Method for preparing ultra-thick three-dimensional porous copper micro-film

A technology of porous copper and copper electrodes, applied in jewelry and other directions, can solve the problems of easy peeling thickness, loose coating, and inconspicuous three-dimensional structure of the coating, and achieve the effects of short preparation time, strong binding force, and not easy self-loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

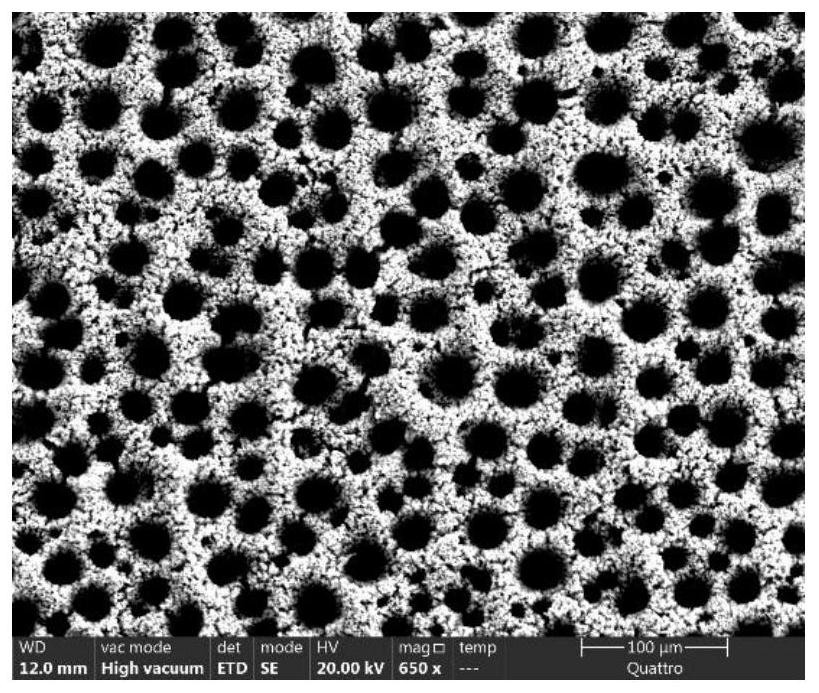

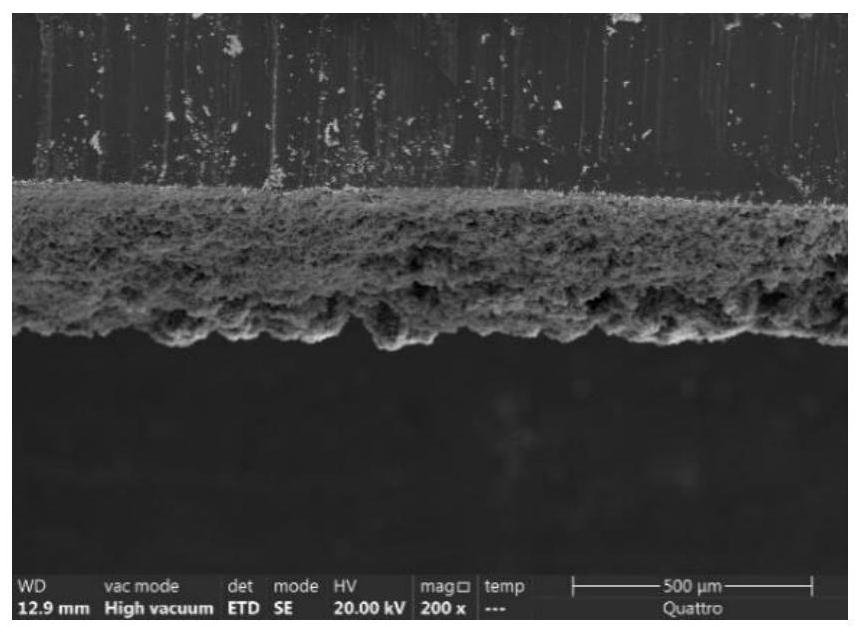

[0030] Use 400#, 100# sandpaper in turn to size 1×1cm 2 The anode and cathode red copper sheets were water-milled until the test piece was bright, and then the surface was rinsed three times with ultrapure water. 2 CO 3 After soaking in the solution at room temperature for 8 minutes, rinse off the residual lye on the surface with ultrapure water, then soak in 0.1mol / L hydrochloric acid solution for 3 minutes at room temperature, rinse off the residual acid solution on the surface with ultrapure water, and then rinse with absolute ethanol After rinsing for 3 times, blot the surface moisture with filter paper, and then use adhesive tape to insulate one side of the cathode test piece. Place the cathode and anode red copper sheets after the above pretreatment in the plating solution, and keep the distance between cathode and anode at 2 cm. The composition of the plating solution is: 0.2mol / L CuSO 4 ·5H 2 O, 1mol / L H 2 SO 4 , 15mmol / L NaCl, 15mmol / L EDTA, total surfactant con...

Embodiment 2

[0034] At 0.5mol / L Na 2 CO 3 After soaking in the solution for 10 minutes at room temperature, rinse off the residual lye on the surface with ultrapure water, and then soak in 0.5mol / L hydrochloric acid solution for 5 minutes at room temperature. The composition of the plating solution is: 0.2mol / L CuSO 4 ·5H 2 O, 1mol / LH 2 SO 4 , 15mmol / L NaCl, total surfactant content 0.6mmol / L (0.5mmol / L CTAB+0.1mmol / L M+2mg / L PEG6000). The rest of the experimental conditions and steps are consistent with Example 1.

[0035] The morphology of the microporous copper film prepared in this example is basically the same as that in Example 1 under electron microscope observation. The obtained porous copper film has a thickness of 100 μm and a porosity of 94.7%.

Embodiment 3

[0037] The cathode is copper sheet, the anode is phosphor copper sheet, at 0.8mol / L Na 2 CO 3 After soaking in the solution for 10 minutes at room temperature, rinse off the residual lye on the surface with ultrapure water, and then soak in 0.3mol / L hydrochloric acid solution for 5 minutes at room temperature. The electrodeposition time was 100s, and the rest of the experimental conditions and steps were kept the same as in Example 2.

[0038] The morphology of the microporous copper film prepared in this example is basically the same as that in Example 1 under electron microscope observation. The obtained porous copper film has a thickness of 311.4 μm and a porosity of 95.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com