A kind of steel slag sand production process and system

A production process and technology of steel slag sand, applied in the field of steel slag sand, can solve the problems of large expansion rate of steel slag sand, application limitations, concrete stability defects, etc., and achieve the effects of small capital investment, low operating cost, and elimination of stability defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below with reference to the accompanying drawings and through specific embodiments.

[0054] After joint research by the inventor unit and the university team, it was found that the main reason for the large expansion rate of traditional steel slag sand and easy to cause poor volume of concrete is that: as the steelmaking technology matures, the smelting time is gradually shortened, resulting in the inability of calcium oxide and magnesium oxide to mix with each other. Components such as silica react sufficiently to form free calcium oxide (f-CaO) and magnesium oxide (f-MgO), and these free calcium oxide (f-CaO) and magnesium oxide (f-MgO) are the The main reason for the large expansion rate of steel slag sand and the defect of concrete stability.

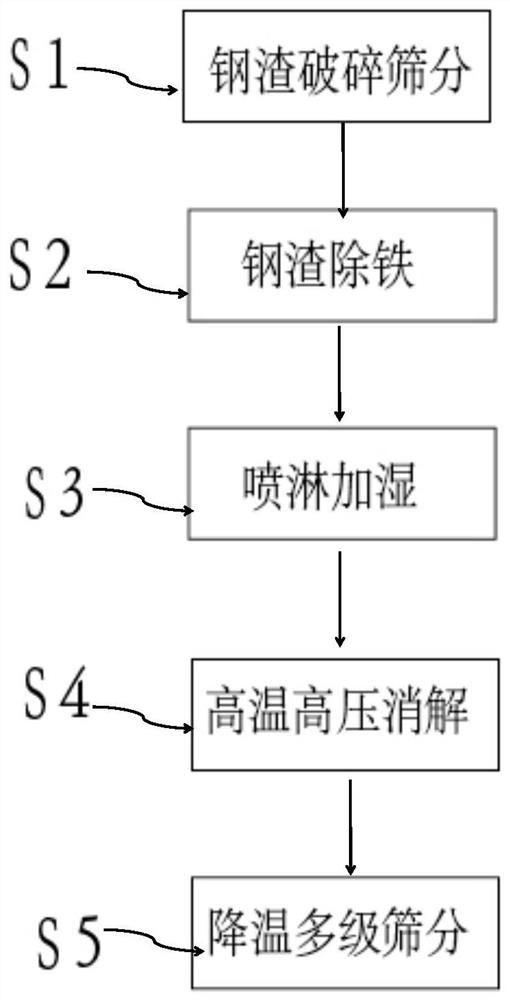

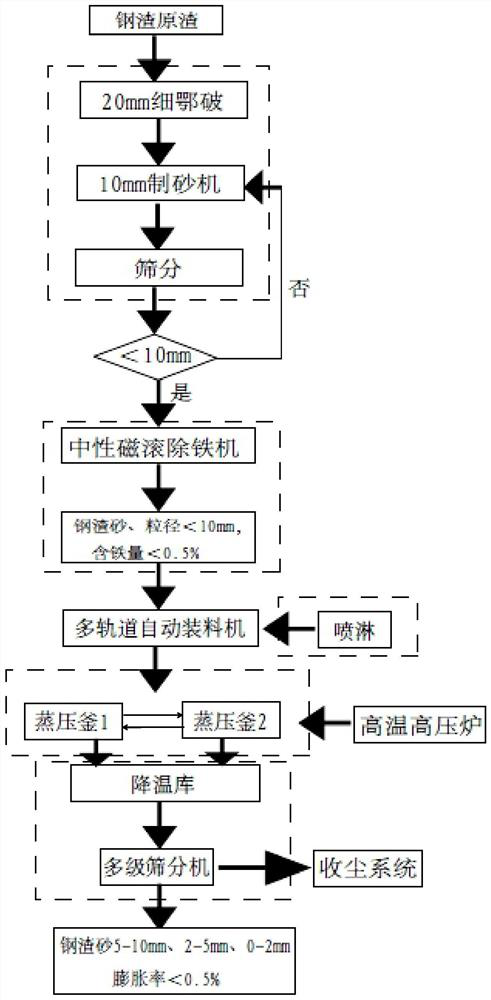

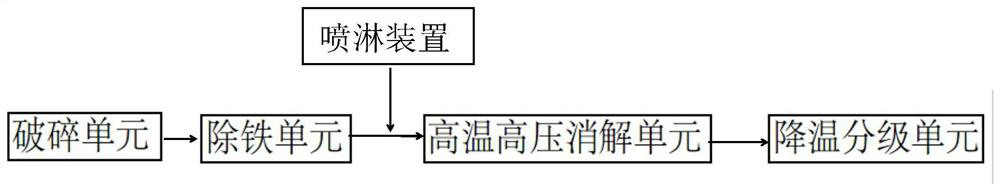

[0055] Through crushing, screening, iron removal, spraying, and high temperature and high press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic force | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com