Tandospirone pharmaceutical composition as well as preparation method and application thereof

A technology of tandospirone and its composition, which is applied in the field of tandospirone pharmaceutical composition and its preparation and application, can solve the problems of large blood drug concentration fluctuations, poor drug compliance, and large drug side effects, and achieve blood drug concentration Small fluctuations, few side effects, and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-20

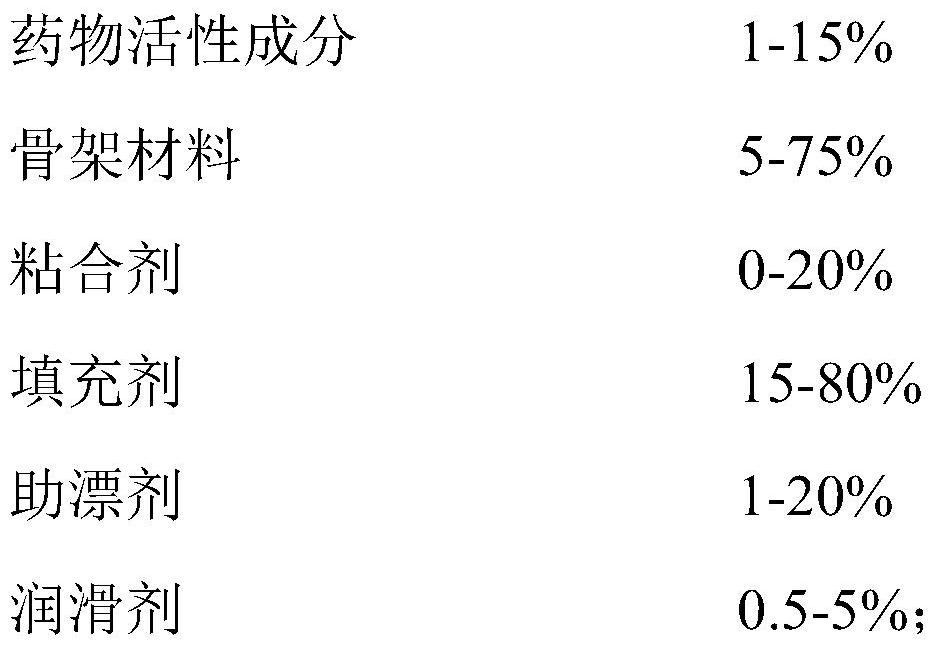

[0070] The tandospirone pharmaceutical composition is prepared according to the components and proportions shown in Tables 1-3.

[0071] Table 1. Tandospirone Pharmaceutical Compositions—Examples 1-8

[0072]

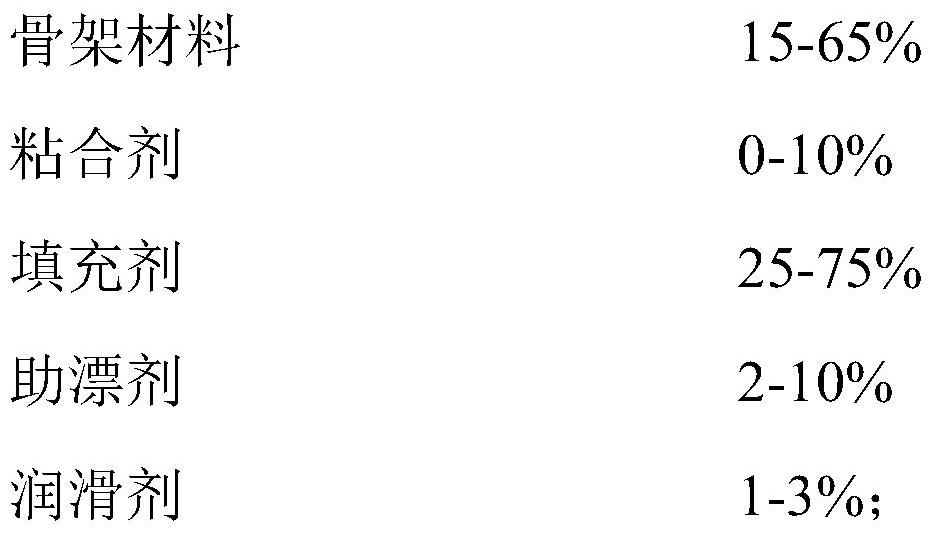

[0073] Table 2. Tandospirone Pharmaceutical Compositions—Examples 9-14

[0074]

[0075] Table 3. Tandospirone Pharmaceutical Compositions—Examples 15-20

[0076]

[0077]

Embodiment 1-7

[0078] For embodiment 1-7, 9-12 and 15-18, its preparation process is as follows:

[0079] a. Pass magnesium stearate through a 60-mesh sieve, and each component except magnesium stearate pass through a 20-mesh sieve respectively, take tandospirone citrate, skeleton material, binder and filler, and mix for 15 minutes ;

[0080] b. Add bleaching aid and mix for 10 minutes; then add magnesium stearate and mix for 3 minutes to obtain mixed powder;

[0081] c. Using a punch of 16.4 mm×7.9 mm to directly compress the mixed powder prepared in step b to obtain a tablet.

Embodiment 8

[0082] For embodiment 8, 13-14 and 19-20, its preparation process is as follows:

[0083] a. Pass tandospirone citrate, skeleton material, binder and filler through a 20-mesh sieve respectively, and mix for 10 minutes; add water to prepare a soft material, dry the wet granules at 50°C and 35cfm for 15 minutes, and dry The granules are passed through a 20-mesh sieve to obtain dry granules;

[0084] B, the bleaching aid is passed through a 20-mesh sieve, mixed with the dry granules prepared in step a for 5 minutes; then adding magnesium stearate (passed through a 60-mesh sieve) and mixed for 3 minutes to obtain mixed granules;

[0085] c. Using a punch of 16.4 mm×7.9 mm to compress the mixed granules prepared in step b to obtain a tablet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com