Method for preparing biochar from tea residues

A technology of biochar and tea dregs, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of waste of resources, increase costs, etc., and achieve strong adsorption effect, increased adsorption capacity, and obvious adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Preparation and characterization of tea residue biochar

[0058] Tea leaves are used as raw materials for preparing biochar, crushed by a pulverizer, passed through a 60-mesh sieve, and dried in an oven. The dried tea residue was pyrolyzed for 120min at 500°C and N2 conditions of a tube furnace, and after cooling ( figure 1 ) to grind biochar.

[0059]Mix the above biochar material with saturated KOH solution (alkali-carbon ratio 1.5:1) for 9 hours, dry and cool, then grind. Pyrolyze at 700°C under N2 for 120min, take it out, grind it, wash it repeatedly with water and 0.1mol / L hydrochloric acid until it is nearly neutral, and dry to obtain the activated biochar material ( figure 1 ), stored in a desiccator for later use.

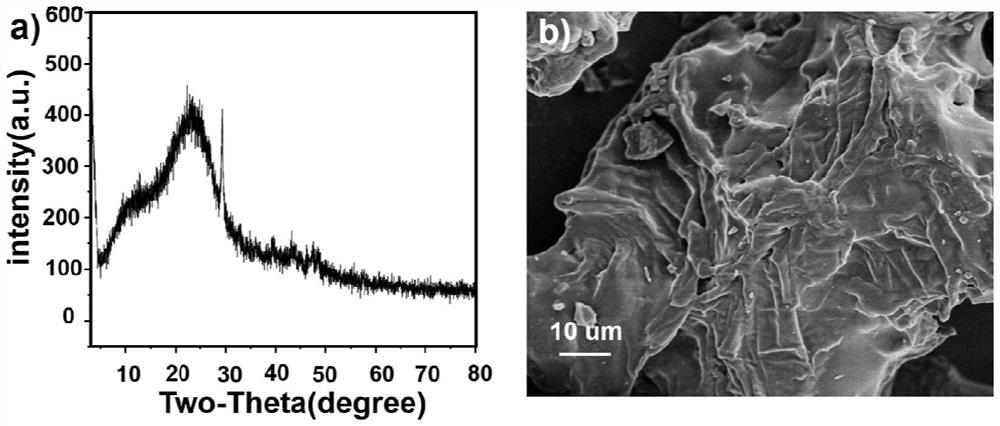

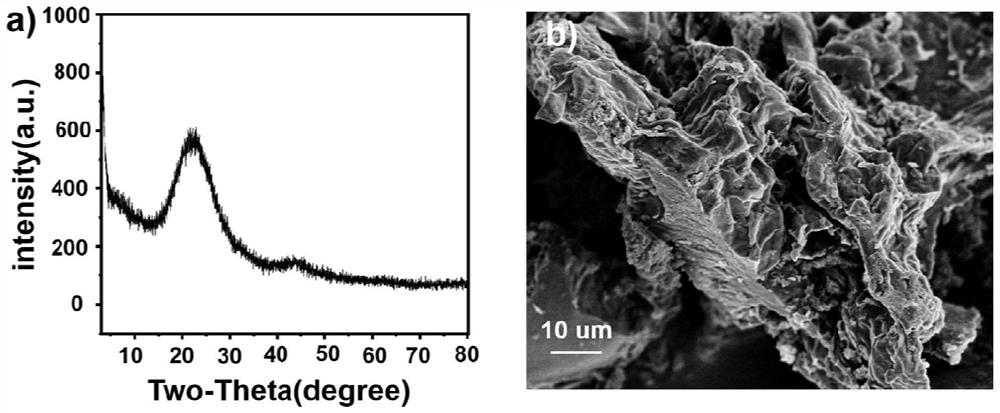

[0060] The crystal form of the activated biochar was characterized by X-ray powder diffraction, the BET specific surface area was measured, and its morphology was observed by SEM. The results showed that the prepared activated biochar ...

Embodiment 2

[0061] Example 2, the adsorption experiment of tea dregs biochar to bispyribac

[0062] Prepare bispyribac ether solutions with different concentrations, measure the absorbance at 247nm with a UV spectrophotometer, and make a standard curve.

[0063] Two parts of 100mg / L bispyribac ether solution were prepared for use. Weigh 0.015g activated biochar and unactivated biochar and add to the above solution, another solution without biochar is placed in a magnetic stirrer for reaction, and the reaction temperature is 25°C. Take samples at different time intervals, place them in a high-speed centrifuge at room temperature and centrifuge at 6000r / min for 15min, take out the supernatant solution and filter it with a 0.22μm aqueous phase needle, measure its absorbance with a UV spectrophotometer, repeat three times for each group, Take the average value and substitute it into the standard curve to calculate the concentration.

[0064] After measurement, it was found that the removal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com