Special antiviral slurry for wall cloth, wall cloth and production method of special antiviral slurry

An anti-virus and anti-viral agent technology, applied in biochemical fiber treatment, textiles and papermaking, fiber treatment, etc., can solve the problems of low continuous disinfection effect of disinfectant, large area occupied by wall covering, and adverse effects of wall covering, etc., to achieve Reduce the cost of spraying and the growth of bacteria, prevent the growth of bacteria, reduce the spread of viruses and the effect of cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

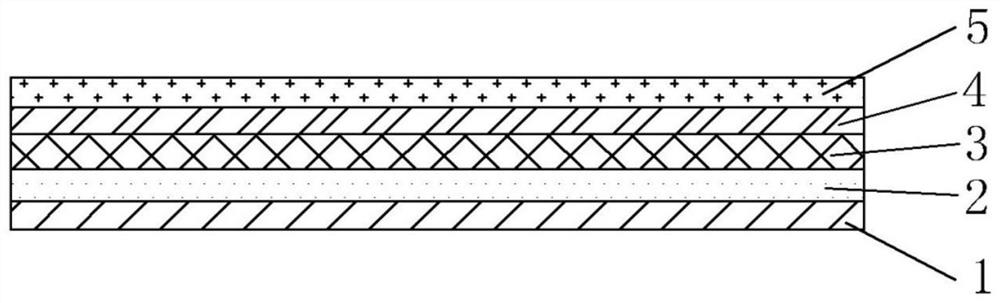

[0038] Such as figure 1 As shown, a kind of wall cloth comprises substrate layer 1, pattern layer 4 and protective layer 5 compounded in sequence, and described protective layer 5 is a waterproof antiviral coating, and described waterproof antiviral coating is made of special antiviral coating for wall covering. The slurry is coated on the pattern layer 4 and then dried.

[0039] The wall covering also includes an adhesive layer 2 and a fiber texture layer 3 that are all arranged between the base material layer 1 and the pattern layer 4, the base material layer 1, the adhesive layer 2, the fiber texture layer 3, and the pattern layer 4 Composite with protective layer 5 sequentially.

[0040] The fiber texture layer 3 is a jacquard layer; the substrate layer 1 is a non-woven layer.

[0041] The average thickness of the fiber texture layer 3 is 1 mm, the average thickness of the base material layer 1 is 0.5 mm, the average thickness of the pattern layer 4 is 0.2 mm, and the aver...

Embodiment 2

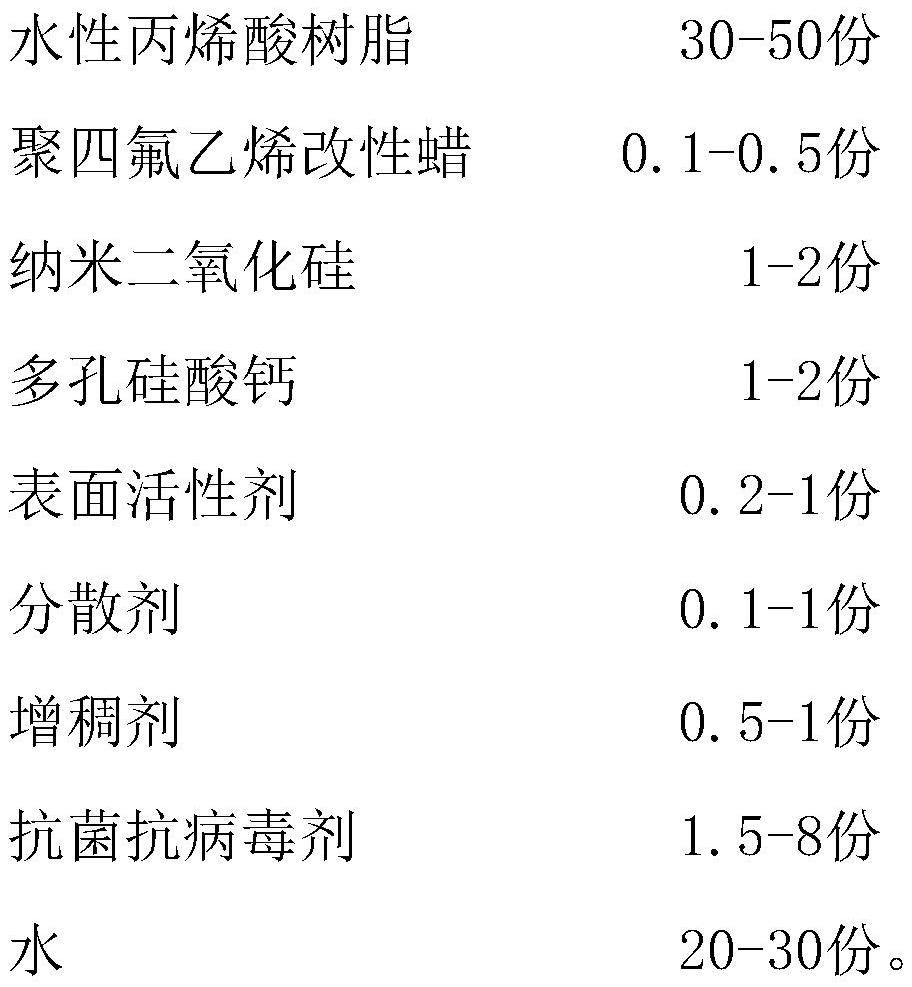

[0047] The difference between this embodiment and Embodiment 1 is that the special antiviral slurry for wall coverings includes the following raw materials in parts by weight:

[0048]

[0049] The water-based acrylic resin is ETERWAT 1161-50; the polytetrafluoroethylene modified wax is Clariant 9610F.

[0050] The antibacterial and antiviral agent is mixed with ACTICIDE MBS ICB6 and Smart Fix in a weight ratio of 1:1.

[0051] The surfactant is prepared by mixing fatty alcohol polyoxyethylene ether and cationic surfactant in a weight ratio of 1:2.

[0052] The cationic surfactant is dodecyl dimethyl benzyl ammonium chloride.

[0053] The particle diameter of the porous calcium silicate is 5 μm, and the particle diameter of the nano silicon dioxide is 50 nm.

[0054] The dispersant is DISPERBYK-190; the thickener is Acrysol RM-2020.

[0055] The preparation method of the special antiviral slurry for wall covering comprises the following steps:

[0056] (S1), water-based...

Embodiment 3

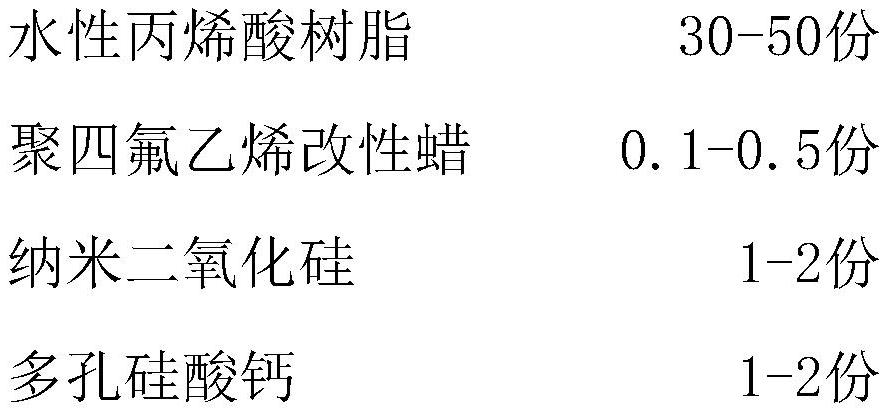

[0060] The difference between this embodiment and Embodiment 1 is that the special antiviral slurry for wall coverings includes the following raw materials in parts by weight:

[0061]

[0062] The water-based acrylic resin is ETERSOL 6923; the polytetrafluoroethylene modified wax is Clariant 9322F.

[0063] The antibacterial and antiviral agent is ACTICIDE MBS ICB6.

[0064] The surfactant is formed by mixing fatty alcohol polyoxyethylene ether and cationic surfactant in a weight ratio of 1:1.

[0065] The cationic surfactant is tetradecyltrimethylammonium chloride.

[0066] The particle diameter of the porous calcium silicate is 5 μm, and the particle diameter of the nano silicon dioxide is 50 nm.

[0067] The dispersant is DISPERBYK-199; the thickener is Acrysol RM-895.

[0068] The preparation method of the special antiviral slurry for wall covering comprises the following steps:

[0069] (S1), water-based acrylic resin, polytetrafluoroethylene modified wax, nano si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com