A kind of ultramicroporous hydrophobic uio-66 zirconium metal organic framework material and its preparation method and application

A metal-organic framework and uio-66 technology, applied in chemical instruments and methods, other chemical processes, products, etc., can solve the problems of poor adsorption and separation performance and poor hydrophobicity, and achieve strong adsorption and separation capabilities and high temperature resistance , the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

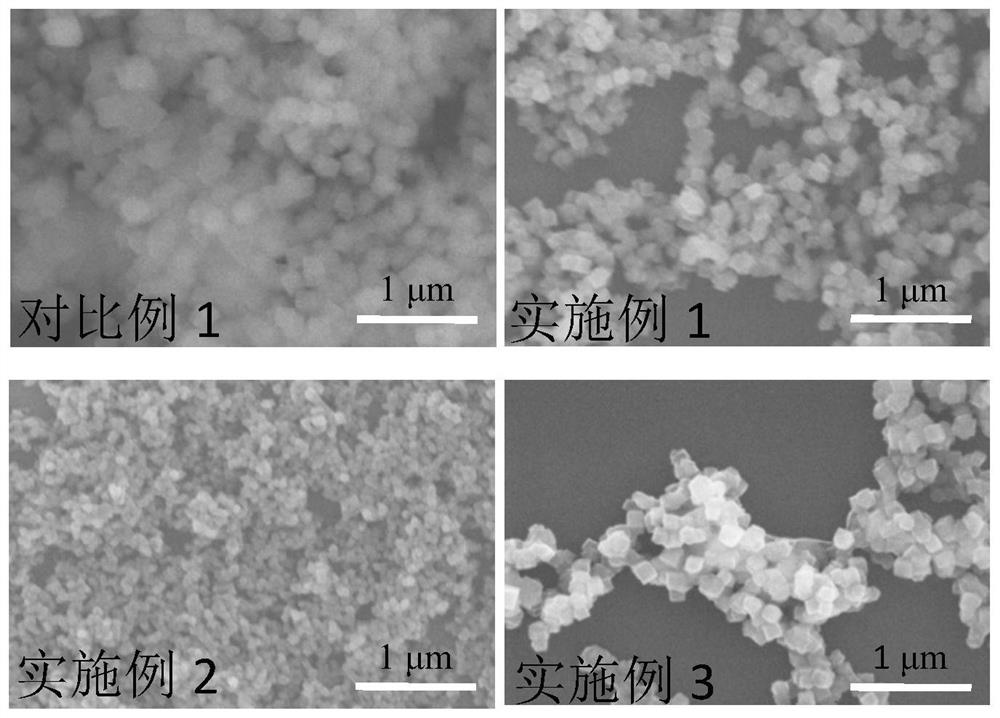

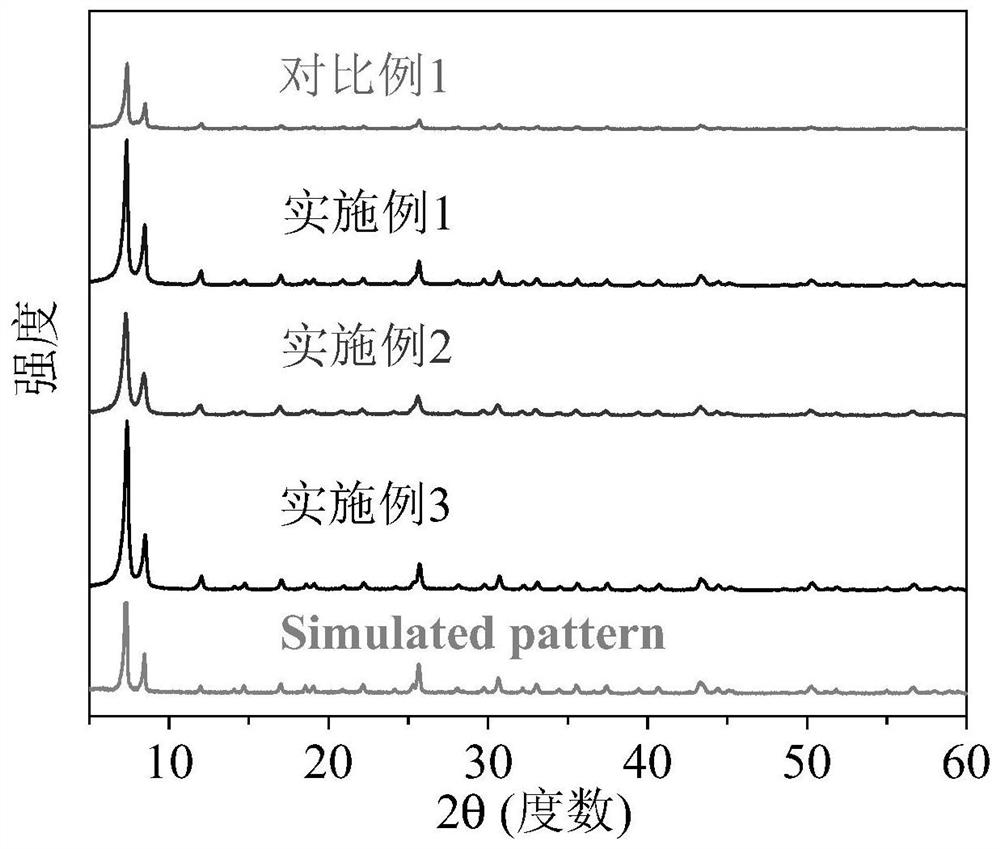

[0035] An ultra-microporous hydrophobic UiO-66 zirconium metal-organic frame material prepared by coordination of trifluoromethylbenzoic acid with terephthalic acid and zirconium ions.

[0036] The preparation method of the ultraporous hydrophobic UiO-66 zirconium metal-organic framework material described above, comprising the following steps:

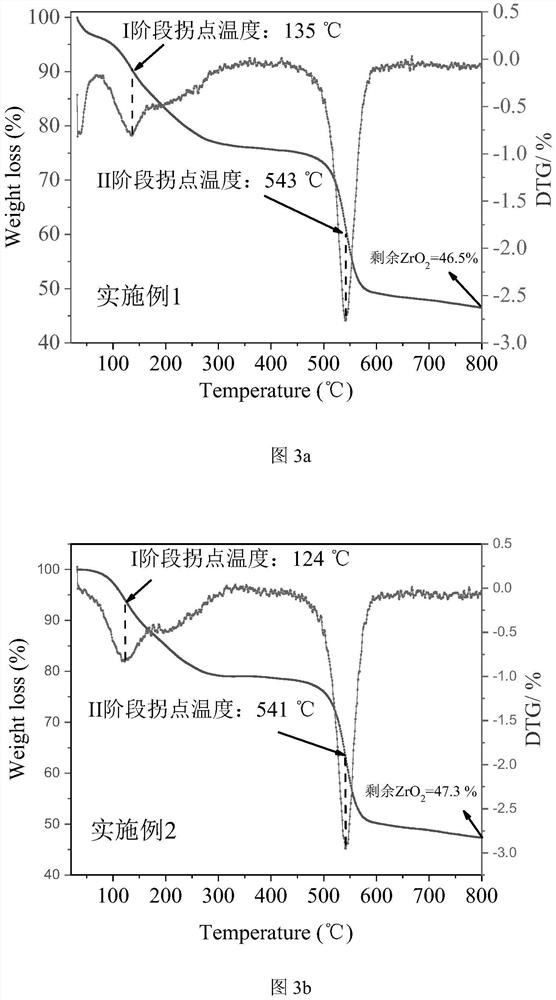

[0037]0.23g zirconium tetrachloride and 0.019g 2-trifluoromethylbenzoic acid were added to 60ml DMF and stirred for 2h for premixing, and then added 0.17g of terephthalic acid to the mixed liquid, stirred and dissolved for 10 min at a stirrer rotation of 300 revolutions, the resulting mixed solution was moved to a stainless steel high-pressure reactor made of PTFE, at a speed of 1.0 °C / min from room temperature to 120 °C, maintained at 120 °C for 20h, After the end of the reaction, the extract collected was washed with DMF, ethanol for 3 to 4 times, centrifuged at 8000r / min rotational speed for 3min, and the lower layer product was dried ...

Embodiment 2

[0039] An ultra-microporous hydrophobic UiO-66 zirconium metal-organic frame material prepared by coordination of trifluoromethylbenzoic acid with terephthalic acid and zirconium ions.

[0040] The above-described ultraporous hydrophobic UiO-66 zirconium metal-organic framework material is prepared in the same way as In Example 1, the difference is that 2-trifluoromethylbenzoic acid is replaced with 3-trifluoromethylbenzoic acid.

Embodiment 3

[0042] An ultra-microporous hydrophobic UiO-66 zirconium metal-organic frame material prepared by coordination of trifluoromethylbenzoic acid with terephthalic acid and zirconium ions.

[0043] The above-described ultraporous hydrophobic UiO-66 zirconium metal-organic framework material is prepared in the same way as In Example 1, the difference is that 2-trifluoromethylbenzoic acid is replaced with 4-trifluoromethylbenzoic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com