Nanocrystalline A4B2O9 type tantalate ceramic prepared through ultralow-temperature sintering and method thereof

A technology of A4B2O9 and tantalate is applied in the field of ultra-low temperature sintering to prepare nanocrystalline A4B2O9 type tantalate ceramics, which can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

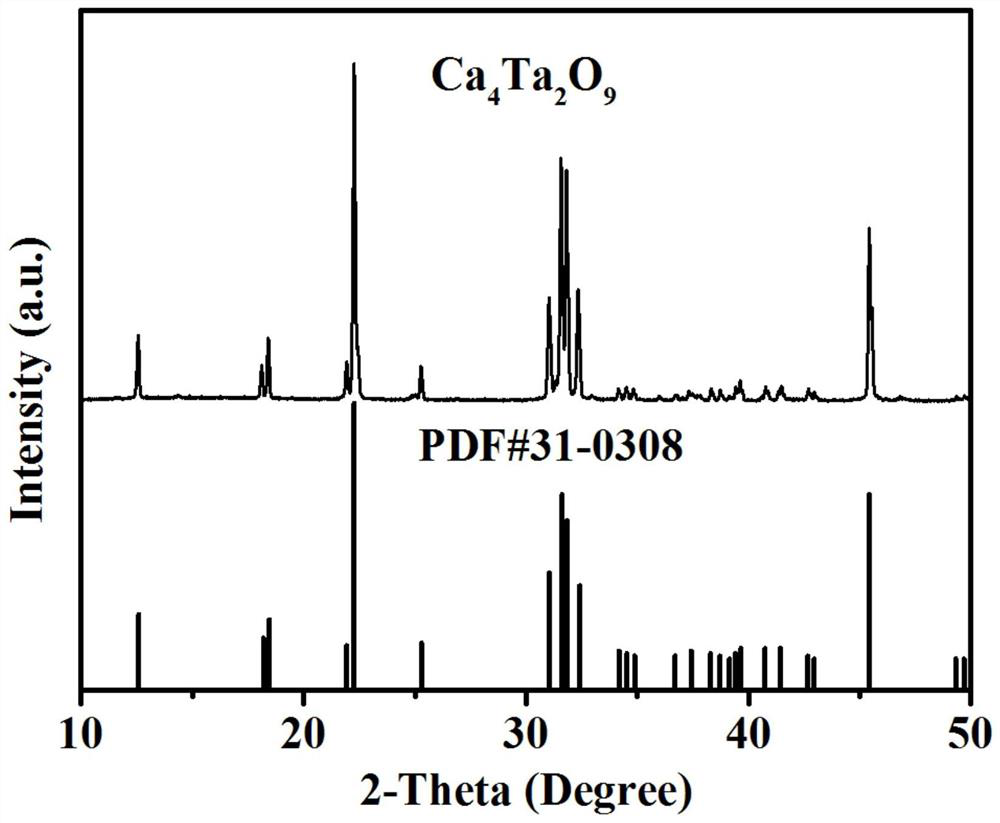

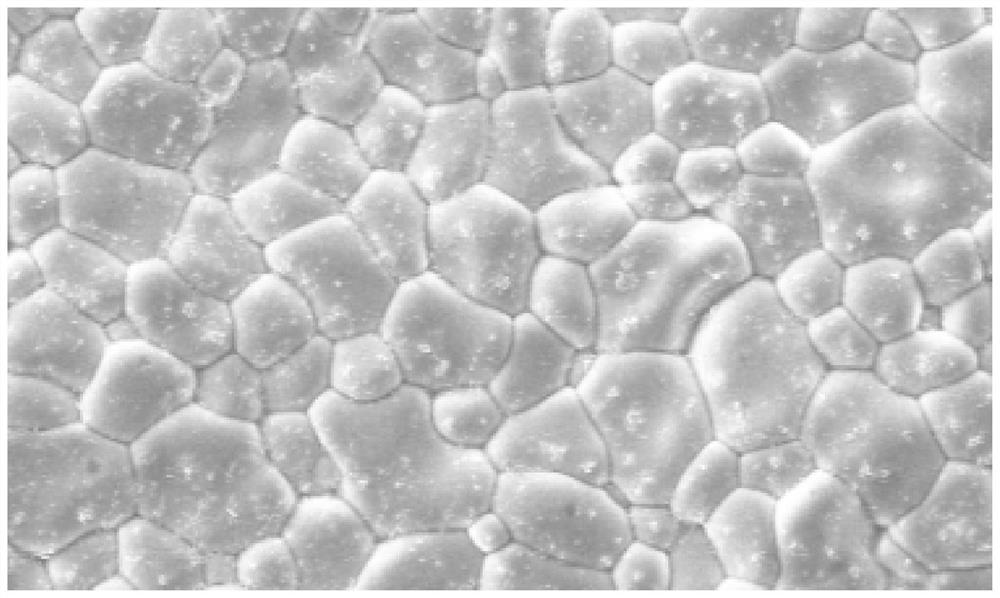

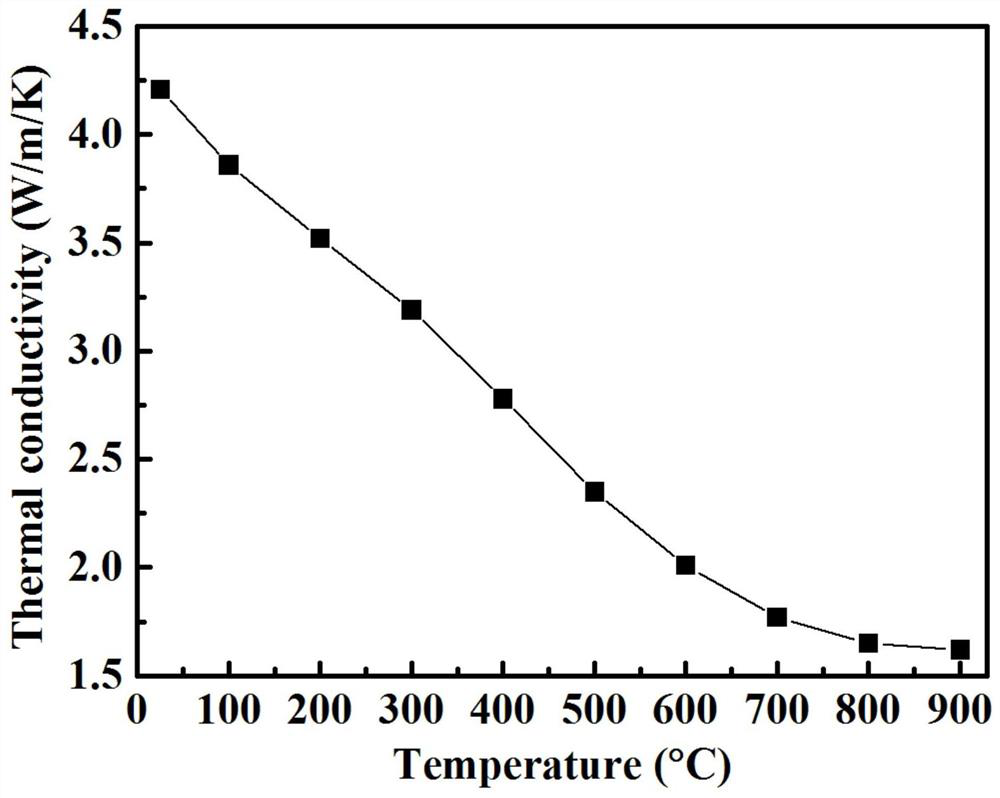

[0036] A nanocrystalline A4B2O9 type tantalate ceramic prepared by ultra-low temperature sintering, the structural formula of the ceramic is Ca 4 Ta 2 o 9 , its preparation method comprises the following steps:

[0037] step one,

[0038] Ca(OH) 2 , CaCO 3 and Tan oxalate were kept at 350-900°C for 1-2h respectively. During the heat preservation process, the raw materials were thermally decomposed to obtain highly reactive CaO and Ta 2 o 5 powder. In this embodiment, the heat preservation temperature is preferably 900° C., and the heat preservation time is preferably 1 h.

[0039] step two,

[0040] According to Ca 4 Ta 2 o 9 The structural formula weighs highly reactive CaO and Ta 2 o 5 powder, and will highly reactive CaO and Ta 2 o 5 Put the powder into the high-energy ball mill, and then put alcohol with a concentration of 99.99% into the high-energy ball mill. The weight ratio of powder to alcohol is 1:6-10, and the CaO and Ta 2 o 5 The powder is ground, ...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is that the structural formula of the A4B2O9 type tantalate ceramics in this embodiment is Ni 4 Ta 2 o 9 , its preparation method is consistent with Example 1.

Embodiment 3

[0046] The difference between embodiment 3 and embodiment 1 is that the structural formula of the A4B2O9 type tantalate ceramics in this embodiment is Co 4 Ta 2 o 9 , its preparation method is consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com