Preparation method and application of a photocatalytic sewage treatment membrane

A technology for sewage treatment and photocatalysis, which is applied in the fields of illumination water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. It can solve the problem that the catalytic activity cannot meet the large-scale application and achieve excellent Effects of membrane flux, accelerated transfer, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

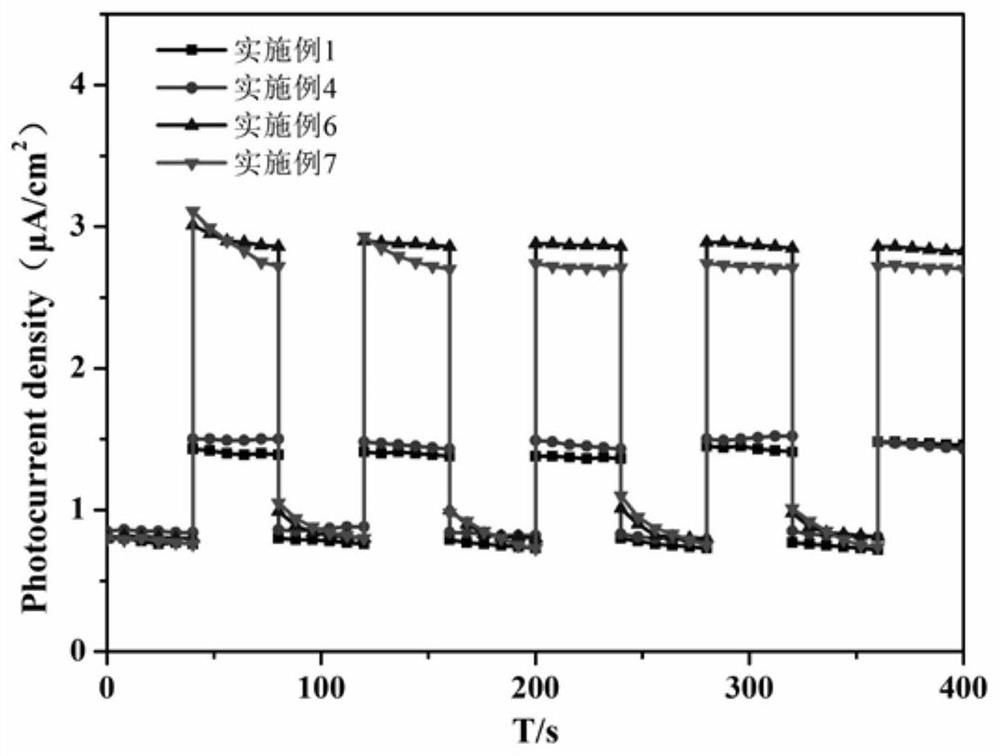

Examples

Embodiment 1

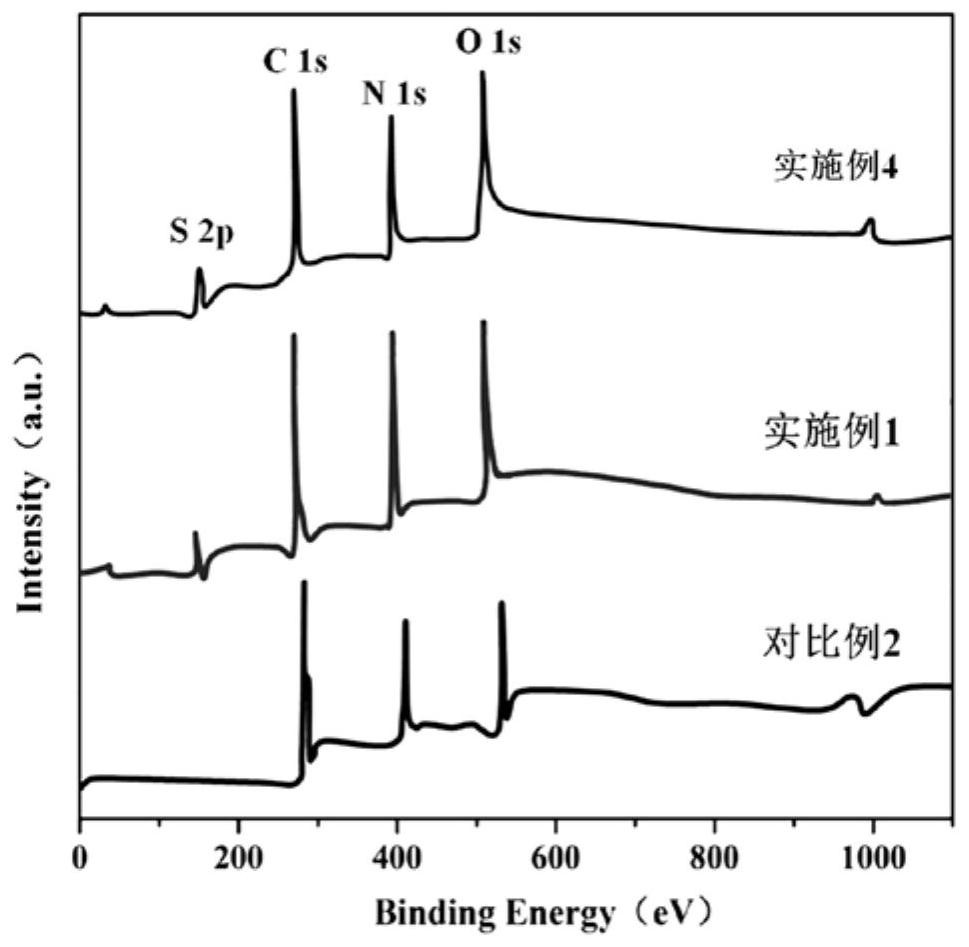

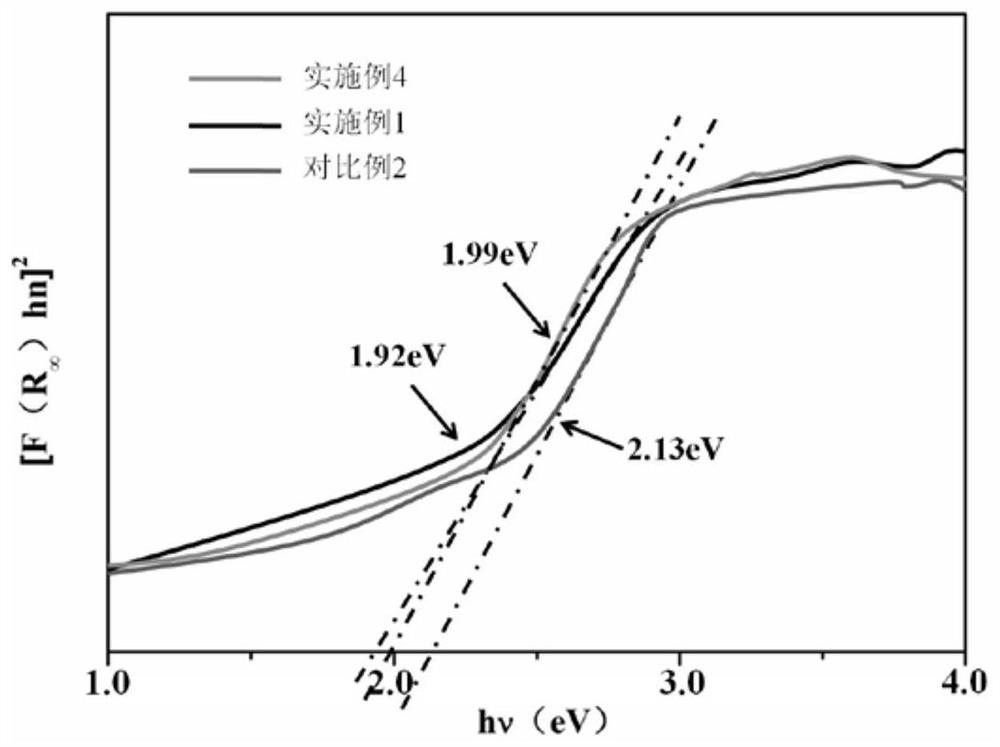

[0029] Preparation of photocatalytic materials:

[0030] Weigh 500mg of g-C 3 N 4 Add to a 250mL beaker containing 100mL deionized water to form a suspension and ultrasonically disperse for 30min; add dopamine hydrochloride (dopamine hydrochloride and g-C 3 N 4 The mass ratio of dopamine hydrochloride to 8-mercaptoguanosine is 1:11.5), and magnetically stirred at room temperature for 60min to make it evenly mixed; The solid-to-liquid ratio of 8-mercaptoguanosine to Tris-HCl buffer solution was 1 g:2.5 mL), and the pH was adjusted to 8.5 with 1 M NaOH solution, and the reaction was performed under magnetic stirring at 60° C. for 24 h. The reacted suspended sample was cooled to room temperature, centrifuged for 10 min (4000 r / min) in a centrifuge, and then the solid sample was collected and washed with deionized water for 3 times, and baked at 60° C. for 12 h to obtain the photocatalytic material.

[0031] Preparation of a photocatalytic sewage treatment membrane:

[0032] ...

Embodiment 2

[0034] The difference between the preparation of photocatalytic material and embodiment 1 is: dopamine hydrochloride and g-C 3 N 4 The mass ratio of dopamine hydrochloride to 8-mercaptoguanosine is 1:1; the solid-liquid ratio of 8-mercaptoguanosine to Tris-HCl buffer solution is 1g:2mL; g-C 3 N 4 The concentration of the suspension was 4.5 mg / mL.

[0035] The preparation of a photocatalytic sewage treatment membrane is the same as in Example 1.

Embodiment 3

[0037] The difference between the preparation of photocatalytic material and embodiment 1 is: dopamine hydrochloride and g-C 3 N 4 The mass ratio of dopamine hydrochloride to 8-mercaptoguanosine is 1:1.4; the solid-liquid ratio of 8-mercaptoguanosine to Tris-HCl buffer solution is 1g:3mL; g-C 3 N 4 The concentration of the suspension was 5.4 mg / mL.

[0038] The preparation of a photocatalytic sewage treatment membrane is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com