A multi-phase gel with multi-stable mechanics and shape memory properties and its preparation method

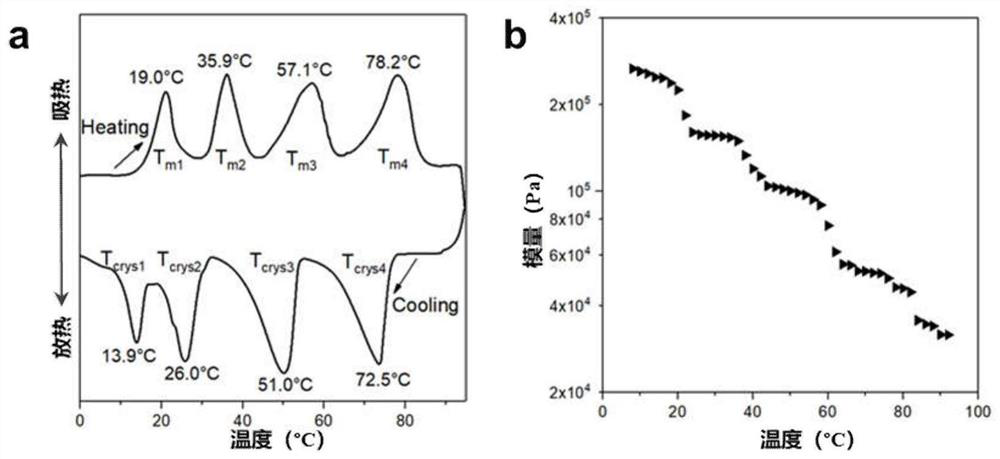

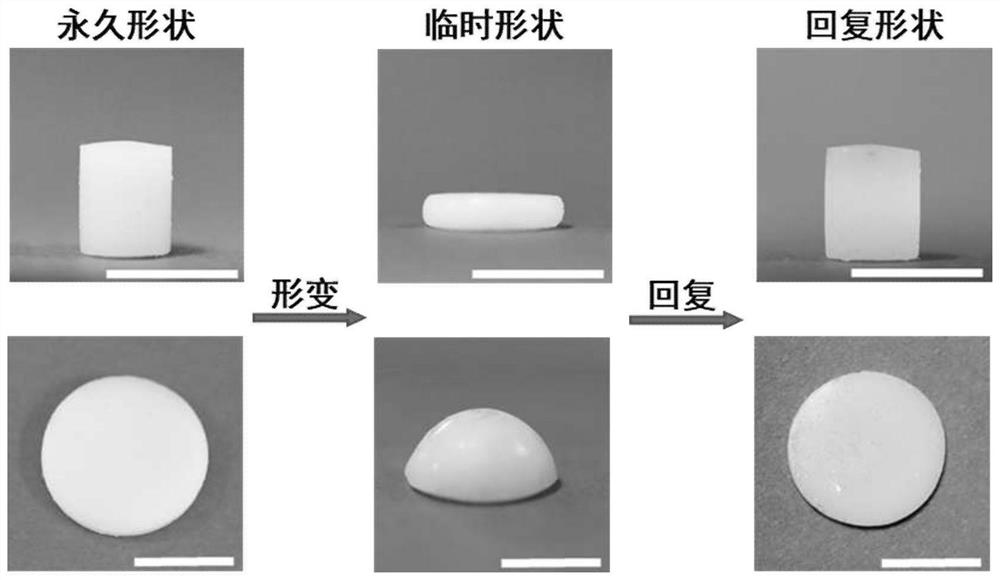

A multi-stable and mechanical technology, applied in the field of materials, can solve the problems of limited mechanical transformation and shape memory performance, unfavorable rapid recovery of original shape, and difficult application of this material, achieving excellent multi-level regulation and controllability Effects of enhanced shape memory and sensitivity, improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

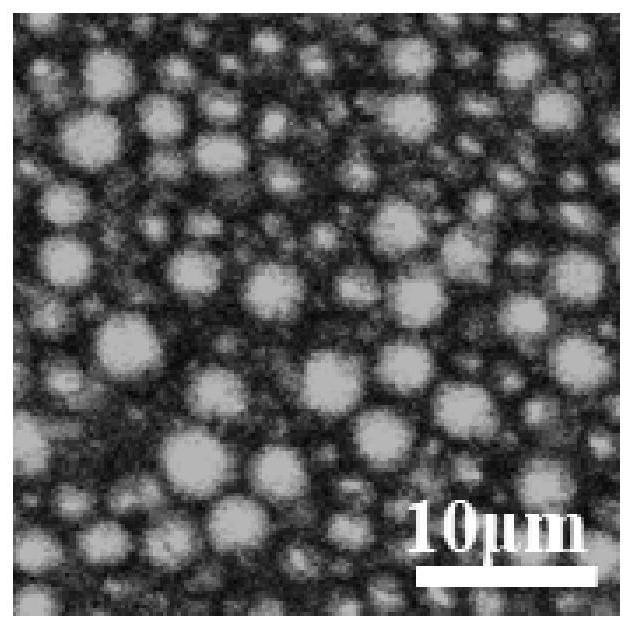

[0060] Room temperature stable heterogeneous ionic liquid gel with mechanically tunable and shape memory properties and its preparation method:

[0061] 1) Add 0.3g of 1-butyl-3-methylimidazolium hexafluorophosphate, 0.2g of N,N-dimethylacrylamide (1-butyl-3-methylimidazolium hexafluorophosphate and N,N - The mass ratio of dimethylacrylamide is 1.5:1), 3 mg of ethylene glycol dimethacrylate (accounting for 1 / 100 of the mass of 1-butyl-3-methylimidazolium hexafluorophosphate) and 2,2 - 0.3 mg of diethoxyacetophenone (accounting for 1 / 10000 of the mass of 1-butyl-3-methylimidazolium hexafluorophosphate) is mixed, adding 2 mg of 5% sodium lauryl sulfate aqueous solution , to obtain the mixed solution of the ionic liquid phase after fully mixing;

[0062] 2) Hexadecane 0.29g, hexadecane 0.29g (hexadecane and hexadecane accounted for 50% respectively), stearyl methacrylate 0.29g, ethylene glycol dimethacrylate 2.9mg ( 1 / 100 of the mass of octadecyl methacrylate) and 1 mg of 2,2-d...

Embodiment 2

[0066] Multiphase hydrogel with mechanically tunable and shape memory properties and preparation method thereof:

[0067] 1) Mix 0.4g of water, 0.1g of N,N-dimethylacrylamide (the mass ratio of water to N,N-dimethylacrylamide is 4:1), 32mg of XLS-type clay tablets (accounting for 8% of the water quality). / 100) and 1 mg of 2,2-diethoxyacetophenone (accounting for 2.5 / 1000 of the water quality) are mixed, and the water phase mixed solution is obtained after fully mixing;

[0068] 2) Add 0.22g of hexadecane, 0.22g of octadecane, 0.22g of hexadecaneol (33% of hexadecane, octadecane and hexadecyl alcohol), 0.21g of lauryl methacrylate , 1 mg of ethylene glycol dimethacrylate (accounting for 5 / 1000 of the mass of lauryl methacrylate) and 1 mg of 2,2-diethoxyacetophenone (accounting for 5 / 1000 of the mass of lauryl methacrylate) Mix and heat in a water bath at a temperature of about 80°C, mix well to obtain an oil phase mixed solution;

[0069] 3) Add the solution prepared in step...

Embodiment 3

[0072] Room temperature stable heterogeneous ionic liquid gel with mechanically tunable and shape memory properties and its preparation method:

[0073] 1) Add 0.45g of 1-butyl-3-methylimidazolium methanesulfonate and 0.05g of acrylic acid (the mass ratio of 1-butyl-3-methylimidazolium methanesulfonate to acrylic acid is 9:1) , 2.25mg of ethylene glycol diethylacrylate (accounting for 5 / 1000 of the mass of 1-butyl-3-methylimidazolium methanesulfonate) and 1mg of 2,2-diethoxyacetophenone (accounting for 1 -2.2 / 1000 of butyl-3-methylimidazolium methanesulfonate quality) mixes, obtains the mixed solution of ionic liquid phase after fully mixing;

[0074]2) Add 0.17g of hexadecane, 0.19g of octadecane, 0.18g of hexadecane, and 0.17g of tetratetradecane (respectively 19.1%, 21.3%, 20.2%, 19.1%), stearyl methacrylate 0.18g, ethylene glycol dimethacrylate 0.9mg (accounting for 5 / 1000 of the mass of stearyl methacrylate) and 2,2 - 0.1 mg of diethoxyacetophenone (accounting for 5 / 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com