LAYERED PRODUCT INCLUDING ETHYLENE-alfa-OLEFIN-NON-CONJUGATED POLYENE COPOLYMER COMPOSITION LAYER AND USE THEREOF

A non-conjugated polyene and copolymer technology, applied in the field of laminates, can solve problems such as no record, and achieve the effect of excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

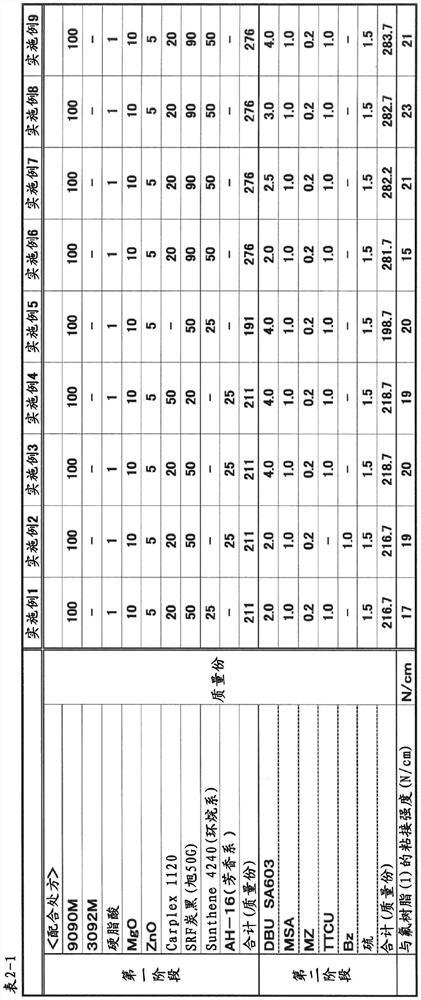

[0223] (Preparation of Copolymer Composition Containing EPDM)

[0224] As the first stage, 100 parts by mass of Mitsui EPT 9090M was masticated for 30 seconds using a BB-2 Banbury mixer (manufactured by Kobe Steel Works), and then 50 parts by mass of SRF carbon black (Asahi #50G, produced by Asahi Carbon Co., Ltd.), 20 parts by mass of basic silica (Carplex (registered trademark) 1120, produced by EVONIK Co., Ltd.), 5 parts by mass of zinc oxide (manufactured by HAKUSUI TECH Co., Ltd.), 1 part by mass stearic acid, 10 mass parts of magnesium oxide (Kyowamag 150, Kyowa Chemical Industry Co., Ltd.) and 25 mass parts of naphthenic process oil (Sunper 4240, Japan Sun Petroleum Co., Ltd.), at 140 ° C for 2 minute. Then, the upper ram was raised, cleaned, kneaded for 1 minute, and discharged at about 150° C. to obtain a first-stage complex.

[0225] Next, as the second stage, the compound obtained in the first stage was wound on an 8-inch roll (manufactured by Japan Roll Co., Ltd....

Embodiment 2~15

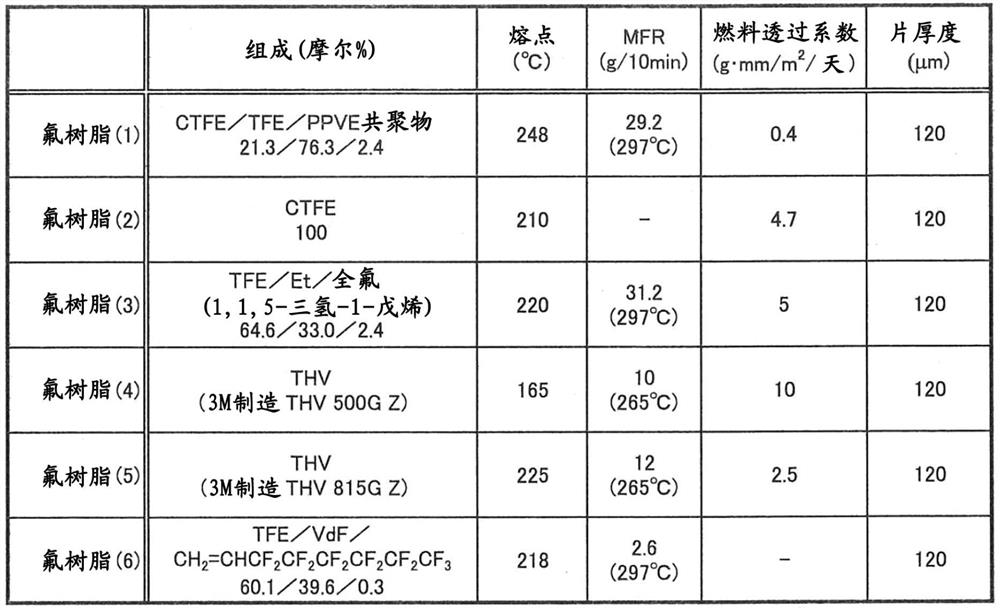

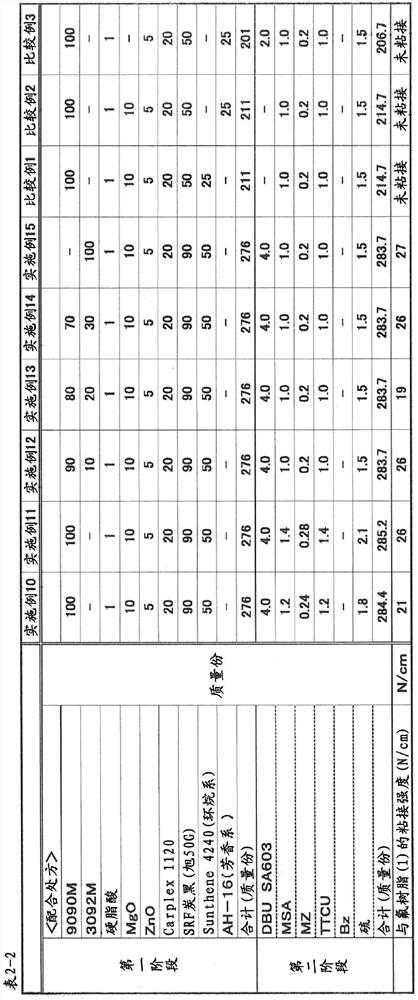

[0229] Instead of the copolymer composition used in Example 1, the compounding agents shown in Table 2, etc. were used, and after the copolymer composition was obtained by the method described in Example 1, a laminate with the fluororesin (1) was produced to obtain Bond strength.

[0230] The obtained measurement results are shown in Table 2-1 and Table 2-2.

[0231]In addition, the aromatic process oil used in Examples 2-4 is Diana process AH-16 (trade name), manufactured by Idemitsu Kosan Co., Ltd. In addition, Nocceler BZ-P (BZ) (trade name) used in Example 2 is zinc dibutyldithiocarbamate, Ouchi Shinshin Chemical Industry Co., Ltd.

Embodiment 16

[0240] Using the copolymer composition obtained in Example 4 and the fluororesins (2) to (6) listed in Table 1, respectively, a sheet of the copolymer composition having a thickness of about 3 mm and a sheet of the fluororesin having a thickness shown in Table 1 After stacking, a PTFE film (thickness: 10 μm) with a width of about 10 to 15 mm was sandwiched between two sheets at one end, and pressurized at 160° C. for 45 minutes to obtain a sheet-like laminate.

[0241] The obtained laminate was cut into strips of width 10 mm x length 40 mm x 3 sets, and the fluororesin sheet was peeled off to prepare a test piece with a grip. With regard to this test piece, using an automatic plotter (manufactured by Shimadzu Corporation AGS-J 5kN), according to the method described in JIS-K-6256 (Adhesion test method for cross-linked rubber), at 25°C with a distance of 50 mm The peeling test was carried out at a tensile speed of 1 / min, the adhesive strength was measured, and the average value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com