Method for extracting lithium from waste lithium ion battery and application thereof

A lithium-ion battery and battery technology, applied in the field of lithium extraction, can solve the problems of high impurities in lithium-rich solution, high work intensity, and many control points, and achieve the effects of no secondary pollution, short recovery process, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

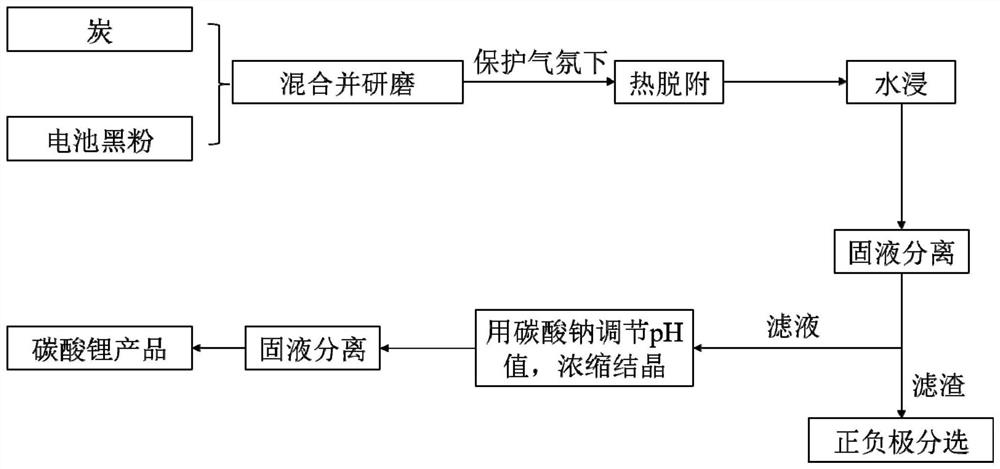

Method used

Image

Examples

Embodiment 1

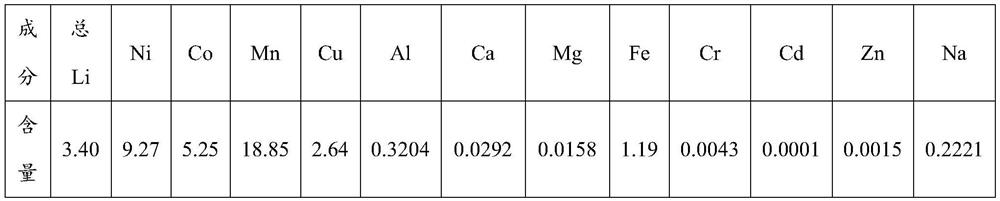

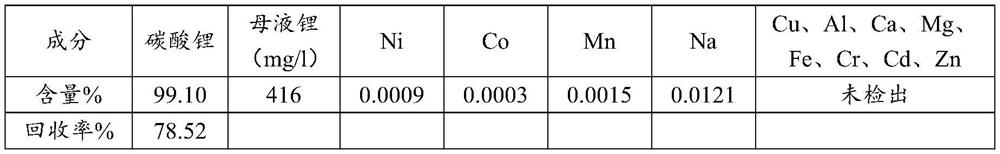

[0043]With the reclaimed ternary lithium battery as raw material (see Table 1 for the composition), the total lithium in the battery is calculated at 3.40%, and 400 mesh activated carbon powder is used as the extractant, and 20.015g of black powder and activated carbon powder are weighed (the amount of activated carbon powder is calculated according to the amount of black powder). Lithium ions in the powder: carbon = 1:0.5 molar ratio) were mixed and ground for 60 minutes, and the ground mixture was desorbed in a tube furnace at 700°C for 180 minutes under a nitrogen protection atmosphere, and then heated to the cooled heat Add 300mL deionized water to the deionized product, stir at 500rpm normal temperature on a magnetic stirrer for 3 hours, after the dissolved matter in the material is fully dissolved, filter to obtain the lithium-containing aqueous solution, adjust the concentration of the lithium-containing aqueous solution with sodium carbonate solid (analytical pure) The ...

Embodiment 2

[0048] With the reclaimed ternary lithium battery as raw material (see Table 1 for the composition), the total lithium in the battery is calculated as 3.40%, and 400 mesh activated carbon powder is used as the extractant, and 20.021g of black powder and activated carbon powder are weighed (the amount of activated carbon powder is calculated according to the amount of black powder). Lithium ions in the powder: carbon = 1:1 molar ratio) were mixed and ground for 60 minutes, and the ground mixture was desorbed in a tube furnace at 700°C for 180 minutes under a nitrogen protective atmosphere, and then transferred to the cooled heat Add 300mL deionized water to the deionized product, stir at 500rpm normal temperature on a magnetic stirrer for 3 hours, after the dissolved matter in the material is fully dissolved, filter to obtain the lithium-containing aqueous solution, adjust the concentration of the lithium-containing aqueous solution with sodium carbonate solid (analytical pure) ...

Embodiment 3

[0053] With the reclaimed ternary lithium battery as raw material (see Table 1 for the composition), the total lithium in the battery is calculated at 3.40%, and 400 mesh activated carbon powder is used as the extractant, and 20.024g of black powder and activated carbon powder are weighed (the amount of activated carbon powder is calculated according to the amount of black powder). Lithium ions in the powder: carbon = 1:1.5 molar ratio) were mixed and ground for 60 minutes, and the ground mixture was desorbed in a tube furnace at 700°C for 180 minutes under a nitrogen protective atmosphere, and then transferred to the cooled heat Add 300mL deionized water to the deionized product, stir at 500rpm normal temperature on a magnetic stirrer for 3 hours, after the dissolved matter in the material is fully dissolved, filter to obtain the lithium-containing aqueous solution, adjust the concentration of the lithium-containing aqueous solution with sodium carbonate solid (analytical pure)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com