Al-centered polymer electrolyte and preparation method and application thereof

A composite electrolyte and polymer technology, applied in the field of electrochemical energy storage, can solve the problems of low lithium ion migration number, narrow electrochemical window, and low conductivity, and achieve wide electrochemical window, high conductivity, and easy preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a polymer electrolyte centered on Al, comprising the following steps:

[0045] S1, the aluminum source and R 1 The raw materials are stirred evenly under an inert atmosphere, heated to 50-200°C, and reacted for 0.5-10 hours to obtain a precursor monomer;

[0046] S2, adding lithium salt to the precursor monomer obtained in step S1 at room temperature, stirring and reacting for 0.5-3 hours under an inert atmosphere, to obtain a precursor monomer containing lithium salt;

[0047] S3, R at room temperature 2 Add the raw material to the lithium salt-containing precursor obtained in step S2, stir and react under an inert atmosphere for 0.5-5 hours, raise the temperature to 50-200° C., and continue the reaction for 0.5-10 hours to obtain a lithium-salt-containing polymer;

[0048] S4. Distilling under reduced pressure to remove impurities in the lithium salt-containing polymer to obtain a high-purity polymer electrolyte.

[0049]In the above preparat...

Embodiment 1

[0052] A method for preparing a polymer electrolyte centered on Al, comprising the following steps:

[0053] S1. Add 1.62g of aluminum ethoxide and 5.5g of mPEG550 into the flask, pass in an inert gas and stir for 1 hour to form a uniform mixture, heat at 100°C, and react for 2 hours to prepare the precursor monomer.

[0054] S2. Add 2.44 g of LiODFB after cooling down to room temperature, and continue stirring for 1 hour to obtain a lithium-containing precursor monomer.

[0055] S3. Add 2 g of PEG200 at room temperature, stir for 1 h, then raise the temperature to 100° C., and react for 2 h to obtain a lithium salt-containing polymer.

[0056] S4. Distilling under reduced pressure at 80° C. to remove small molecule alcohol impurities generated by the reaction to obtain the high-purity polymer electrolyte.

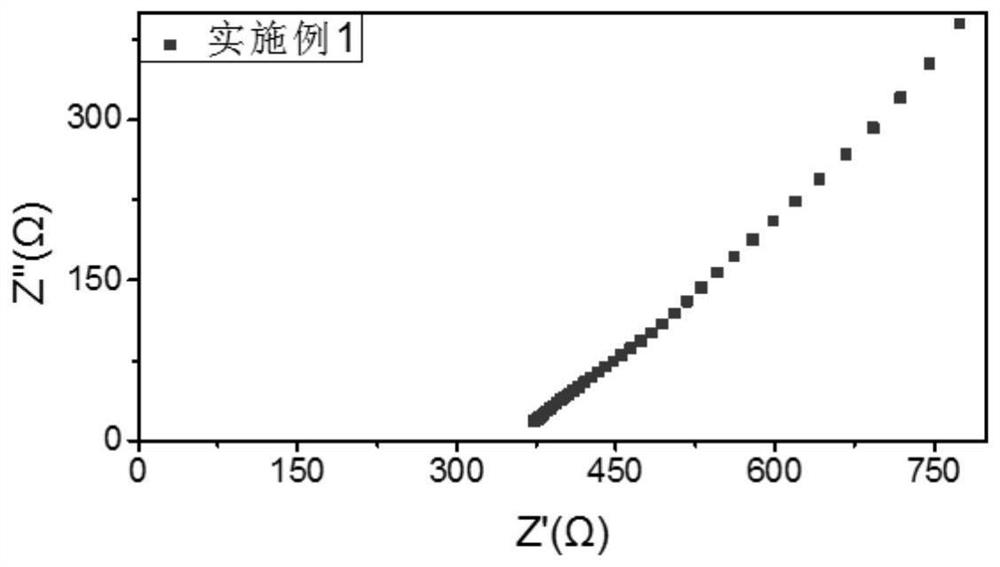

[0057] Conductivity test: hot press the polymer electrolyte prepared in this example into a Φ16mm disc P1 with a thickness of 1.125mm, and then make a battery of stainles...

Embodiment 2

[0060] A method for preparing a polymer electrolyte centered on Al, comprising the following steps:

[0061] S1. Add 2.04g of aluminum isopropoxide and 7.93g of mPEG-Ph-FSI into the flask, pass in an inert gas and stir for 2 hours to form a uniform mixture, heat at 90°C, and react for 10 hours to prepare the precursor monomer.

[0062] S2. Add 4.1 g of LiFSI after cooling down to room temperature, and continue stirring for 3 hours to obtain a lithium-containing precursor monomer.

[0063] S3. Add 6.43 g of PEG-Ph-FSI at room temperature, stir for 1 h, then raise the temperature to 120° C., and react for 4 h to obtain a lithium-containing polymer.

[0064] S4. Distilling under reduced pressure at 80° C. to remove small molecule alcohol impurities generated by the reaction to obtain the high-purity polymer electrolyte.

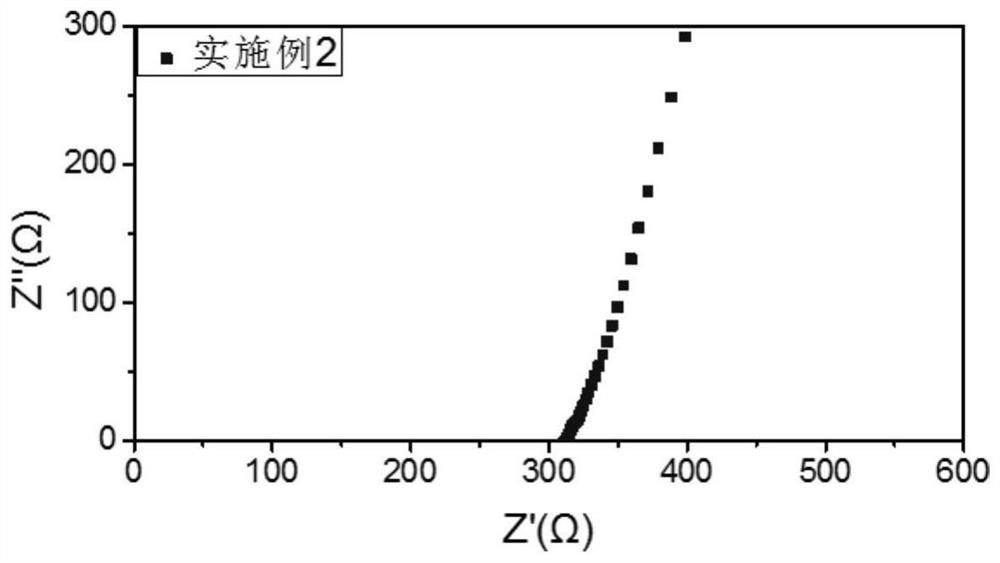

[0065] Conductivity test: The polymer electrolyte prepared in this example is hot-pressed into a Φ16mm disc P2 with a thickness of 2.294mm, and then made into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com