Method for determining eutectic point components in multi-element alloy phase diagram

A technology for multi-element alloys and determination methods, which is applied in the field of alloy materials and can solve the problems of inability to calculate the composition of eutectic points, taking a lot of time, and a lot of experiments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

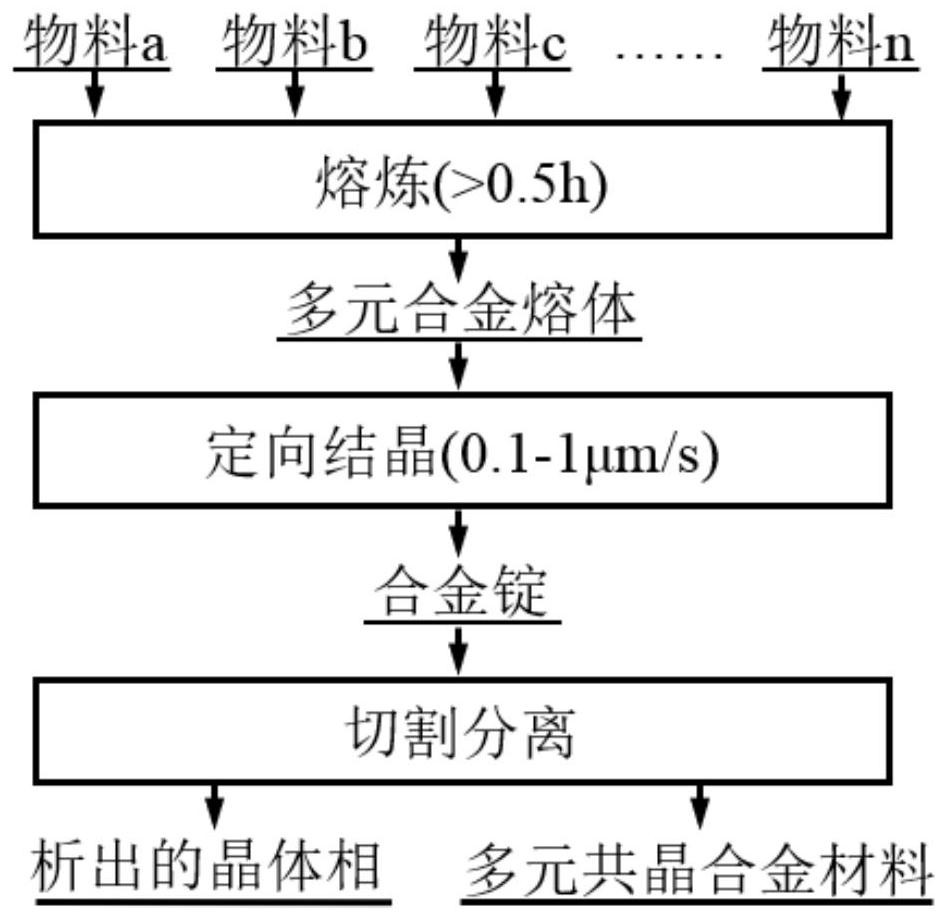

[0025] Example 1: A method for determining the composition of the eutectic point in the phase diagram of a multi-element alloy (see figure 1 ),Specific steps are as follows:

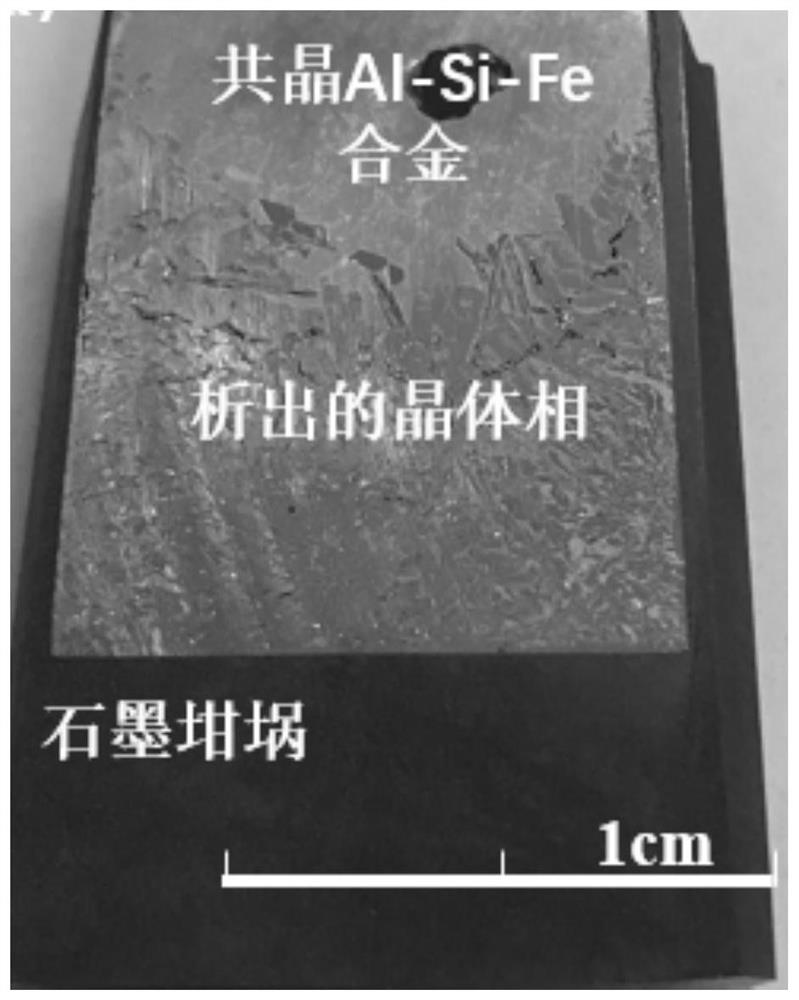

[0026] (1) Mix high-purity iron (99.95%), high-purity silicon (99.9999%) and high-purity aluminum (99.999%) evenly, place the mixture in an electromagnetic induction furnace with a directional crystallization device, and place it in a protective gas atmosphere ( Induction heating in argon gas) to complete melting and holding for 1h to obtain a multi-component alloy melt; the molar ratio of iron, silicon and aluminum is 4:42:54;

[0027] (2) performing directional crystallization of the multi-component alloy melt in step (1) under electromagnetic induction heating to obtain a crystal phase and a multi-component eutectic alloy; wherein the directional crystallization is to move the multi-component alloy melt directionally out of the heating zone at a speed of 1 μm / s, and the multi-component alloy melt is d...

Embodiment 2

[0030] Example 2: A method for determining the composition of the eutectic point in a multi-element alloy phase diagram (see figure 1 ),Specific steps are as follows:

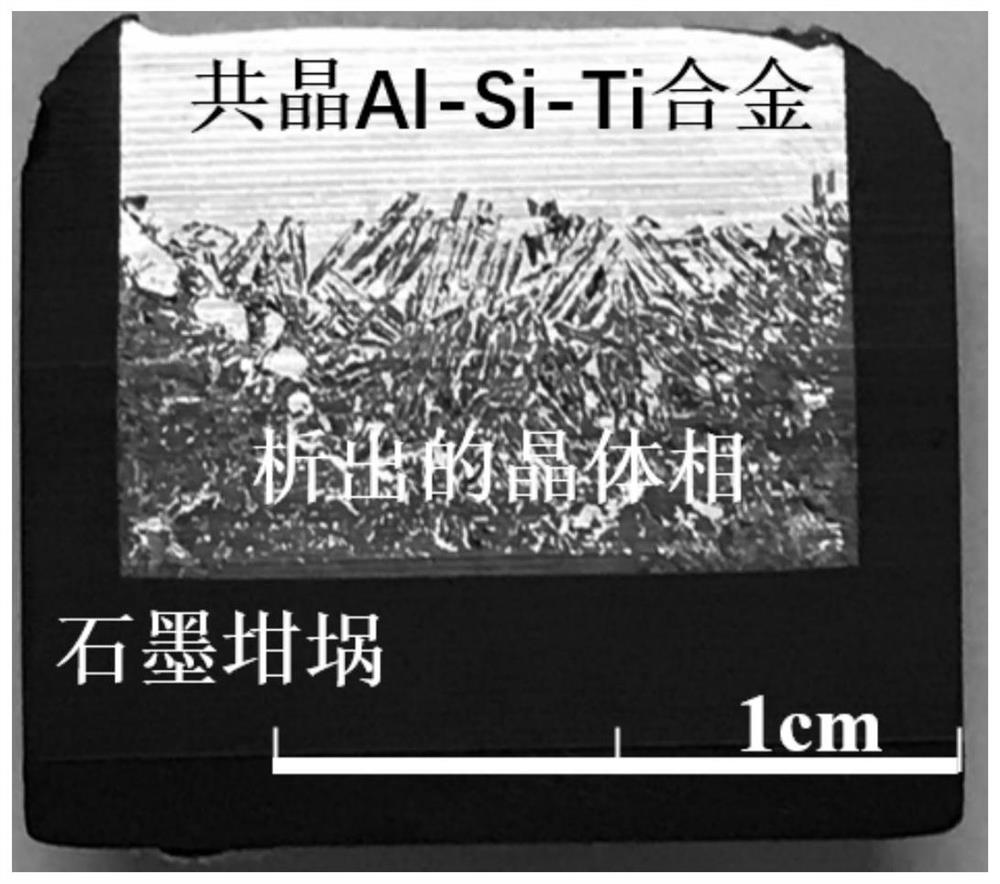

[0031] (1) Mix high-purity titanium (99.9%), high-purity silicon (99.9999%) and high-purity aluminum (99.999%) evenly, place the mixture in an electromagnetic induction furnace with a directional crystallization device, and place it in a protective gas Induction heating in the atmosphere (helium) to complete melting and holding for 0.5h to obtain a multi-component alloy melt; the molar ratio of titanium, silicon and aluminum is 5:50:45;

[0032] (2) performing directional crystallization of the multi-element alloy melt in step (1) under electromagnetic induction heating to obtain a crystal phase and a multi-element eutectic alloy; wherein the directional crystallization is to move the multi-element alloy melt directionally out of the heating zone at a speed of 4 μm / s, and the multi-element eutectic alloy Si an...

Embodiment 3

[0035] Example 3: A method for determining the composition of the eutectic point in the phase diagram of a multi-element alloy (see figure 1 ),Specific steps are as follows:

[0036] (1) Mix high-purity iron (99.95%), high-purity manganese (99.8%), high-purity silicon (99.9999%) and high-purity aluminum (99.999%) evenly, and place the mixture in an electromagnetic induction furnace with a directional crystallization device , and induction heating in a protective gas atmosphere (argon) to complete melting and holding for 0.5h to obtain a multi-component alloy melt; the molar ratio of titanium, manganese, silicon and aluminum is 3.85:3.85:40.38:51.92;

[0037] (2) performing directional crystallization of the multi-element alloy melt in step (1) under electromagnetic induction heating to obtain a crystal phase and a multi-element eutectic alloy; wherein the directional crystallization is to orient the induction heating coil upward and away from the multi-element alloy melt at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com