Tungsten bronze type high-temperature thermistor material and preparation method thereof

A technology of tungsten bronze and sensitive resistors, which is applied in the field of new thermistor materials, can solve the problems of deterioration of thermal performance and unstable phase structure, and achieve the effect of good consistency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

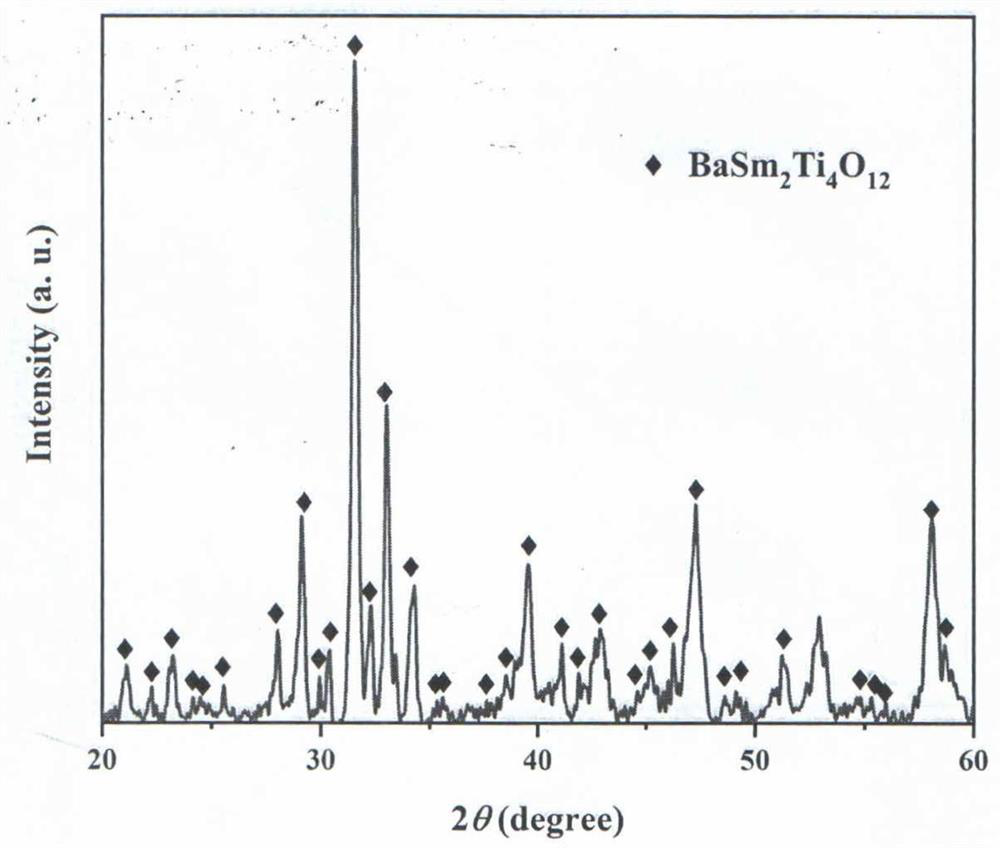

[0020] a. First press BaSm 2 Ti 4 o 12 6.8642g of analytically pure barium carbonate, 12.0204g of samarium trioxide and 11.1154g of titanium dioxide were weighed and mixed respectively, and the mixed raw materials were placed in an agate mortar and ground for 6 hours to obtain a powder;

[0021] b. Calcinate the ground powder in step a at a temperature of 1000°C for 4 hours, and then grind for 5 hours to obtain BaSm 2 Ti 4 o 12 Powder;

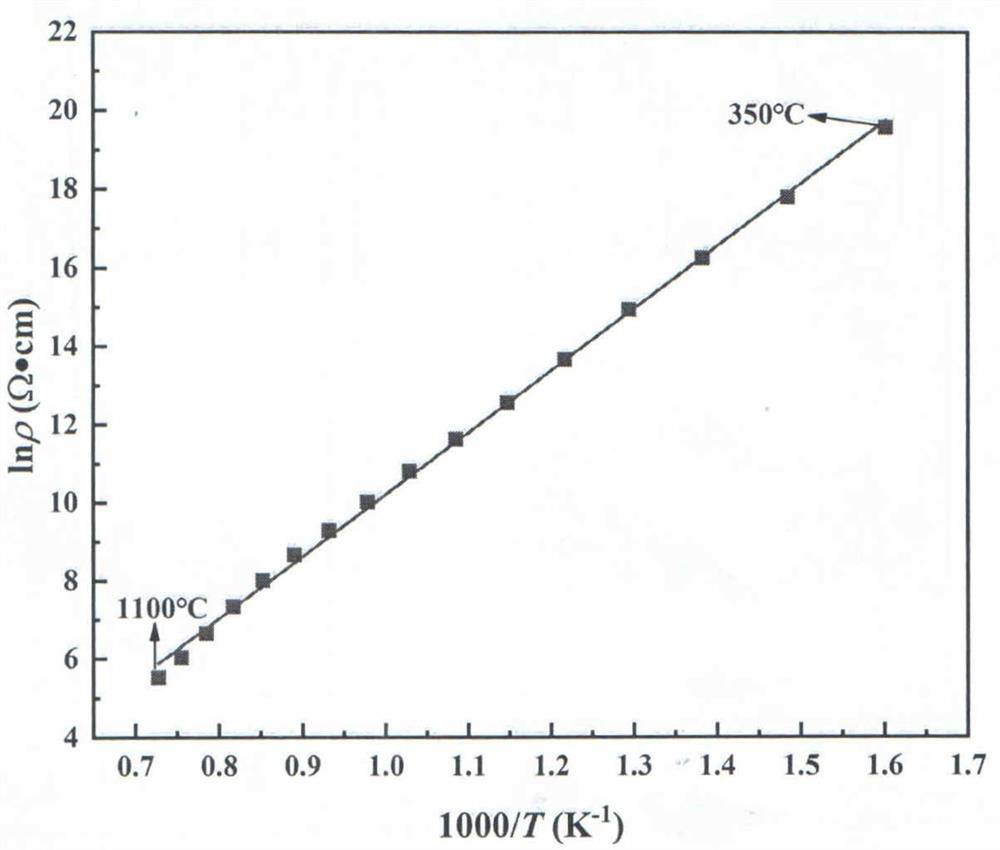

[0022] c, the powder material that step b obtains is with 10Kg / cm 2 The pressure is briquetted for 0.5 minutes, and the formed block material is subjected to cold isostatic pressing, kept at a pressure of 250MPa for 1 minute, and then sintered at a temperature of 1300°C for 4 hours to obtain a high-temperature heat-sensitive ceramic material ;

[0023] d. Coat the front and back sides of the ceramic material sintered in step c with platinum paste electrodes, and then anneal at 900°C for 30 minutes to obtain a negative temperature coeffi...

Embodiment 2

[0025] a. Press BaSm 2 Ti 4 o 12 The composition of barium carbonate 6.8642g, samarium trioxide 12.0204g and titanium dioxide 11.1154g were weighed and mixed respectively, and the mixed raw materials were placed in an agate mortar and ground for 7 hours to obtain a powder;

[0026] b. Calcinate the ground powder in step a at a temperature of 1125°C for 5 hours, and grind for 6 hours to obtain BaSm 2 Ti 4 o 12 Powder;

[0027] c, the powder material that step b obtains is with 15Kg / cm 2 The pressure is briquetted for 1 minute, and the formed block material is subjected to cold isostatic pressing, kept at a pressure of 300MPa for 2 minutes, and then sintered at a temperature of 1325°C for 5 hours to obtain a high-temperature heat-sensitive ceramic material ;

[0028] d. Coat the front and back sides of the ceramic material sintered in step c with platinum paste electrodes, and then anneal at a temperature of 900°C for 30 minutes to obtain a negative temperature coefficien...

Embodiment 3

[0030] a. Press BaSm 2 Ti 4 o 12 The composition of barium carbonate 6.8642g, samarium trioxide 12.0204g and titanium dioxide 11.1154g were weighed respectively and mixed, and the mixed raw materials were placed in an agate mortar and ground for 8 hours to obtain a powder;

[0031] b. Calcinate the ground powder in step a at a temperature of 1150°C for 6 hours, and grind for 7 hours to obtain BaSm2 Ti 4 o 12 Powder;

[0032] c, the powder material that step b obtains is with 15Kg / cm 2 The pressure is briquetted, and the time is 1 minute. The formed block material is subjected to cold isostatic pressing, kept at a pressure of 300 MPa for 3 minutes, and then sintered at a temperature of 1350 ° C for 6 hours to obtain a high-temperature heat-sensitive ceramic material. ;

[0033] d. Coat the front and back sides of the ceramic material sintered in step c with platinum paste electrodes, and then anneal at a temperature of 900°C for 30 minutes to obtain a negative temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com