Microwave dielectric ceramic, preparation method thereof and microwave device

A technology for microwave dielectric ceramics and conditions, applied in the field of ceramic materials, can solve the problems of poor uniformity, consistency and dielectric properties, low qualification rate of microwave dielectric ceramics, complex processing procedures, etc., and achieve good uniformity and consistency. , excellent dielectric properties, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The microwave dielectric ceramic of the present disclosure is prepared by the following method:

[0061] (1) Place the microwave dielectric ceramic granules in an injection molding machine for injection molding to obtain a microwave dielectric ceramic green body, wherein the injection molding conditions include: the mold temperature is 140°C, and the pressure holding speed is 30mm / s , the injection temperature is 180°C, the injection pressure is 120MPa, and the injection speed is 50mm / s;

[0062] Wherein, the microwave dielectric ceramic granules used in this embodiment are composed of microwave dielectric ceramic powder and a binder composition. Based on the microwave dielectric ceramic granules, the amount of microwave dielectric ceramic powder is 80% by weight. The amount of the binder composition is 20% by weight, the average particle size of the microwave dielectric ceramic particles is 3.3 μm, and the melt index under the condition of 190°C / 2.16kg is 40 cm 3 / 10m...

Embodiment 2

[0071] Microwave dielectric ceramics were prepared according to the method in Example 1, except that the melt index of the microwave dielectric ceramic pellets used in this example was 15 cm under the condition of 190 °C / 2.16 kg 3 / 10min; wherein, in the microwave dielectric ceramic granules, the particle size D50 of the microwave dielectric ceramic powder is 3.4 μm, the particle size D90 is 7.2 μm, and the particle size D10 is 1.2 μm; The melt index is 180 g / 10min, the weight average molecular weight is 20000 g / mol, the crystallinity is 65%, the tensile strength is 40 MPa, and the elongation at break is 3%;

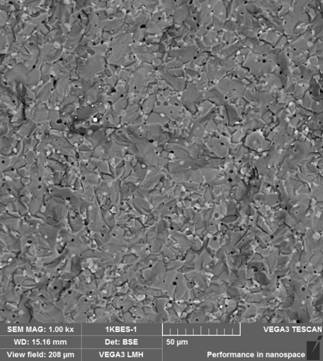

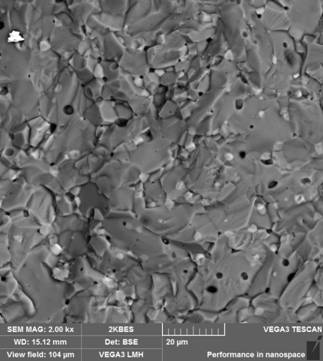

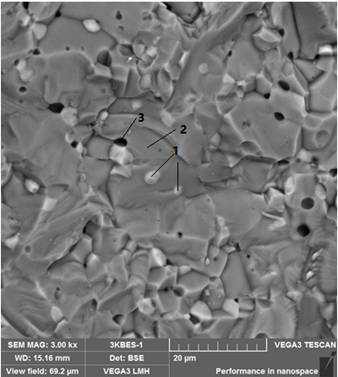

[0072] The microstructure of the microwave dielectric ceramics prepared in this example was observed by scanning electron microscopy, and the results showed that the microwave dielectric ceramics contained MgTiO 3 Grains and CaTiO 3 grains, the CaTiO 3 grain embedded distribution in the MgTiO 3 between the grains, where the CaTiO 3 CaTiO with a grain size D50 of 2.5 ...

Embodiment 3

[0075] Prepare microwave dielectric ceramics according to the method of Example 1, the difference is: the melting index of the microwave dielectric ceramic pellets used in this example is 25cm under the condition of 190°C / 2.16kg 3 / 10min; wherein, in the microwave dielectric ceramic granules, the particle size D50 of the microwave dielectric ceramic powder is 3.5 μm, the particle size D90 is 7.0 μm, and the particle size D10 is 1.0 μm; The melt index is 220 g / 10min, the weight average molecular weight is 70000 g / mol, the crystallinity is 70%, the tensile strength is 60 MPa, and the elongation at break is 8%;

[0076] The microstructure of the microwave dielectric ceramics prepared in this example was observed by scanning electron microscopy, and the results showed that the microwave dielectric ceramics contained MgTiO 3 Grains and CaTiO 3 grains, the CaTiO 3 grain embedded distribution in the MgTiO 3 between the grains, where the CaTiO 3 CaTiO with a grain size D50 of 3.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com