Method for recovering silver, indium and cadmium from silver-indium-cadmium alloy waste

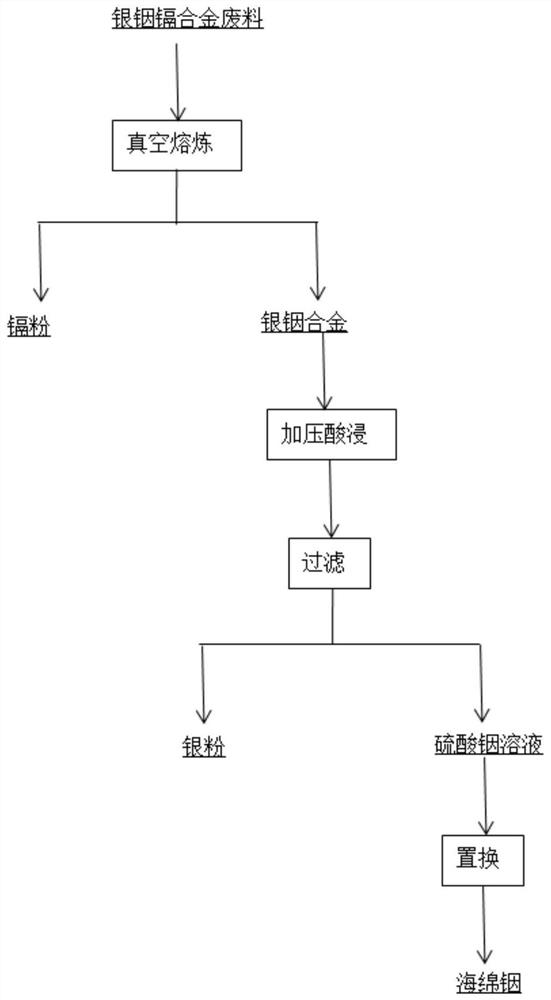

A technology of cadmium alloy and indium alloy, which is applied in the field of scrap recycling, can solve the problems of difficulty in recycling silver indium cadmium alloy scrap, and achieve the effects of being environmentally friendly, having a high recovery rate and a short recovery process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0032] This embodiment provides a method for reclaiming silver, indium, and cadmium from silver-indium-cadmium alloy waste, comprising the following steps:

[0033] Step 1. Put the silver-indium-cadmium alloy waste in a vacuum reaction melting furnace, vacuumize it, and melt it at 1050°C for 2 hours to generate cadmium vapor and silver-indium alloy melt. The cadmium vapor enters the gas phase collection device to obtain cadmium powder, and the silver Indium alloy melt is cast in the mould, obtains the silver-indium alloy that is solid; The described silver-indium-cadmium alloy scrap is placed in the crucible of vacuum reaction melting furnace, and the material of described crucible is graphite, and the power of described vacuum reaction melting furnace is 200kw; the mass content of silver in the silver-indium-cadmium alloy waste is 82%, the mass content of indium is 14%, and the mass content of cadmium is 4%; the particle diameter of the cadmium powder is 5 μm~8 μm; The mass p...

Embodiment 3

[0038] This embodiment provides a method for reclaiming silver, indium, and cadmium from silver-indium-cadmium alloy waste, comprising the following steps:

[0039] Step 1. Put the silver-indium-cadmium alloy waste in a vacuum reaction melting furnace, vacuumize it, and melt it at 1050°C for 2 hours to generate cadmium vapor and silver-indium alloy melt. The cadmium vapor enters the gas phase collection device to obtain cadmium powder, and the silver Indium alloy melt is cast in the mould, obtains the silver-indium alloy that is solid; The described silver-indium-cadmium alloy scrap is placed in the crucible of vacuum reaction melting furnace, and the material of described crucible is graphite, and the power of described vacuum reaction melting furnace is 200kw; the mass content of silver in the silver-indium-cadmium alloy waste is 85%, the mass content of indium is 10%, and the mass content of cadmium is 5%; the particle diameter of the cadmium powder is 5 μm~8 μm; The mass p...

Embodiment 4

[0044] This embodiment provides a method for reclaiming silver, indium, and cadmium from silver-indium-cadmium alloy waste, comprising the following steps:

[0045] Step 1. Put the silver-indium-cadmium alloy waste in a vacuum reaction melting furnace, vacuumize it, and melt it at 1150° C. for 2.5 hours to generate cadmium vapor and silver-indium alloy melt. The cadmium vapor enters the gas phase collection device to obtain cadmium powder. The silver-indium alloy melt is cast in a mold to obtain a solid silver-indium alloy; the silver-indium-cadmium alloy waste is placed in a crucible of a vacuum reaction melting furnace, the material of the crucible is graphite, and the power of the vacuum reaction melting furnace is is 200kw; the mass content of silver in the silver-indium-cadmium alloy waste is 85%, the mass content of indium is 10%, and the mass content of cadmium is 5%; the particle diameter of the cadmium powder is 8 μm~9 μm; in the present embodiment The mass purity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com