Foam type peracetic acid disinfectant as well as preparation method and use method thereof

A foam-type peracetic acid and disinfectant technology, which is applied in botany equipment and methods, disinfectants, applications, etc., can solve the problems of unguaranteed action time, octahydroxyquinoline carcinogenicity, and reduced disinfection effect, etc., to achieve prolonged sterilization Effective time, guaranteed sterilization, good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

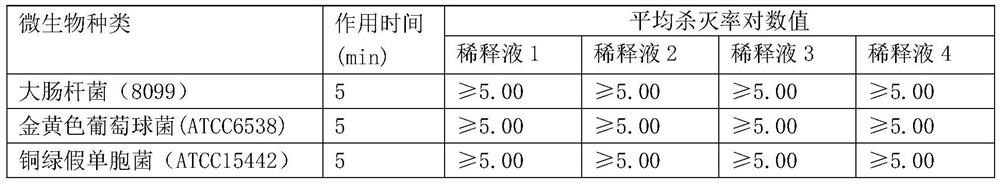

Examples

Embodiment 1

[0029] The foam type peracetic acid disinfectant that present embodiment provides comprises: the hydrogen peroxide of 35wt%, the acetic acid of 35wt%, the ethylenediaminetetramethylene phosphonic acid of 0.2wt%, the phosphoric acid of 1wt%, the dodecane of 4wt% sodium diphenyl ether disulfonate, 0.1wt% perfluoroalkyl alcohol polyoxyethylene ether phosphate amine sodium, 1wt% sodium salicylate, 1wt% sodium pyrophosphate, and the rest is water.

[0030] The preparation method of the foam type peracetic acid disinfectant provided in this embodiment is: first mix 35wt% hydrogen peroxide, 0.2wt% ethylenediamine tetramethylene phosphonic acid, 1wt% sodium salicylate, 1wt% coke Add sodium phosphate and water into the reactor, and control the temperature of the reactor at 30°C-40°C, stir, then add 35wt% of acetic acid, 1wt% of phosphoric acid, 4wt% of sodium dodecyl diphenyl ether disulfonate and 0.1 Wt% perfluoroalkyl alcohol polyoxyethylene ether phosphate amine sodium, stirring for...

Embodiment 2

[0033] The foam type peracetic acid disinfectant that present embodiment provides comprises: the hydrogen peroxide of 35wt%, the acetic acid of 40wt%, the ethylenediamine tetramethylene phosphonic acid of 0.4wt%, the sulfuric acid of 1wt%, the dodecane of 8wt% sodium diphenyl ether disulfonate, 0.5wt% perfluoroalkyl alcohol polyoxyethylene ether phosphate amine sodium, 1wt% citric acid, 2wt% sodium hexametaphosphate, and the rest is water.

[0034]The preparation method of the foam type peracetic acid disinfectant provided in this embodiment is: first mix 35wt% hydrogen peroxide, 0.4wt% ethylenediaminetetramethylenephosphonic acid, 1wt% citric acid, 2wt% hexametaphosphoric acid Add sodium and water to the reactor, and control the temperature of the reactor at 30°C-40°C, stir, then add 40wt% of acetic acid, 1wt% of sulfuric acid, 8wt% of sodium dodecyl diphenyl ether disulfonate and 0.5wt% perfluoroalkyl alcohol polyoxyethylene ether phosphate amine sodium, stirred for 24 hours...

Embodiment 3

[0037] The foam type peracetic acid disinfectant that present embodiment provides comprises: the hydrogen peroxide of 45wt%, the acetic acid of 40wt%, the ethylenediamine tetramethylene phosphonic acid of 0.2wt%, the sulfuric acid of 4wt%, the dodecane of 7wt% Sodium diphenyl ether disulfonate, 0.4wt% perfluoroalkyl alcohol polyoxyethylene ether phosphate amine sodium, 3wt% tartaric acid, 0.2wt% picolinic acid, and the rest is water.

[0038] The preparation method of the foam type peracetic acid disinfectant provided in this embodiment is: first mix 45wt% hydrogen peroxide, 0.2wt% ethylenediamine tetramethylene phosphonic acid, 3wt% tartaric acid, 0.2wt% picolinic acid Add water and water to the reactor, and control the temperature of the reactor at 30°C-40°C, stir, then add 40wt% of acetic acid, 4wt% of sulfuric acid, 7wt% of sodium dodecyl diphenyl ether disulfonate and 0.4wt% of Perfluoroalkyl alcohol polyoxyethylene ether phosphate amine sodium, stirred for 24 hours, stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com