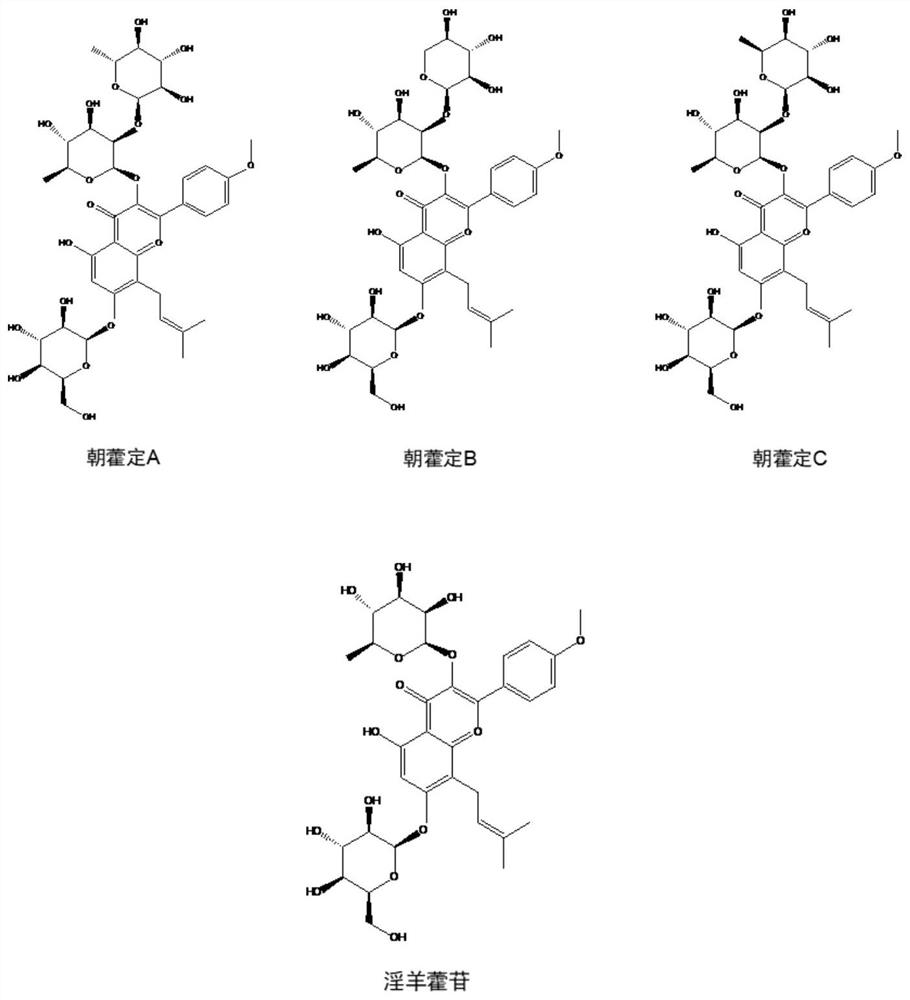

Method for preparing icariin by using biphasic enzymatic reaction

A technology of icariin and enzymatic reaction, applied in the direction of fermentation, etc., can solve the problems of unsteady, sustainable and effective reaction process, waste of enzyme resources, etc., and achieve the effect of saving enzyme cost, high yield, and reducing the amount of enzyme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The enzyme preparation product that adopts in this patent is to form through liquid submerged fermentation purification and refinement by fungal strain, purchased from sunson Xiasheng Enzyme Preparation Co., Ltd. α-L-rhamnosidase (α-L-rhamnosidase, EC 3.2.1.40) is a hydrolase, which mainly acts on α-1,2, α-1,3, α-1,4, α- The 1,6 and α1-linked glycosidic bonds can hydrolyze the non-reducing α-L-rhamnosidic bond bound to the terminal of the substrate, releasing rhamnose and the corresponding ligand at the same time. The enzyme complies with GB1886. 174-2016 "National Food Safety Standard Enzyme Preparations for Food Industry". The enzyme of this product is a light yellow-brown powder preparation, without the enzyme activity of other components. Enzyme activity of this product: see product inspection report. The optimum temperature for enzyme products is 45°C-60°C, and the effective temperature is 40°C-65°C. PH value: the optimum pH value is 4.0-5.0, and the effective p...

Embodiment 2

[0071] Compared with Example 1, the present embodiment is only different in that the protective agent "starch" is removed.

[0072] (1) Preparation of Epimedium extract: Get crushed Epimedium and add 70% ethanol for extraction, the ratio of solid to liquid is 1:30, concentrate and dry under reduced pressure to obtain Epimedium extract;

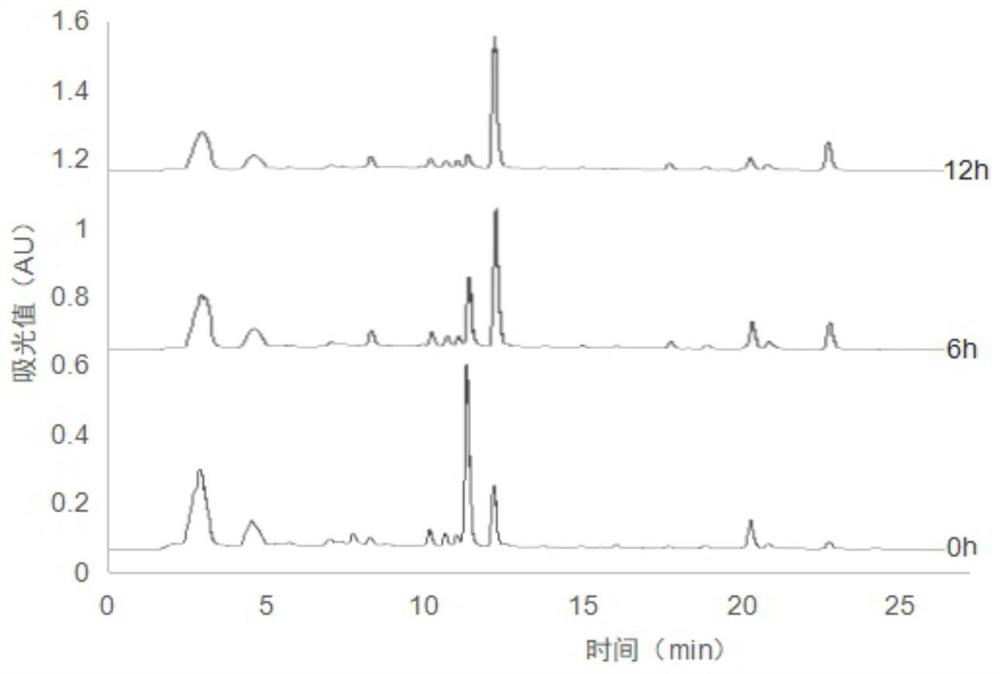

[0073] (2) Two-phase enzymatic hydrolysis reaction: first add an appropriate amount of buffer to the enzyme coated with starch, stir in a water bath at 40°C for 30 minutes, then centrifuge at 5000 rpm for 10 minutes to remove the starch in the enzyme preparation, and perform the following reaction. Add the enzyme / Epimedium extract in 1:5 (g / g) to the chloroform / buffer (1:10) reaction system, and the solid-liquid ratio is 1:10. After shaking and mixing, carry out enzymatic hydrolysis reaction. Sampling and detection according to the reaction time, when the conversion rate of Epimedin C reaches more than 95% (the content of Epimedin C in the ra...

Embodiment 3

[0084] Compared with Example 1, this example differs only in the use of different organic phases.

[0085] (1) Preparation of Epimedium extract: Get crushed Epimedium and add 70% ethanol for extraction, the ratio of solid to liquid is 1:30, concentrate and dry under reduced pressure to obtain Epimedium extract;

[0086] (2) Two-phase enzymatic hydrolysis reaction: add starch-coated enzyme / Epimedium extract at 1:5 (g / g) to n-butanol / buffer (1:10) reaction system, solid-liquid The ratio is 1:10. After shaking and mixing, the enzymatic hydrolysis reaction was carried out. Sampling and detection according to the reaction time, when the conversion rate of Epimedin C reaches more than 95% (the content of Epimedin C in the raw material itself is relatively high, so for the accuracy of the data, the conversion rate of Epimedin C is used as the judgment of the reaction end point), Finish the reaction, cool to room temperature, separate the n-butanol phase and the buffer phase through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com