Longan pulp superfine powder and preparation method thereof

A technology of ultra-fine powder and longan meat, which is applied in food science, food drying, food mechanical processing, etc. It can solve the problems of high sugar viscosity, natural material flavor and nutritional changes, etc., and achieve low loss of polysaccharides, reduce viscosity, and increase solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

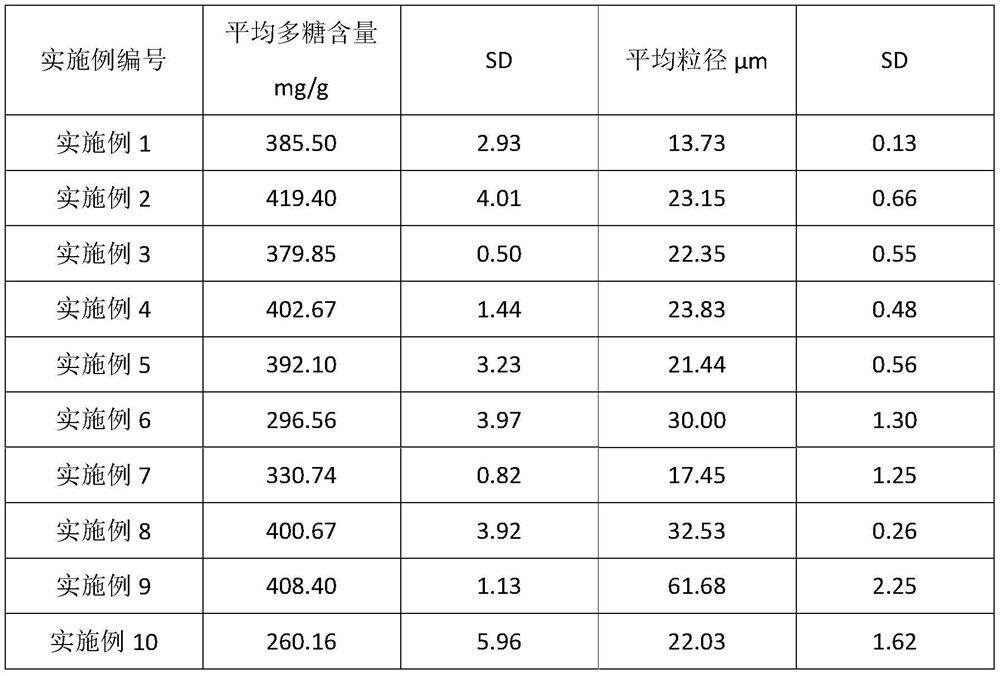

Examples

preparation example Construction

[0028] In order to solve the above problems, the present invention provides a method for preparing longan meat superfine powder, comprising the following steps:

[0029] S1: Take the longan pulp and soak it in edible ethanol according to the ratio of material to liquid for pretreatment;

[0030] S2: After soaking, wash the pulp surface with distilled water, put it into a beater for beating, and obtain longan pulp homogenization;

[0031] S3: putting the obtained longan pulp homogenate into an oven for drying, and then softening at room temperature to obtain a dried pulp homogenate;

[0032] S4: pulverize the dried pulp homogenate with a universal grinder to obtain longan pulp coarse powder;

[0033] S5: Superfinely pulverize the longan pulp coarse powder described in step S4 to obtain longan pulp superfine powder.

[0034] Because the longan pulp contains many alcohol-soluble impurities, such as pigments and oligosaccharides, in addition to polysaccharides, therefore, in the...

Embodiment 1

[0052] A preparation method of longan meat superfine powder, comprising the following steps:

[0053] S1: Take 300g longan, remove the longan shell and longan core, soak in edible ethanol with a mass concentration of 80% for 36 hours according to the ratio of solid to liquid 1:3, and change the liquid every 12 hours;

[0054] S2: After soaking, wash the pulp surface with distilled water, put it into a beater for beating, and obtain longan pulp homogenization;

[0055] S3: Put the obtained longan pulp homogenate into an oven at 50°C for 24 hours, and then place it at room temperature to soften for 24 hours to obtain a dried pulp homogenate;

[0056] S4: The dried pulp homogenate is pulverized for 3 minutes with a universal grinder to obtain longan pulp coarse powder;

[0057] S5: Superfinely pulverize the longan pulp coarse powder described in step S4 at -15° C. for 5 minutes to obtain longan pulp superfine powder.

Embodiment 2

[0059] A preparation method of longan meat superfine powder, comprising the following steps:

[0060] S1: Take 300g longan, remove the longan shell and longan core, soak in edible ethanol with a mass concentration of 80% for 36 hours according to the ratio of solid to liquid 1:2, and change the liquid every 12 hours;

[0061] S2: After soaking, wash the pulp surface with distilled water, put it into a beater for beating, and obtain longan pulp homogenization;

[0062] S3: Put the obtained longan pulp homogenate into an oven at 50°C for 24 hours, and then place it at room temperature to soften for 24 hours to obtain a dried pulp homogenate;

[0063] S4: The dried pulp homogenate is pulverized for 3 minutes with a universal grinder to obtain longan pulp coarse powder;

[0064] S5: Superfinely pulverize the longan pulp coarse powder described in step S4 at -15° C. for 5 minutes to obtain longan pulp superfine powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com