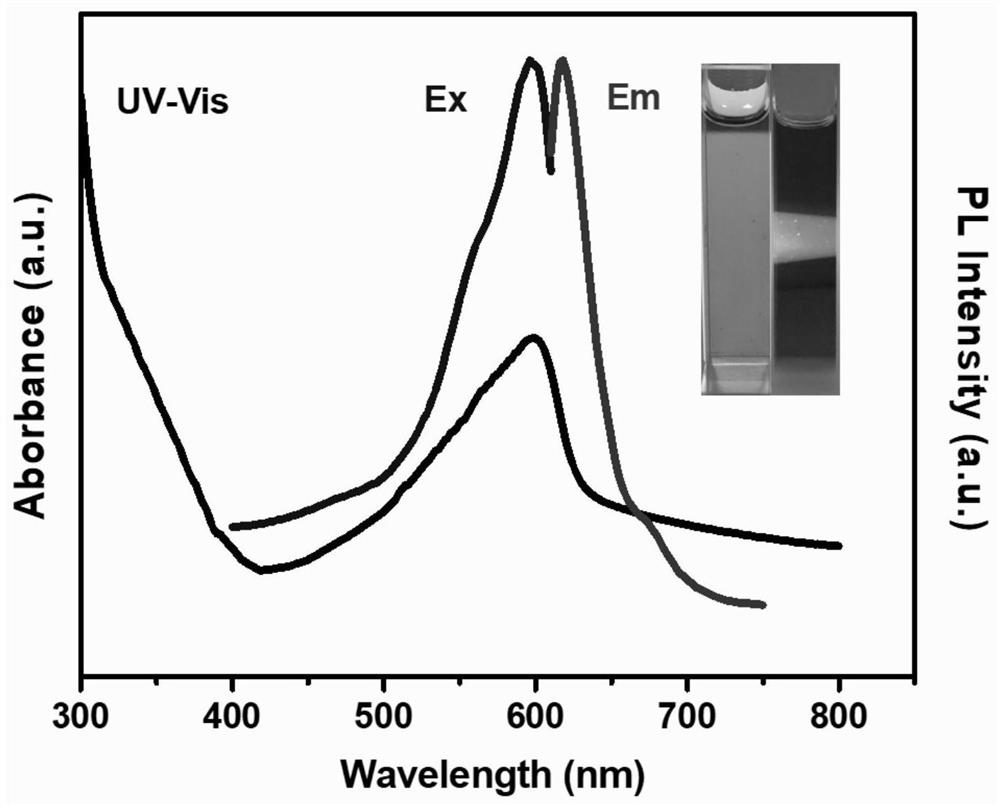

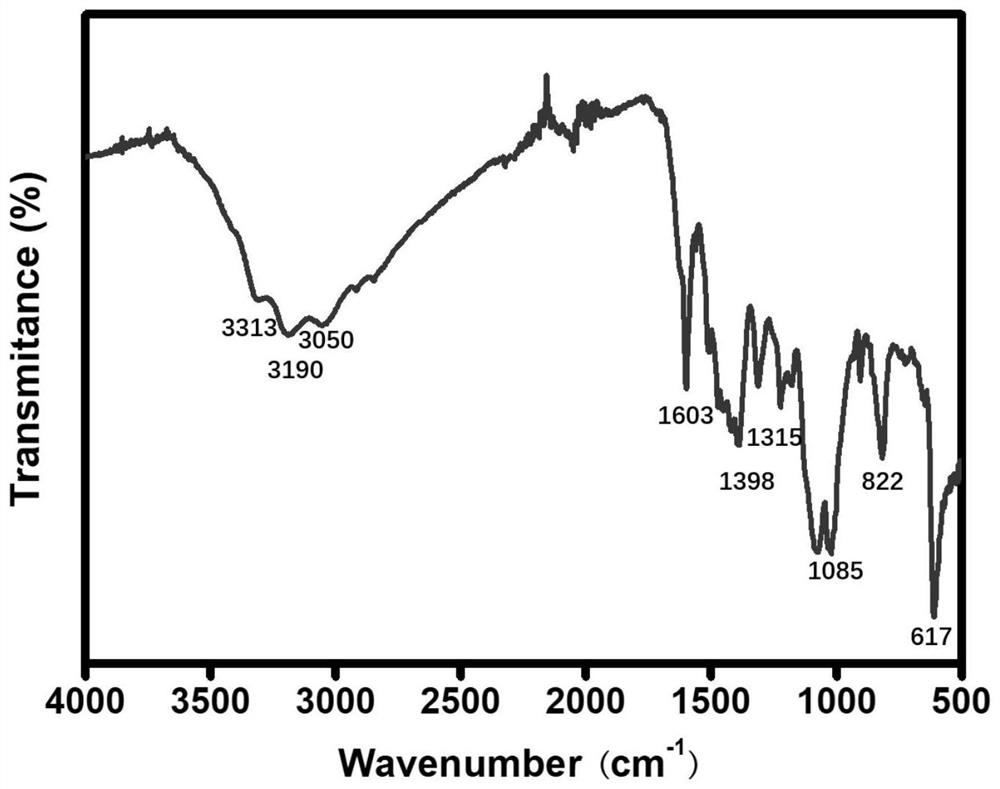

Nitrogen-sulfur-doped efficient red light emission carbon dot, preparation method and application thereof

A carbon dot, high-efficiency technology, applied in chemical instruments and methods, nano optics, luminescent materials, etc., can solve the problems of complicated and expensive instruments, time-consuming experimental process, toxic reagents, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dissolve 0.054g of o-phenylenediamine and 0.38g of ammonium thiocyanate in 5mL of ultrapure water at a molar ratio of 1:10, and stir for 20min at room temperature in a nitrogen atmosphere to form a uniform mixed solution. Move the mixed solution to a high-pressure reactor, and place it in an oven at 150°C for 12 hours; after the reaction, cool down to room temperature to take out the original solution of carbon dots, and remove the original solution by centrifuging at a constant temperature of 8000rpm at 25°C for 25min. A lump precipitated and a dark red supernatant was obtained. Take the centrifuged solution above and use a dialysis bag with a molecular weight cut-off of 100DA to remove small molecular impurities to obtain a relatively pure carbon dot solution; freeze-dry the dialyzed carbon dot solution for 20 hours to obtain solid carbon dot powder.

Embodiment 2

[0035]Take 0.054g of m-phenylenediamine and 0.19g of sodium thiocyanate dissolved in 5mL of ultrapure water, the molar ratio is 1:5, and stirred at room temperature and nitrogen atmosphere for 20min to form a uniform mixed solution. Move the mixed solution to a high-pressure reactor, and place it in an oven at 200°C for 12 hours; after the reaction, cool to room temperature to take out the original solution of carbon dots, and remove the original solution by centrifuging at a constant temperature of 8000rpm at 25°C for 25min. A lump precipitated and a dark red supernatant was obtained. Take the centrifuged solution above and use a dialysis bag with a molecular weight cut-off of 100DA to remove small molecular impurities to obtain a relatively pure carbon dot solution; freeze-dry the dialyzed carbon dot solution for 20 hours to obtain solid carbon dot powder.

Embodiment 3

[0037] Dissolve 0.054g of p-phenylenediamine and 0.38g of ammonium thiocyanate in 5mL of ultrapure water with a molar ratio of 1:10, and stir at room temperature for 20min in a nitrogen atmosphere to form a uniform mixed solution. Move the mixed solution to a high-pressure reactor, and place it in an oven at 200°C for 12 hours; after the reaction, cool to room temperature to take out the original solution of carbon dots, and remove the original solution by centrifuging at a constant temperature of 8000rpm at 25°C for 25min. A lump precipitated and a dark red supernatant was obtained. Take the centrifuged solution above and use a dialysis bag with a molecular weight cut-off of 100DA to remove small molecular impurities to obtain a relatively pure carbon dot solution; freeze-dry the dialyzed carbon dot solution for 20 hours to obtain solid carbon dot powder.

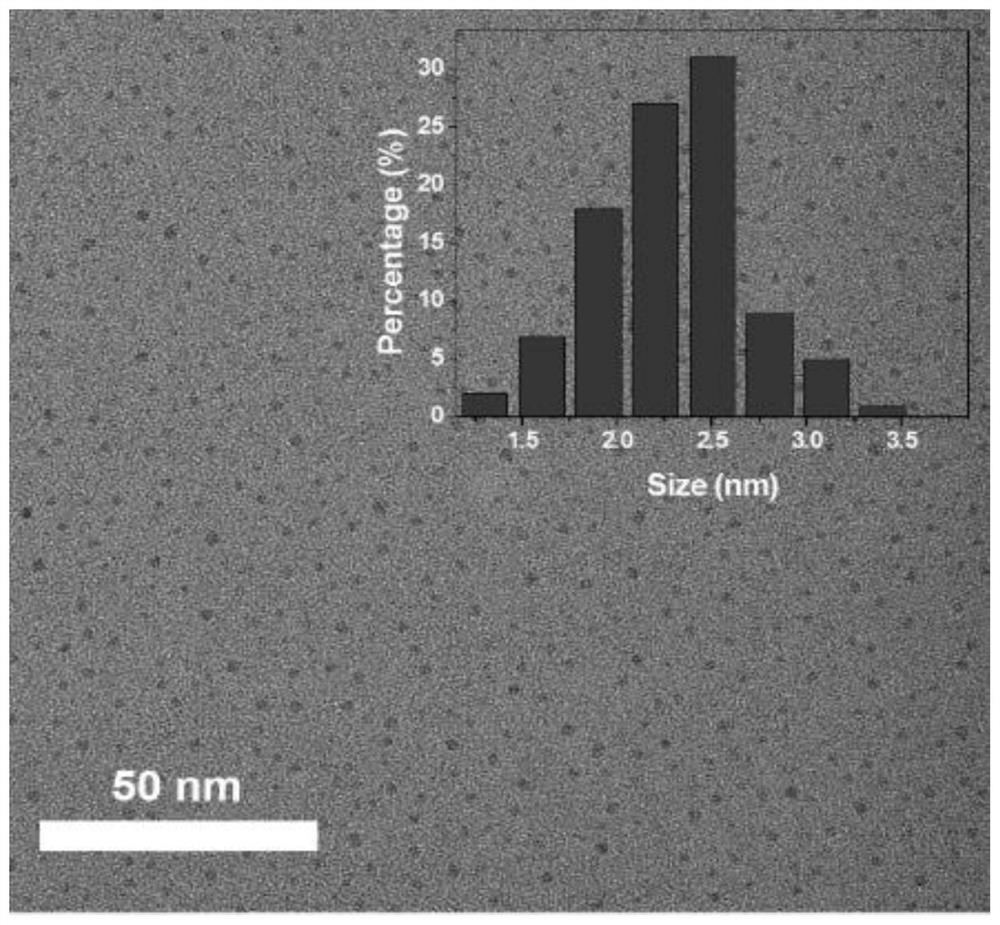

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com