Antirust high-lubricity cutting fluid and preparation process thereof

A preparation process and lubricity technology, applied in the field of rust-proof and high-lubricity cutting fluid and its preparation process, can solve the problems of insufficient anti-rust performance, lubricating friction performance and anti-oxidation performance of the cutting fluid, and achieve good film formation. Post-stable performance, good film-forming properties, and the effect of film-forming energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

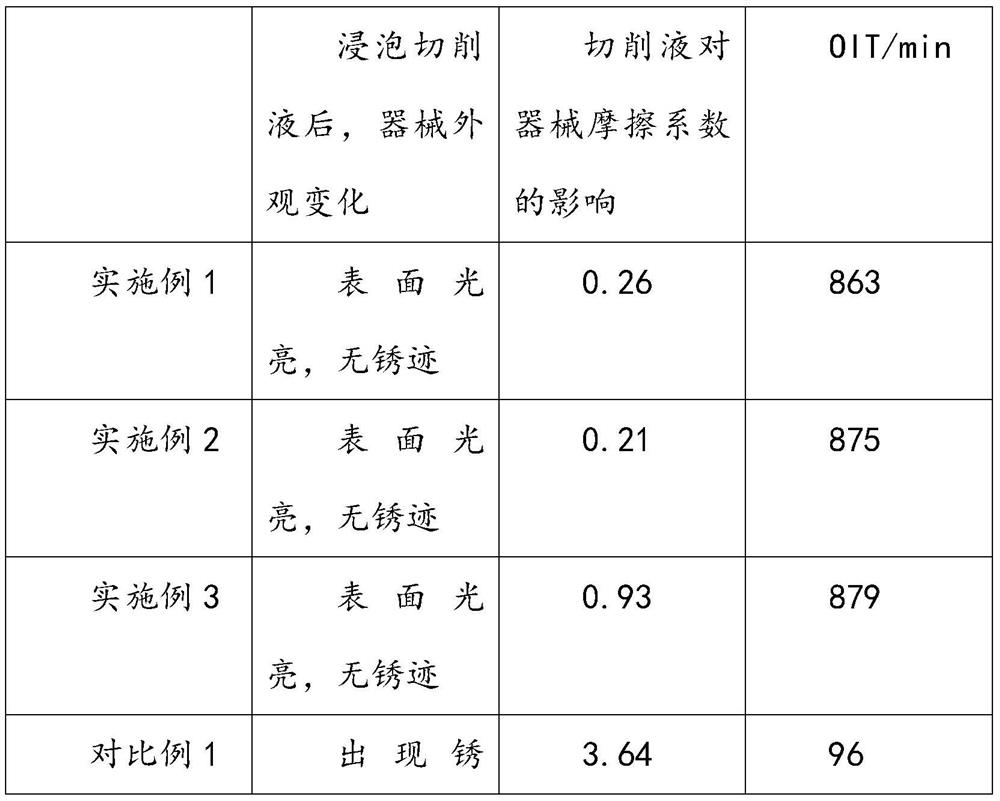

Examples

Embodiment 1

[0038] A kind of antirust high lubricating cutting fluid, is made up of following raw materials in parts by weight: 30 parts of synthetic base oil, 40 parts of deionized water, 15 parts of glycerin, 8 parts of modified rust remover, 18 parts of graphene dispersion liquid, antiwear 12 parts of extreme pressure agent and 8 parts of antioxidant;

[0039] The preparation process of the rust-proof high-lubricity cutting fluid comprises the following steps:

[0040] The first step: prepare modified rust remover, graphene dispersion, anti-wear extreme pressure agent and antioxidant, standby;

[0041] Step 2: Stir the synthetic base oil, deionized water and glycerin at a temperature of 50°C for 20 minutes to obtain liquid A; control the mass ratio of the synthetic base oil, deionized water and glycerin to 30:40:15;

[0042] Step 3: Add modified rust remover, graphene dispersion, anti-wear extreme pressure agent and modified antioxidant to liquid A in sequence, and shear at a high spe...

Embodiment 2

[0060] A kind of antirust high lubricating cutting fluid, is made up of following raw materials in parts by weight: 35 parts of synthetic base oils, 45 parts of deionized water, 18 parts of glycerin, 10 parts of modified rust removers, 19 parts of graphene dispersions, anti-wear 13 parts of extreme pressure agent and 10 parts of antioxidant;

[0061] The preparation process of the rust-proof high-lubricity cutting fluid comprises the following steps:

[0062] The first step: prepare modified rust remover, graphene dispersion, anti-wear extreme pressure agent and antioxidant, standby;

[0063] Step 2: Stir the synthetic base oil, deionized water and glycerin at a temperature of 55°C for 25 minutes to obtain liquid A; control the mass ratio of the synthetic base oil, deionized water and glycerin to 35:45:18;

[0064] Step 3: Add modified rust remover, graphene dispersion, anti-wear extreme pressure agent and modified antioxidant to liquid A in sequence, and shear at a high spee...

Embodiment 3

[0082] A kind of antirust high lubricating cutting fluid, is made up of following raw materials in parts by weight: 40 parts of synthetic base oil, 50 parts of deionized water, 20 parts of glycerin, 12 parts of modified rust remover, 20 parts of graphene dispersion liquid, anti-wear 15 parts of extreme pressure agent and 12 parts of antioxidant;

[0083]The preparation process of the rust-proof high-lubricity cutting fluid comprises the following steps:

[0084] The first step: prepare modified rust remover, graphene dispersion, anti-wear extreme pressure agent and antioxidant, standby;

[0085] Step 2: Stir the synthetic base oil, deionized water and glycerin at a temperature of 60°C for 30 minutes to obtain liquid A; control the mass ratio of the synthetic base oil, deionized water and glycerin to 40:50:20;

[0086] Step 3: Add modified rust remover, graphene dispersion, anti-wear extreme pressure agent and modified antioxidant to liquid A in sequence, and shear at a high s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com