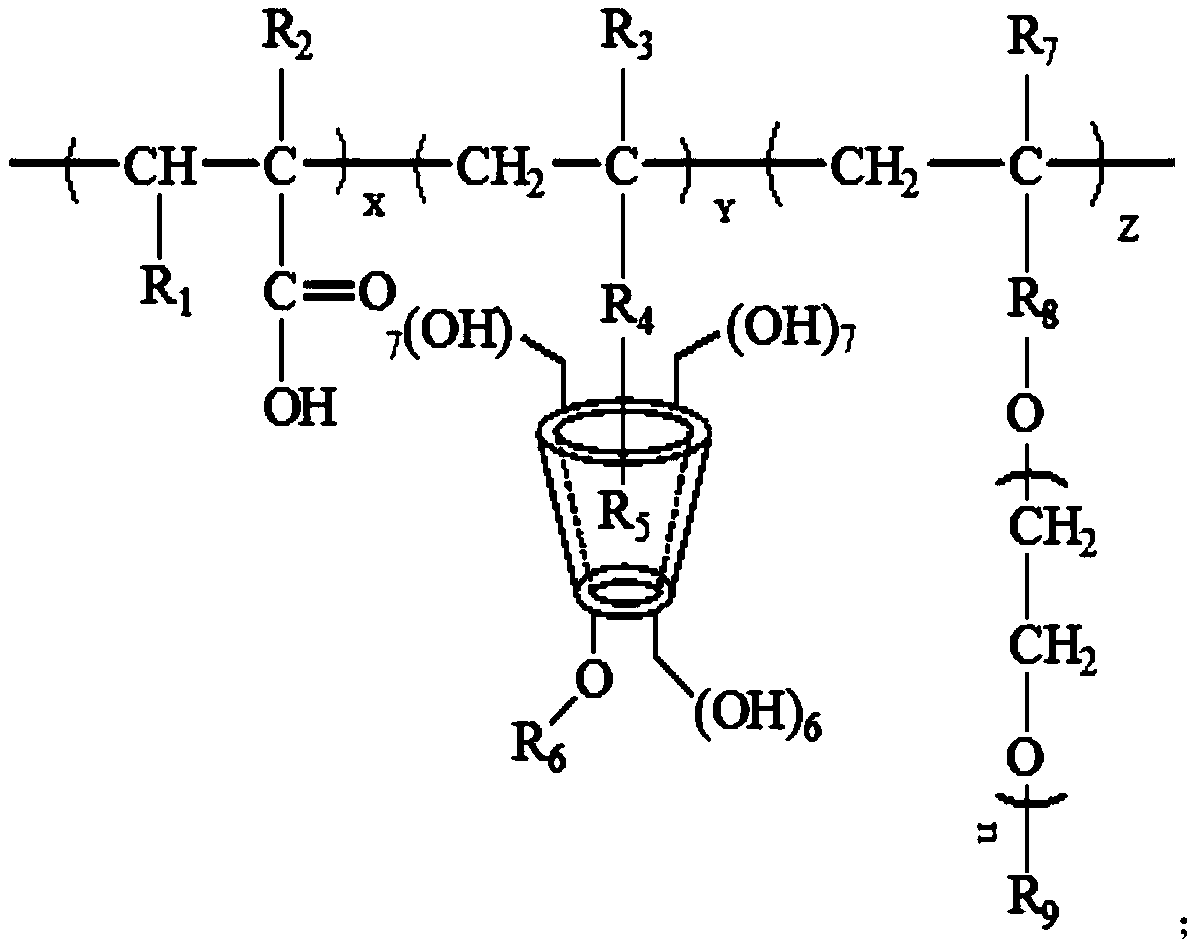

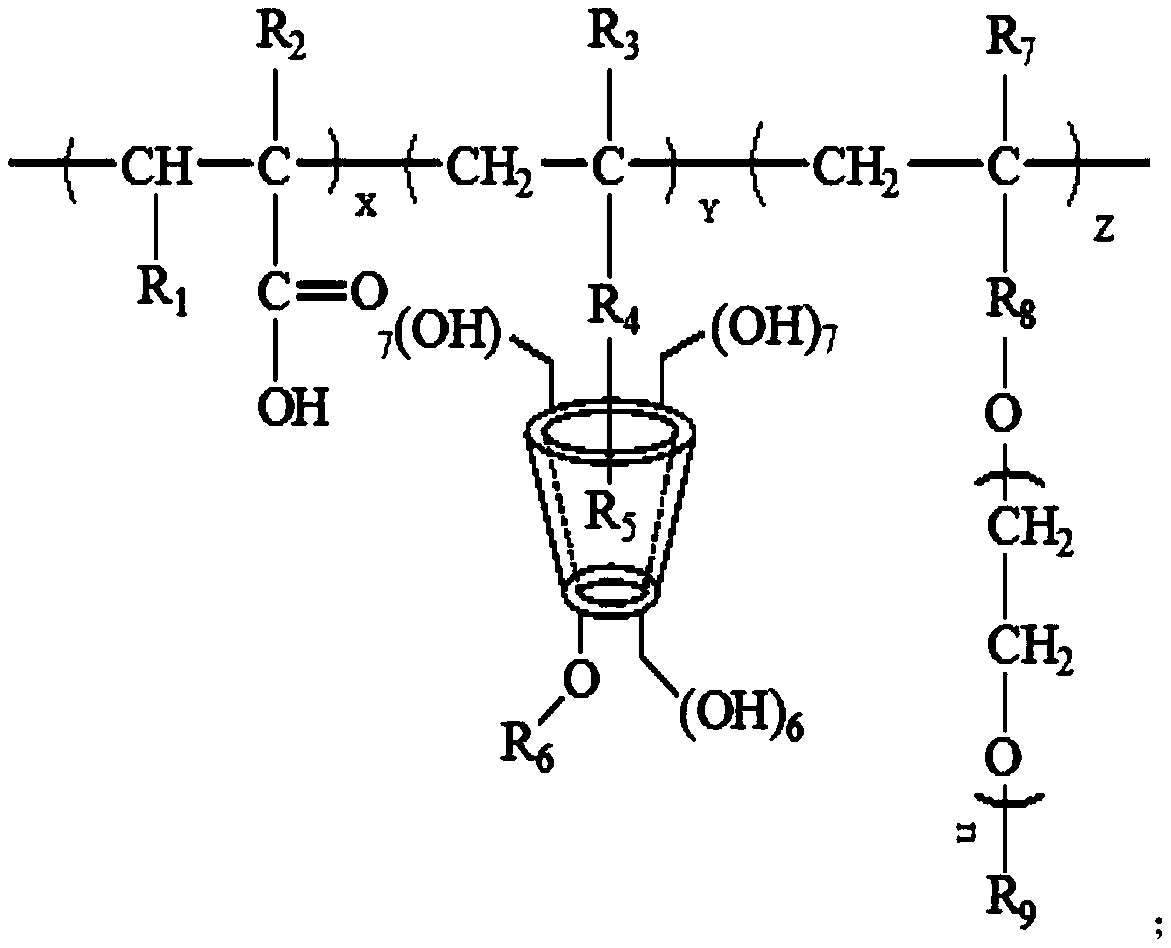

A modified cyclodextrin self-assembled polycarboxylate water reducer and its preparation method

A cyclodextrin and polycarboxylic acid technology, which is applied in the field of concrete, can solve the problems of difficult to meet safety production, energy conservation and environmental protection, difficult to guarantee product quality, complicated preparation methods, etc., and achieves improved slump retention capability, low cost, and improved adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

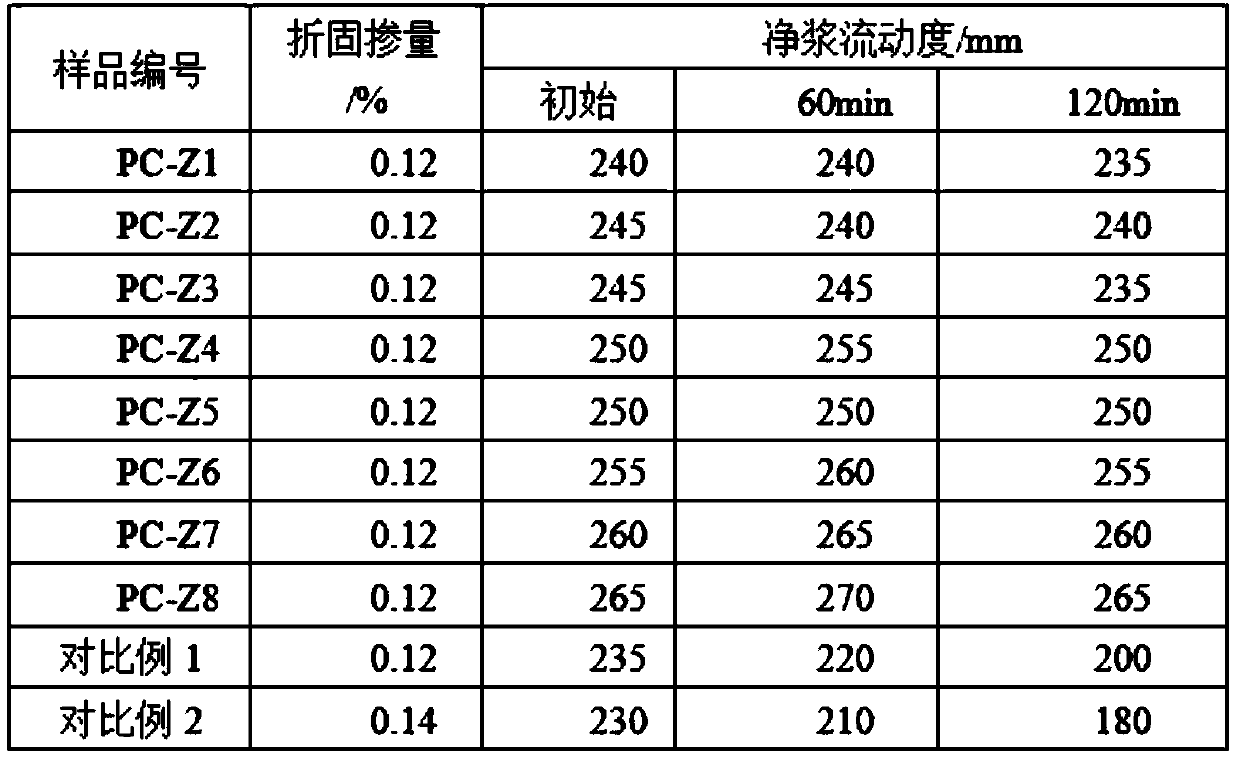

Embodiment 1

[0028] Dissolve 0.15 mol of hydroxypropyl-β-cyclodextrin in deionized water, add 0.15 mol of n-butyl acrylate, stir at room temperature for 1.0 h, add 1.0 mol of methallyl polyoxyethylene ether with a molecular weight of 2000 , heat up to 40°C, add 0.055mol hydrogen peroxide, add dropwise an aqueous solution containing 3.7mol acrylic acid, a mixed aqueous solution containing 0.016mol ascorbic acid and 0.056mol mercaptoacetic acid, the dropping time is 2h and 2.5h respectively, and keep warm for 1.0 h, then lower the temperature to 30°C, add liquid caustic soda and water with a mass fraction of 30%, adjust the pH value to 6-8, and obtain a product that is a modified cyclodextrin self-assembled polycarboxylate water reducer with a mass fraction of 40% PC-Z1.

Embodiment 2

[0030] Dissolve 0.15 mol of hydroxyethyl-β-cyclodextrin in deionized water, add 0.15 mol of n-propyl acrylate, stir at room temperature for 1.0 h, add 1.0 mol of polyethylene glycol monomethyl ether acrylate with a molecular weight of 2000, Raise the temperature to 60°C, add 0.069mol of hydrogen peroxide, add dropwise the aqueous solution containing 2.5mol acrylic acid and 1.2mol methacrylic acid, the mixed aqueous solution containing 0.015mol saffron and 0.07mol mercaptopropionic acid, and the dropping time is 2.5h and 3.0h, keep warm for 1.0h after the dropwise addition, then cool down to 50°C, add 30% mass fraction of liquid alkali and water, adjust the pH value to 6-8, and obtain the product which is 40% mass fraction of modified cyclodextrin Self-assembled polycarboxylate superplasticizer PC-Z2.

Embodiment 3

[0032]Dissolve 0.15 mol of hydroxyethyl-β-cyclodextrin in deionized water, add 0.15 mol of n-propyl methacrylate, stir at room temperature for 1.0 h, add 1.0 mol of polyethylene glycol monomethacrylate with a molecular weight of 2000 For methyl ether ester, heat up to 65°C, add 0.08mol hydrogen peroxide, add dropwise the aqueous solution containing 3.7mol methacrylic acid, the mixed aqueous solution containing 0.015mol sodium hypophosphite and 0.085mol mercaptoethanol, and the dropping time is 3.0h and 3.0h, keep warm for 1.5h after the dropwise addition, then lower the temperature to 50°C, add liquid caustic soda and water with a mass fraction of 30%, adjust the pH value to 6-8, and obtain a product that is a modified cyclodextrin with a mass fraction of 40% Self-assembled polycarboxylate superplasticizer PC-Z3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com