Welding of can bodies

A technology of tank body and welding roller, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as lack of skills, lack of clear understanding of welding process, and decreased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

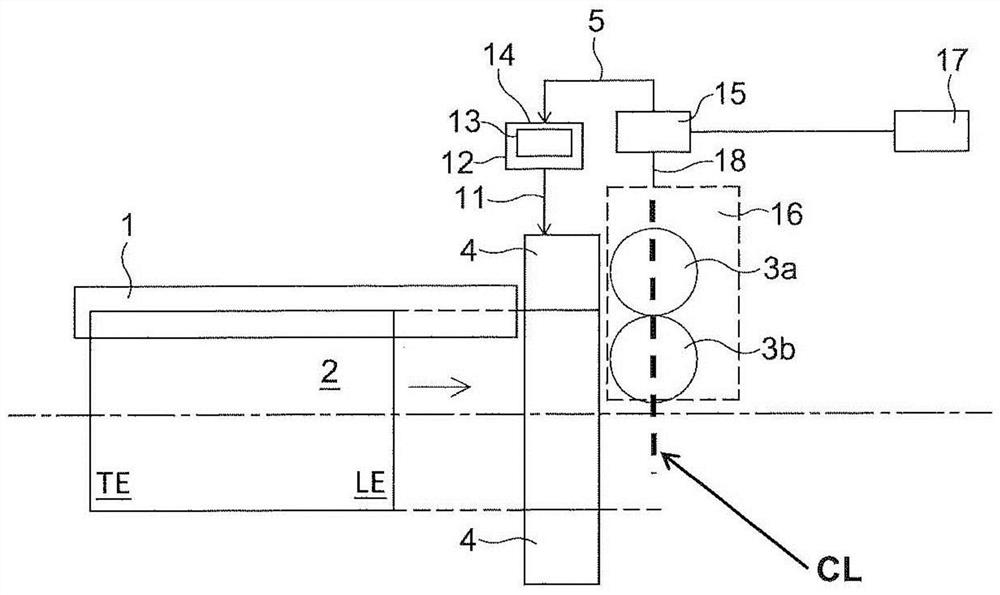

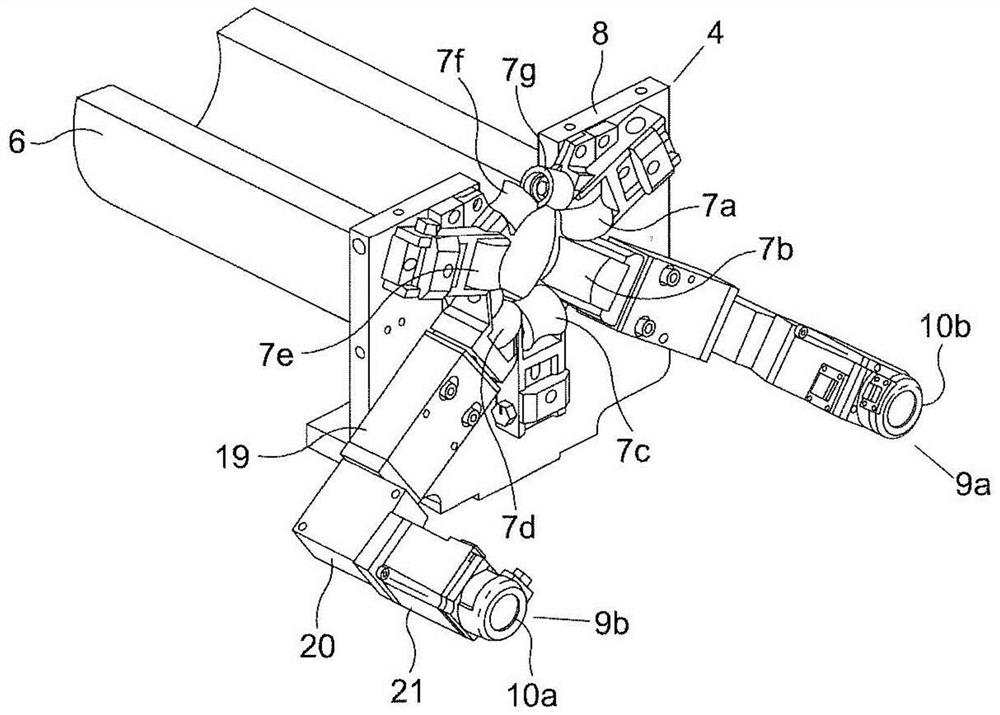

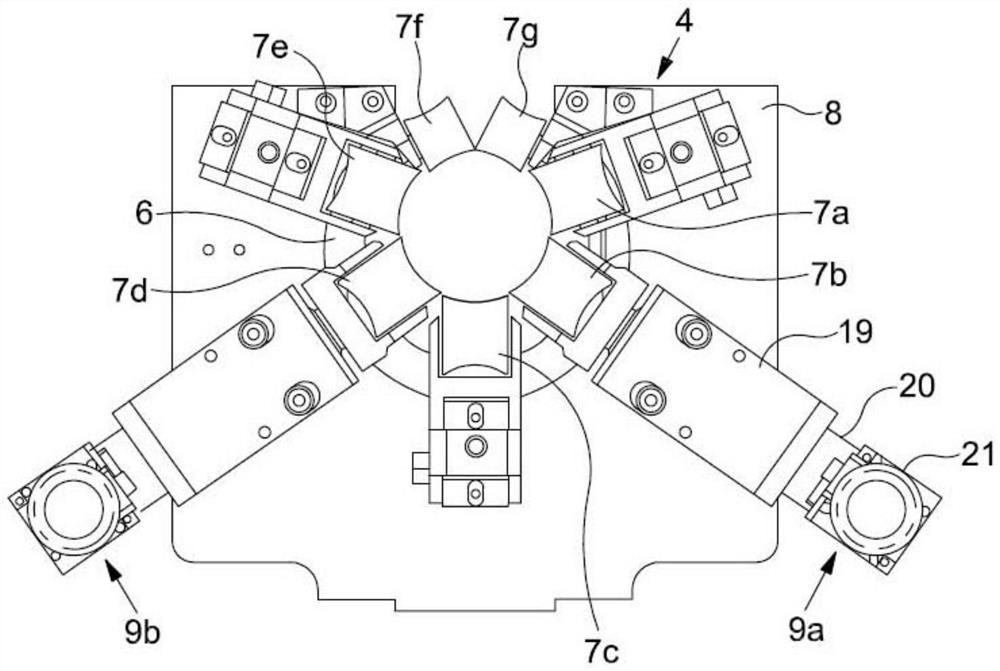

[0048] Embodiments of the present invention aim to provide closed-loop adjustment of the calibration unit of the welding station in order to automatically maintain a satisfactory weld thickness and / or weld quality for cylindrical tanks. figure 1 A welding station implementing such a closed-loop control is schematically shown. The station comprises a Z-shaped bar 1 along which a rolled metal cylinder 2 is conveyed towards a pair of opposing welding rolls 3a, 3b. As noted above, the function of the Z-bar is to bring the opposing edges of the cylinder into a substantially correct overlapping configuration as the cylinder moves away from the end of the Z-bar. A calibration unit 4 is located between the end of the Z-bar and the welding roller. The function of the calibration unit 4 is to control the cylinder overlap by making small adjustments to the circumference of the cylinder 2 . Various components of the welding station have been omitted from the drawings for the sake of bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com