Reactor for preparing synthesis gas by reforming liquid fuel through plasma and application

A liquid fuel and reactor technology, applied in the field of ionic chemistry, can solve the problems of unstable discharge, reduce the reliability and service life of the reactor, and achieve the effects of long residence time, avoiding carbon deposition, and avoiding unstable discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

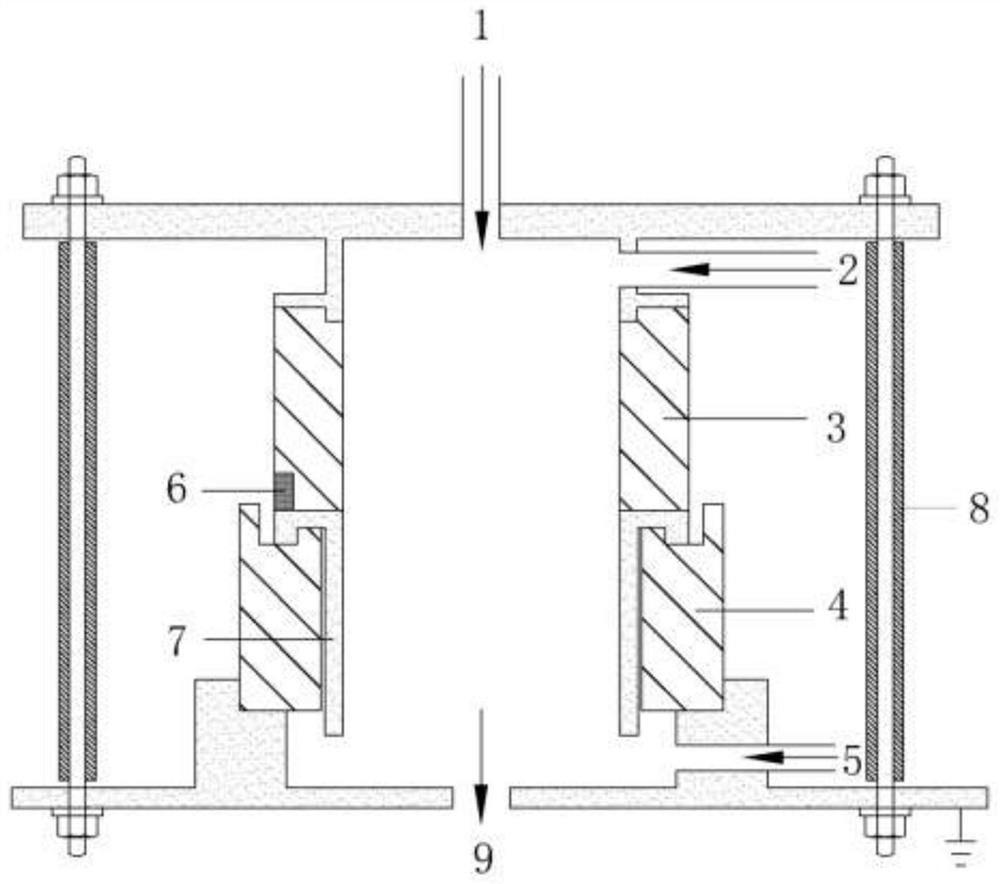

[0024] A reactor for preparing synthesis gas by plasma reforming liquid fuel, including a hollow circular cylinder made of insulating material with upper and lower ends open, an upper sealing cover is arranged at the upper opening end of the cylinder, and the upper sealing cover and the cylinder The upper opening end of the cylinder body is airtightly connected, and the lower opening end of the cylinder body is provided with a lower sealing cover made of conductive material, and the lower sealing cover is airtightly connected with the lower opening end of the cylinder body; Hollow cylindrical high-voltage electrode, there is a gap between the outer wall of the high-voltage electrode and the inner wall of the cylinder, there is a gap between the end face of the lower opening of the high-voltage electrode and the lower sealing cover, the high-voltage electrode is connected to the high-voltage output end of the external high-voltage power supply, and the lower seal The cover is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com