Environmental response type well cementation filter cake removing liquid

An environmental response and scavenging liquid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of filter cake removal efficiency decline, inability to play, and scavenger decomposition failure, etc., to achieve the effect and speed up The effect of short reaction speed and clearing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

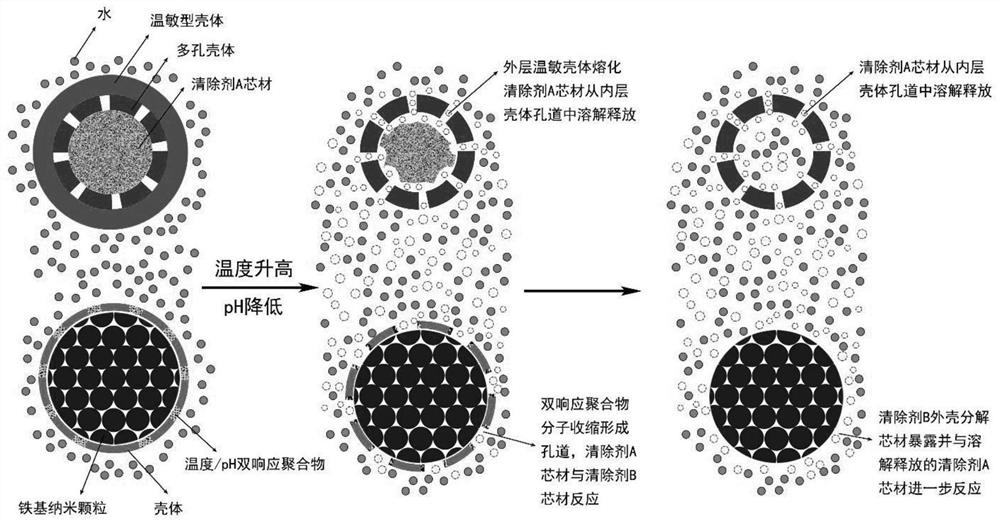

Method used

Image

Examples

Embodiment 1

[0042] An environment-responsive cementing filter cake removal fluid, the cementing filter cake removal fluid comprises: an environmental-responsive scavenger A, an environmental-responsive scavenger B, a surfactant, a suspending agent, a stabilizer and water, and its preparation method details as follows:

[0043] Adopt NaOH to adjust the pH of water to 8, with 10 parts by weight of environment-responsive scavenger A, 1 part by weight of environment-responsive scavenger B, 0.5 parts by weight of nonylphenol polyoxyethylene ether (as surfactant), 0.2 parts by weight Octylphenol polyoxyethylene ether, 0.05 parts by weight of lauryl alcohol polyoxyethylene ether (as surfactant), 1.2 parts by weight of xanthan gum (as suspending agent), 0.5 parts by weight of AMPS (2-acrylamide-2-methyl propanesulfonic acid) and AM (acrylamide) and MA (maleic anhydride) copolymer (as suspending agent), 2.5 parts by weight of attapulgite and nano silica mixture (as stabilizer, attapulgite and nano...

Embodiment 2

[0055] An environment-responsive cementing filter cake removal fluid, the cementing filter cake removal fluid comprises: an environmental-responsive scavenger A, an environmental-responsive scavenger B, a surfactant, a suspending agent, a stabilizer and water, and its preparation method details as follows:

[0056] Adopt NaOH to adjust the pH of water to 9, with 15 parts by weight of environment-responsive scavenger A, 2.5 parts by weight of environment-responsive scavenger B, 1 part by weight of octylphenol polyoxyethylene ether (as surfactant), 0.5 parts by weight Fatty alcohol polyoxyethylene ether (as surfactant), 0.5 parts by weight of sodium dodecylbenzene sulfonate (as surfactant), 1.0 parts by weight of carboxymethyl cellulose (as suspending agent), 0.7 parts by weight of AMPS and DAAM (diacetone acrylamide) and AM copolymer (as suspending agent), 2 parts by weight of attapulgite and nano-silica mixture (as a stabilizer, the weight ratio of attapulgite and nano-silica ...

Embodiment 3

[0068] An environment-responsive cementing filter cake removal fluid, the cementing filter cake removal fluid comprises: an environmental-responsive scavenger A, an environmental-responsive scavenger B, a surfactant, a suspending agent, a stabilizer and water, and its preparation method details as follows:

[0069] Adopt NaOH to adjust the pH of water to 9, with 10 parts by weight of environment-responsive scavenger A, 2 parts by weight of environment-responsive scavenger B, 2 parts by weight of nonylphenol polyoxyethylene ether (as surfactant), 1.5 parts by weight Sodium dodecylbenzenesulfonate (as surfactant), 1.5 parts by weight of hydroxyethyl cellulose (as suspending agent), 1 part by weight of AMPS and AM, the copolymer of MA (as suspending agent), 3 parts by weight of concavo-convex A mixture of palygorskite and nano-silica (as a stabilizer, the weight ratio of attapulgite to nano-silica is 70:30) is added to 100 parts by weight of prepared water with a pH of 9, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com