Cake emulsifier with dense and fine texture and preparation method thereof

A cake emulsifier, delicate technology, applied in baking, dough processing, food science and other directions, can solve problems such as overall application performance to be improved, affecting cake taste, easy defoaming of egg batter, etc., to ensure preservation stability , The effect of reducing the loss of bubbles and increasing the amount of binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

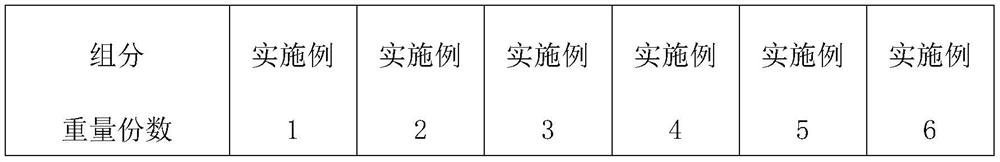

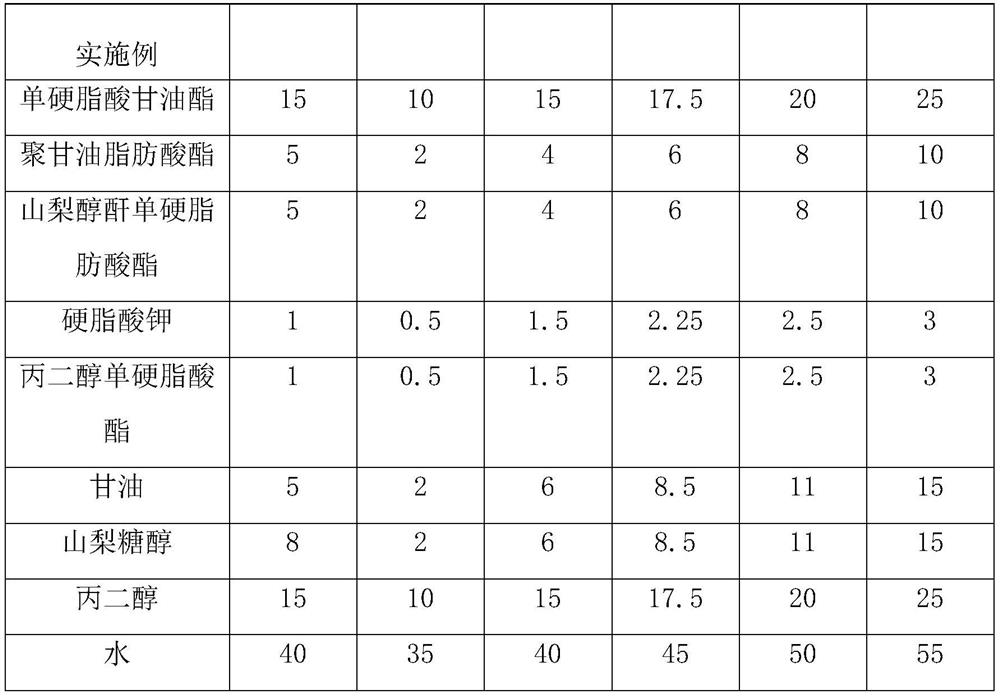

[0051] A dense and fine-textured cake emulsifier, its components and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0052] (1) Prepared according to the proportion containing glyceryl monostearate, polyglycerol fatty acid ester, sorbitan monostearate, potassium stearate, propylene glycol monostearate, glycerin, sorbitol, propylene glycol and water raw materials;

[0053] (2) Stir and mix the raw materials in step (1), at a stirring speed of 100rpm, stir at room temperature for 3h; heat up to 90°C, stir for 30min; then cool down to 75°C, keep stirring for 2.5h, and finally cool and fill to obtain the final product.

Embodiment 2

[0055] A dense and delicate type cake emulsifier, different from Example 1 in that it is prepared through the following steps:

[0056] (1) Prepared according to the proportion containing glyceryl monostearate, polyglycerol fatty acid ester, sorbitan monostearate, potassium stearate, propylene glycol monostearate, glycerin, sorbitol, propylene glycol and water raw materials;

[0057] (2) Stir and mix the raw materials in step (1) at a stirring speed of 100rpm, stir at room temperature for 2.5h; heat up to 95°C, stir for 20min; then cool down to 80°C, keep stirring for 2h, and finally cool and fill to obtain the final product.

Embodiment 3

[0059] A dense and delicate type cake emulsifier, different from Example 1 in that it is prepared through the following steps:

[0060] (1) Prepared according to the proportion containing glyceryl monostearate, polyglycerol fatty acid ester, sorbitan monostearate, potassium stearate, propylene glycol monostearate, glycerin, sorbitol, propylene glycol and water raw materials;

[0061] (2) Stir and mix the raw materials in step (1), at a stirring speed of 100rpm, stir at room temperature for 3.5h; heat up to 85°C, stir for 40min; then cool down to 70°C, keep stirring for 3h, and finally cool and fill to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com