Large-scale wind power bearing ring machining method adopting composite cutting, and tool

A processing method and technology of bearing rings, which are applied to lathe tools, manufacturing tools, metal processing equipment, etc., can solve the problems of "fish scales, defects, obvious vibration of hand-held tool table, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

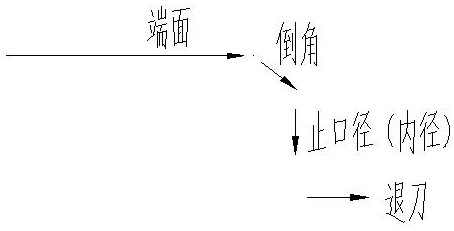

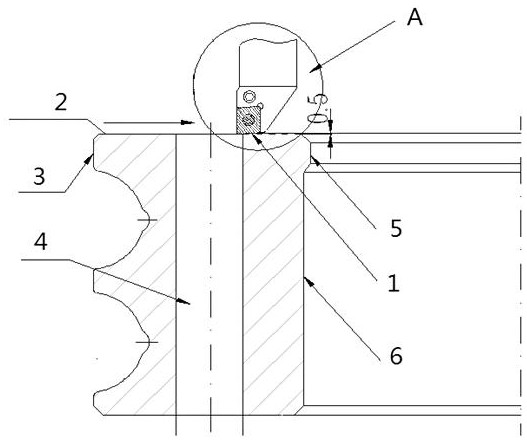

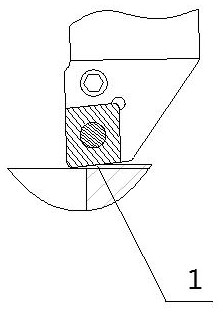

[0042] Such as Figure 1-3 As shown, the processing method of large-scale wind power bearing rings using compound cutting takes the inner ring as an example; it includes forward cutting and reverse cutting, and the specific processing steps are as follows: The cutting path: end face - chamfering - stop diameter - retraction processing is completed;

[0043] The processing direction of the end face is from the outer diameter of the ferrule to the direction of the inner diameter 6, and the stop diameter 5 refers to the direction where the inner diameter 6 of the ferrule is located;

[0044] The caliber 5 adopts forward cutting, that is, the cutting of the tip of the knife; the end face and chamfering adopt reverse cutting, that is, the auxiliary cutting edge is in contact with the surface of the workpiece to participate in cutting;

[0045] Further, in the end face cutting process in the cutting path from the end face of the ferrule to the inner diameter 6 direction, the starti...

Embodiment 2

[0052] In the implementation of 1, the inner ring is used as an example processing method, including forward cutting and reverse cutting, and the specific processing sequence steps are as follows:

[0053] The cutting path from the end face of the ferrule to the outer diameter direction: end face—chamfer—leading diameter—retraction processing is completed;

[0054] The processing direction of the end face is from the inner diameter of the ferrule to the outer diameter direction, and the guide diameter is the direction where the outer diameter of the ferrule is located;

[0055] Further, the guide diameter 3 adopts forward cutting, that is, part of the cutting edge; the end face and chamfering adopt reverse cutting, that is, the auxiliary cutting edge contacts with the surface of the workpiece to participate in cutting; the internal cutting edge in this embodiment The tool used in the ring machining method is the same as that used in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com