Environment-friendly powder metallurgy process with wet separation technology

A technology of wet separation and powder metallurgy, applied in the field of powder metallurgy technology, can solve the problems of changing the composition of metal materials, easy oxidation failure, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

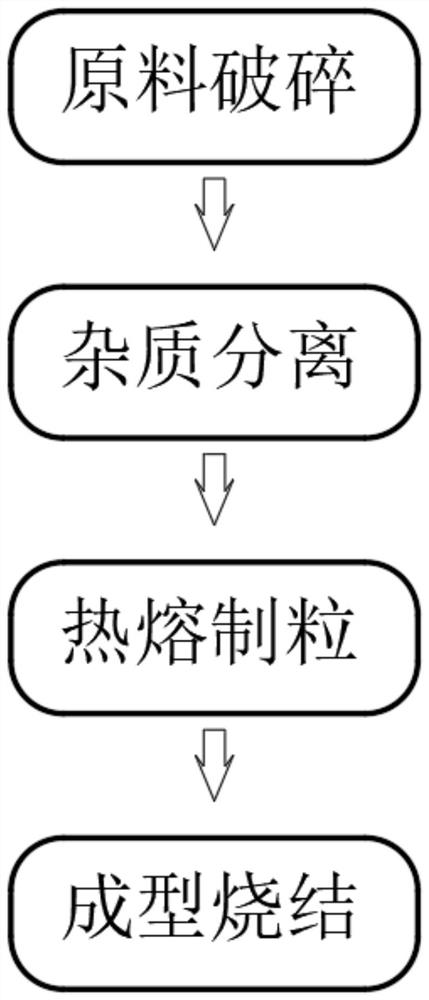

[0041] see figure 1 , an environmentally friendly powder metallurgy process with wet separation technology, its main steps include:

[0042] S1. Raw materials are crushed. Use a water gun to wash the surface of the recovered metal waste to remove dirt and other stains on the surface. After drying, use a crushing device to crush the metal waste into small pieces. In particular, before crushing the metal waste, First use compression and compress the metal waste into a cube or cake-shaped three-dimensional structure, so that the broken pieces of metal waste can easily become regular shapes, which is convenient for follow-up work;

[0043] S2, impurity separation, put the metal waste pieces processed in step S1 into the wet separation equipment, use ultrasonic technology to separate the metal waste from the coating on the surface of the metal waste and the impurities of the paint, and separate the target metal waste from the above-mentioned Separation of impurities to obtain high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com