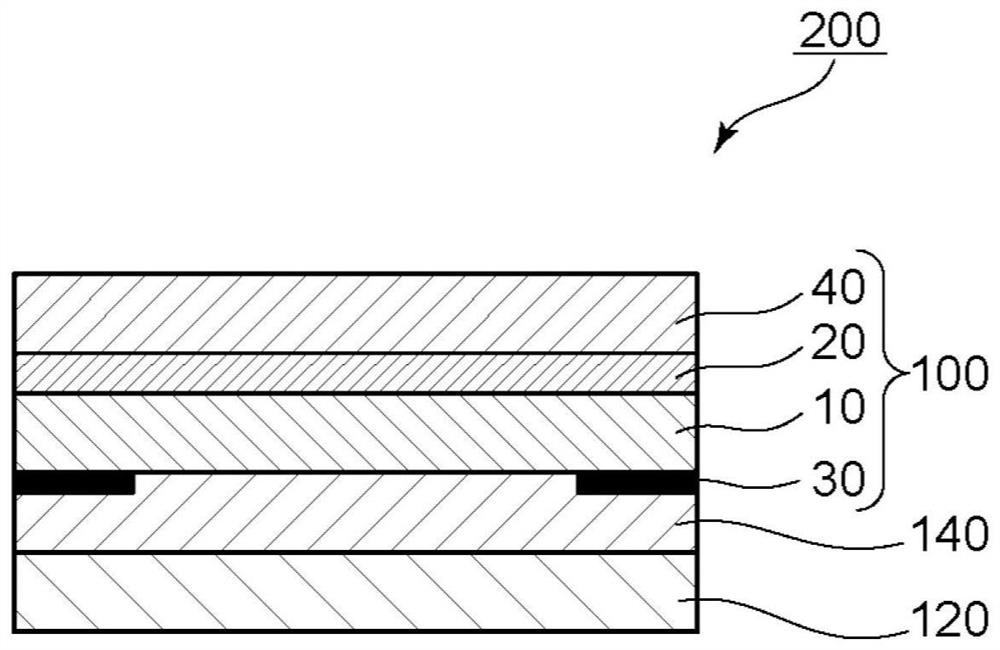

Method used

Image

Examples

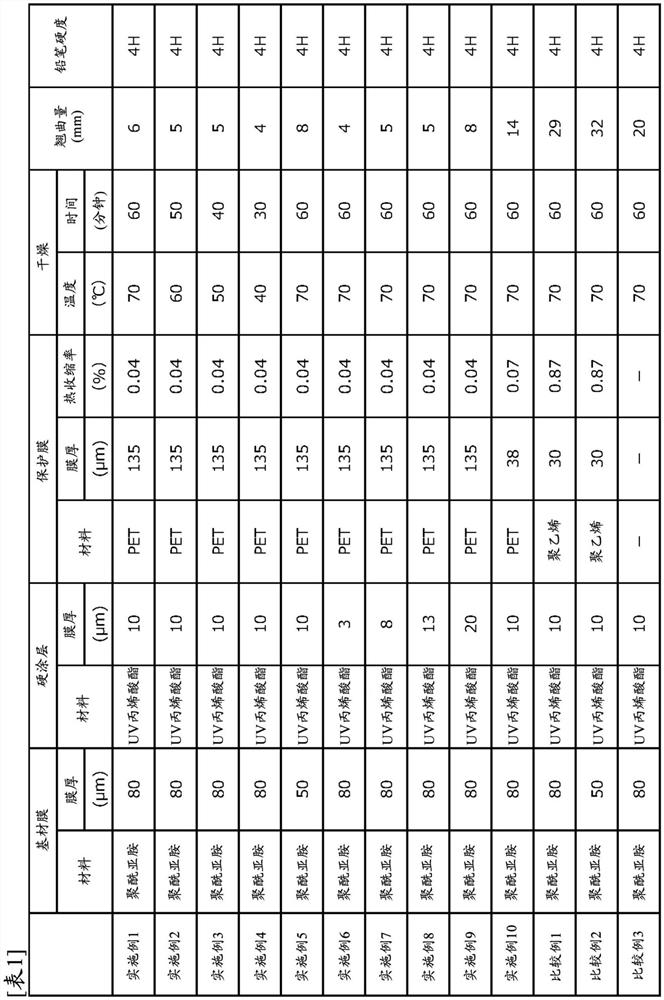

Embodiment 1

[0102] 1. Preparation of Coating Liquid for Hard Coat Formation

[0103] 100 parts by mass of an ultraviolet-curable multifunctional acrylate (manufactured by Aica Kogyo Co., Ltd., product name "Z-850-16") as a matrix resin, a leveling agent (manufactured by DIC Corporation, product name: GRANDIC PC-4100) 5 Parts by mass and 3 parts by mass of a photopolymerization initiator (manufactured by Ciba Japan Co., Ltd., trade name: IRGACURE 907) were mixed, and diluted with methyl isobutyl ketone so that the solid content concentration became 50% by mass, and prepared A coating solution for forming a hard coat layer.

[0104] 2. Production of protective film

[0105] Add 90 parts by weight of butyl acrylate (BA), 10 parts by weight of acrylic acid (AA), and 2,2'-azo 0.2 parts by weight of diisobutyronitrile, 234 parts by weight of ethyl acetate, nitrogen gas was introduced while slowly stirring, and the liquid temperature in the flask was kept at around 63°C for about 7 hours of po...

Embodiment 2

[0111] Except having performed drying at 60 degreeC for 50 minutes, it carried out similarly to Example 1, and obtained the film laminated body with a printing layer. The same evaluation as in Example 1 was performed on the obtained film laminate with a printed layer. The results are shown in Table 1.

Embodiment 3

[0113] Except having performed drying at 50 degreeC for 40 minutes, it carried out similarly to Example 1, and obtained the film laminated body with a printing layer. The same evaluation as in Example 1 was performed on the obtained film laminate with a printed layer. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com