3D printing titanium alloy and preparation method thereof

A 3D printing and titanium alloy technology, applied in the field of titanium alloys, can solve the problems of not being able to meet the requirements of clinical surface osteoblast adhesion to promote bone formation, so as to eliminate the risk of clinical use, meet the requirements of osteoblast adhesion and promote bone formation, and reduce The effect of evaluation and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

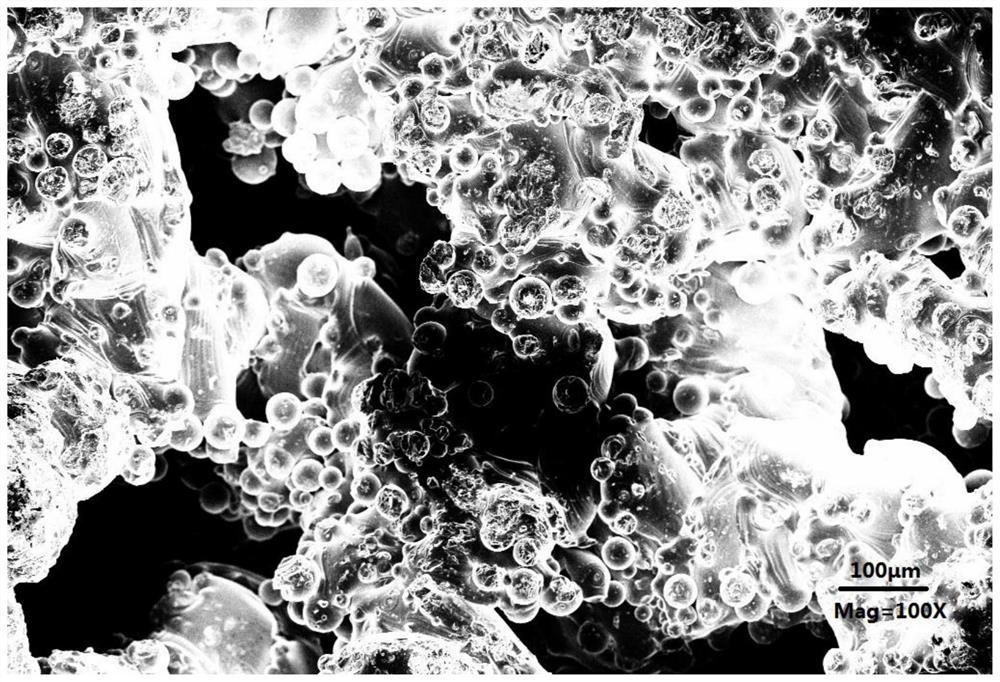

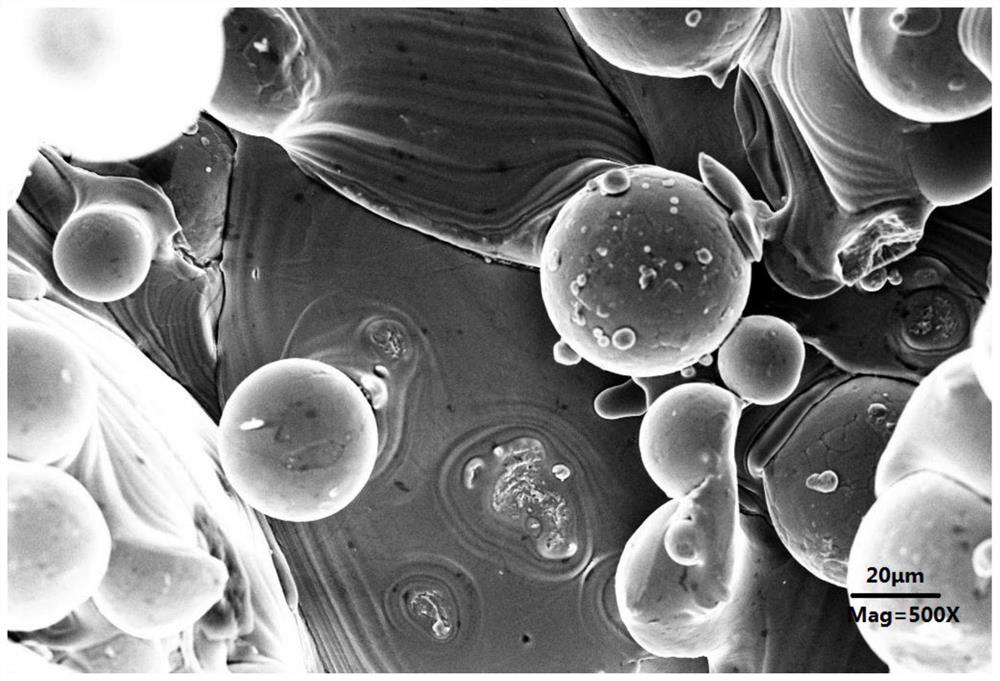

[0040] S1. Using titanium alloy particles with a particle size of 0.5-50 μm as raw materials, the 3D printed titanium alloy body is formed by laser melting. The laser melting conditions include a power of 150W and a printing speed of 1000mm / s. The surface SEM image of the 3D printed titanium alloy body is as follows figure 1 with figure 2 As shown, among them, figure 1 The magnification is 100 times, figure 2 The magnification is 500 times. from figure 1 with figure 2 It can be seen that the surface of the 3D printed titanium alloy body has a bone trabecular structure, and a large number of semi-fused spherical particles are attached to the bone trabecular structure, and the surface of the unattached area is smooth without special microporous structure.

[0041] S2. Place the 3D printed titanium alloy body in PWC-401 cleaning agent and ultrasonically clean it at 65°C for 10 minutes. After cleaning, use 608-mesh ceramic sand for sandblasting. The high-pressure water wa...

Embodiment 2

[0046] S1. Using titanium alloy particles with a particle size of 0.5-50 μm as raw materials, a 3D printed titanium alloy body is formed by laser melting. The laser melting conditions include a power of 200W and a printing speed of 2000mm / s. According to SEM detection, the surface of the 3D printed titanium alloy body has a bone trabecular structure, and a large number of semi-fused spherical particles are attached to the bone trabecular structure, and the surface of the unattached area is smooth without special microporous structure.

[0047] S2. Place the 3D printed titanium alloy body in PWC-401 cleaning agent and ultrasonically clean it at 65°C for 10 minutes. After cleaning, use 1000-mesh titanium sand for sandblasting. The high-pressure water was washed under the pressure of 100kg for 1200s, and then dried to obtain the pretreated 3D printing titanium alloy.

[0048] S3. Clean the pretreated 3D printed titanium alloy with vacuum plasma. The specific conditions include th...

Embodiment 3

[0051] S1. Using titanium alloy particles with a particle size of 0.5-50 μm as raw materials, the 3D printed titanium alloy body is formed by laser melting. The laser melting conditions include a power of 100W and a printing speed of 800mm / s. According to SEM detection, the surface of the 3D printed titanium alloy body has a bone trabecular structure, and a large number of semi-fused spherical particles are attached to the bone trabecular structure, and the surface of the unattached area is smooth without special microporous structure.

[0052] S2. Place the 3D printed titanium alloy body in PWC-401 cleaning agent and ultrasonically clean it at 65°C for 10 minutes. After cleaning, use 60-mesh white corundum sand for sandblasting treatment. The sandblasting pressure is 3bar and the sandblasting distance is 15cm. After that Rinse with high-pressure water for 600s under a pressure of 500kg, and then dry to obtain a pretreated 3D printed titanium alloy.

[0053] S3. Place the pret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com