Spherical catalyst carrier containing molecular sieve and alumina and its preparation and application

A catalyst carrier, molecular sieve technology, applied in molecular sieve catalysts, catalyst carriers, physical/chemical process catalysts, etc., can solve problems such as gaps, and achieve the effects of good spherical sphericity, colloidal stability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

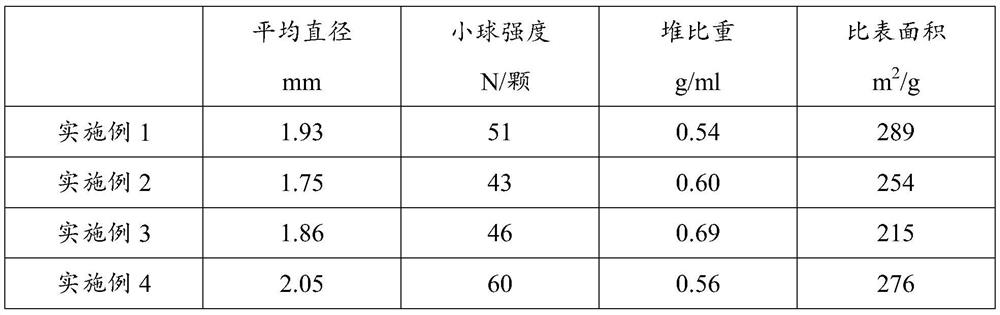

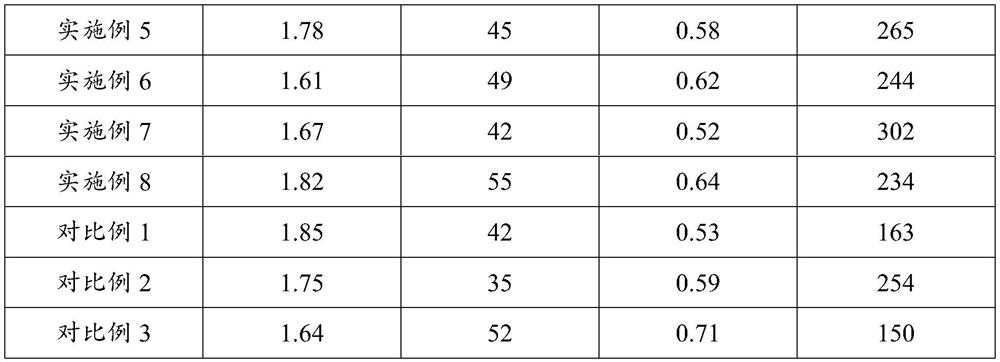

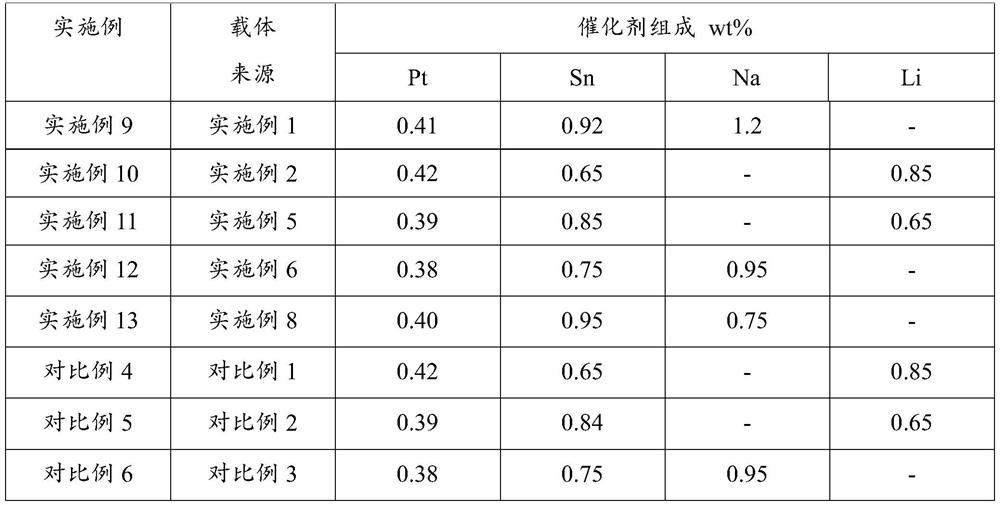

Examples

Embodiment 1

[0029] The preparation process of the spherical catalyst carrier containing molecular sieve and alumina in this embodiment is as follows:

[0030] 1. Dissolve 375g of aluminum nitrate in 500g of deionized water at 60°C, add 7% ammonia solution under airtight conditions until the pH value is between 7 and 8, and then wash under pressure filter conditions until the filtrate is neutral. Wet filter cake: add deionized water to the wet filter cake and stir evenly, add nitric acid solution with a concentration of 50% for peptization, control the pH value of the sol at 4.0, and finally the solid content of the sol is 35%;

[0031] 2. Mix 100g of macroporous pseudo-boehmite and 60g of ZSM-5 (silicon-aluminum ratio 200) molecular sieve, add deionized water and carry out ball milling, the total solids of pseudo-boehmite and molecular sieve in the suspension after ball milling The content is 50%, and the particle D90 in the suspension after ball milling is 30nm.

[0032] 3. Add the susp...

Embodiment 2

[0036] The preparation process of the spherical catalyst carrier containing molecular sieve and alumina in this embodiment is as follows:

[0037] 1. Dissolve 270g of aluminum nitrate in 500g of deionized water at 80°C, add 7% ammonia solution under airtight conditions until the pH value is between 7 and 8, and then wash under pressure filter conditions until the filtrate is neutral. Wet filter cake: add deionized water to the wet filter cake and stir evenly, add nitric acid solution with a concentration of 30% for peptization, control the pH value of the sol at 3.5, and finally the solid content of the sol is 25%;

[0038]2. After mixing 80g of macroporous pseudo-boehmite and 70g of ZSM-5 (silicon-aluminum ratio 100) molecular sieve, add deionized water and carry out ball milling, so that the total amount of pseudo-boehmite and molecular sieve in the suspension after ball milling is The solid content is 35%, and the particle D90 in the suspension after ball milling is 25nm. ...

Embodiment 3

[0043] The preparation process of the spherical catalyst carrier containing molecular sieve and alumina in this embodiment is as follows:

[0044] 1. Dissolve 150g of anhydrous aluminum chloride in 650g of deionized water at 50°C, add 10% ammonia solution under airtight conditions until the pH value is between 7 and 8, and then wash under pressure filter conditions until the filtrate is neutral to obtain a wet filter cake; add deionized water to the wet filter cake and stir evenly, add nitric acid solution with a concentration of 40% for peptization, control the pH value of the sol at 3.0, and finally the solid content of the sol is 28%;

[0045] 2. After mixing 150g of macroporous pseudo-boehmite and 80g of SPAO-34 (silicon-aluminum ratio 0.4) molecular sieve, add deionized water and carry out ball milling, so that the total amount of pseudo-boehmite and molecular sieve in the suspension after ball milling The solid content is 40%, and the particle D90 in the suspension after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com