Polishing equipment for curved glass

A curved glass and equipment technology, applied in grinding/polishing equipment, surface polishing machine tools, metal processing equipment, etc., can solve the problem that the upper and lower surfaces of the curved glass cannot be polished at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

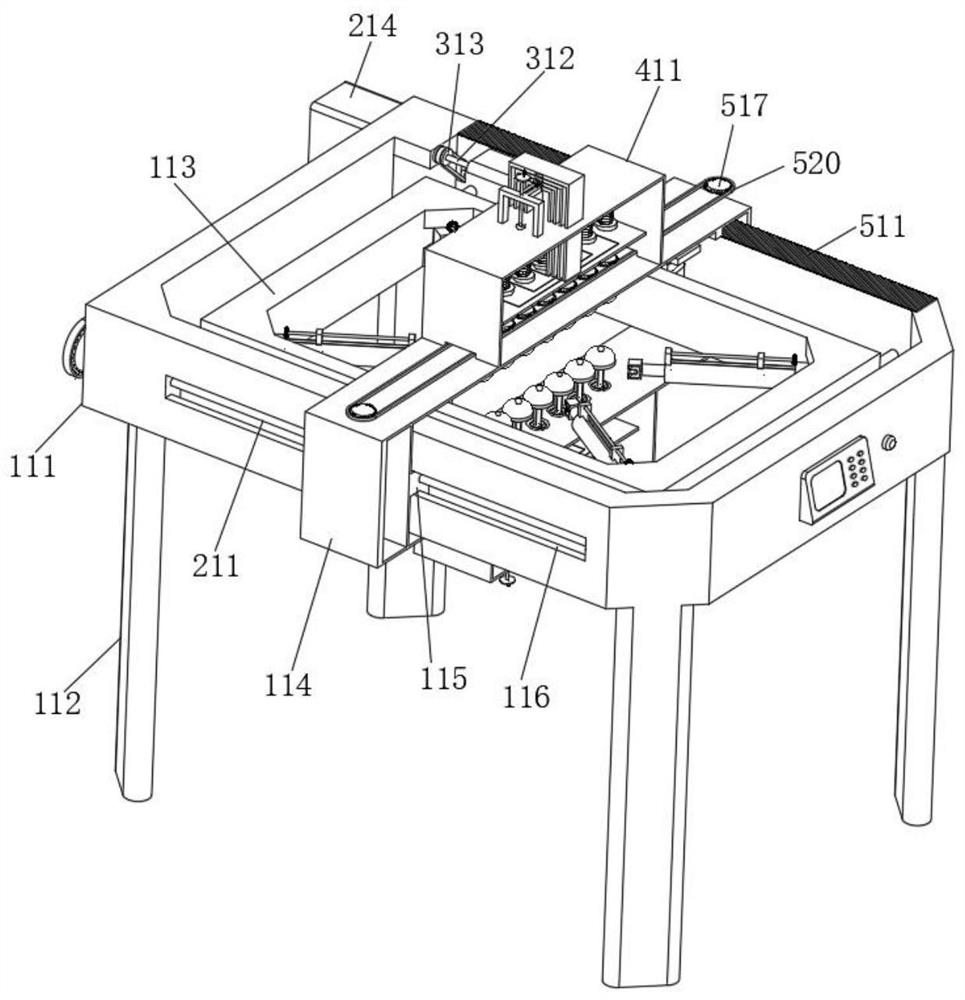

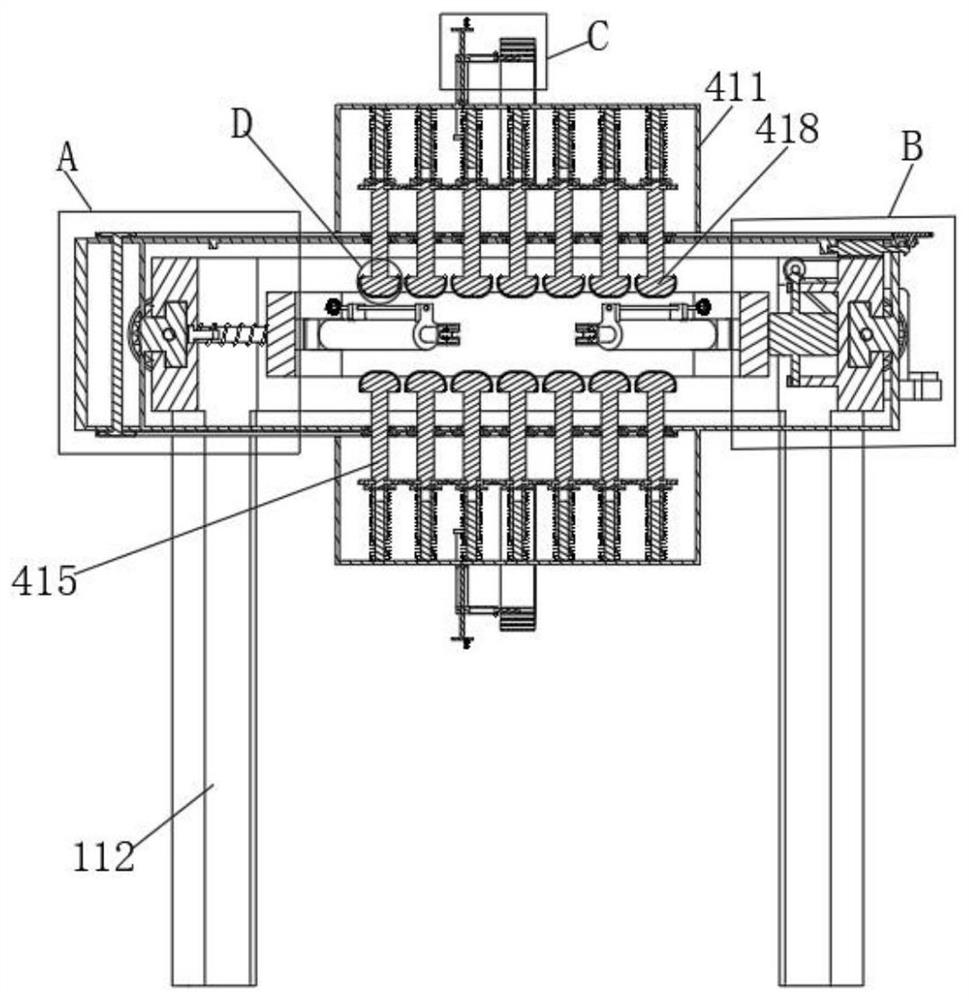

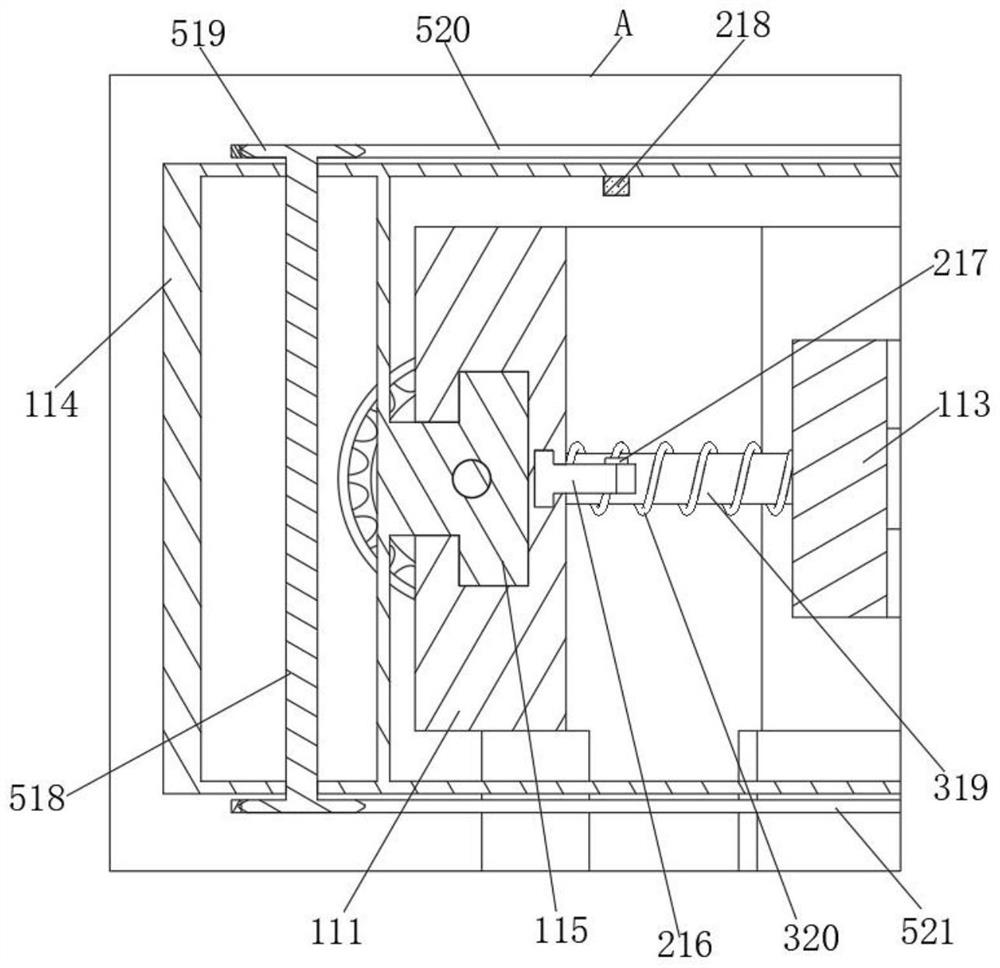

[0036] see Figure 1-19 , an embodiment provided by the present invention: a polishing device for curved glass, including a first mounting frame 111, a servo motor 214, a signal receiver 217 and a signal generator 218, and the four corners at the lower end of the first mounting frame 111 are all The supporting legs 112 are fixedly connected, and the inside of the first mounting frame 111 is slidably connected with the second mounting frame 113, and the middle part of the first mounting frame 111 is slidingly connected with the third mounting frame 114, and the inner walls of the front and rear ends of the third mounting frame 114 are All are fixedly connected with the first slider 115, and the first slider 115 on the front and rear sides is engaged with the front and rear ends of the first installation frame 111 respectively, and the middle part of the front and rear openings of the first installation frame 111 is provided with the first slider. The first chute 116 that the bl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap