Metal porous strip and powder composite rolling and sintering integrated process and device

A metal porous, metal powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of reducing production efficiency, increasing energy consumption in stirring and degreasing processes, etc., to improve production efficiency, save process and equipment investment, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

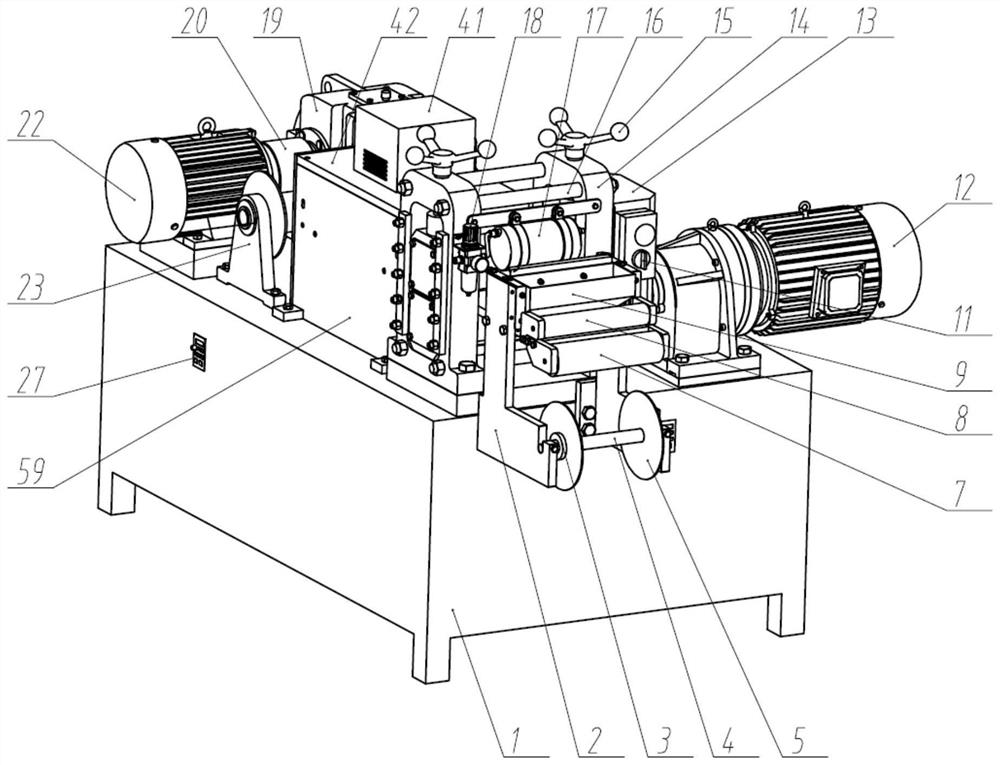

[0042] see Figure 1 to Figure 6 As shown, the metal porous strip and powder composite rolling and sintering integrated device provided in this embodiment include a frame 1, a powder laying mechanism, a rolling mechanism, a sintering mechanism and a material winding mechanism;

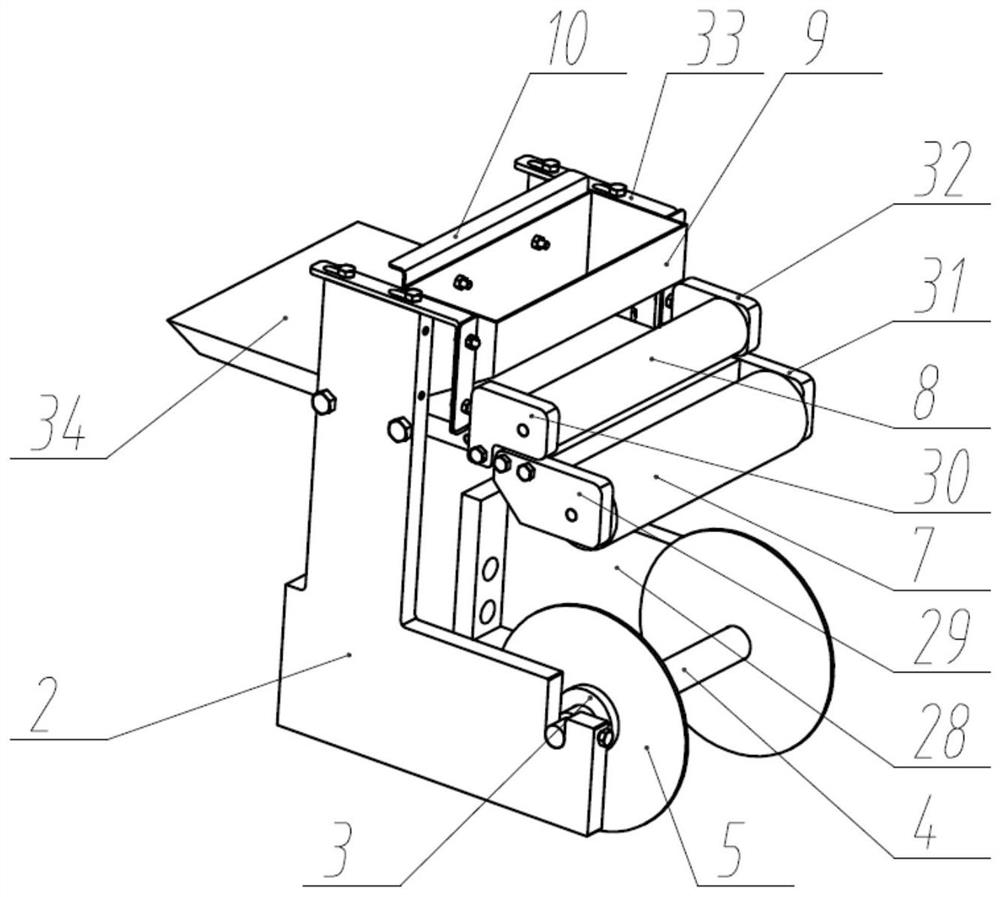

[0043] Wherein, the powder laying mechanism is arranged on the top of the frame 1, and the powder laying mechanism includes a first L-shaped mounting plate 2, an adjustment ring 3, a coil shaft 4, an annular baffle 5, a transfer shaft 7, and a pressing roller 8. Hopper 9, baffle plate 10, second L-shaped mounting plate 28, first transfer shaft installation block 29, first pressure roller installation block 30, second transfer shaft installation block 31, second pressure roller installation block 32. L-shaped adjustment bracket 33 and material paving plate 34; the first L-shaped mounting plate 2 and the second L-shaped mounting plate 28 are installed on the top of the frame 1, and the two ends of the co...

Embodiment 2

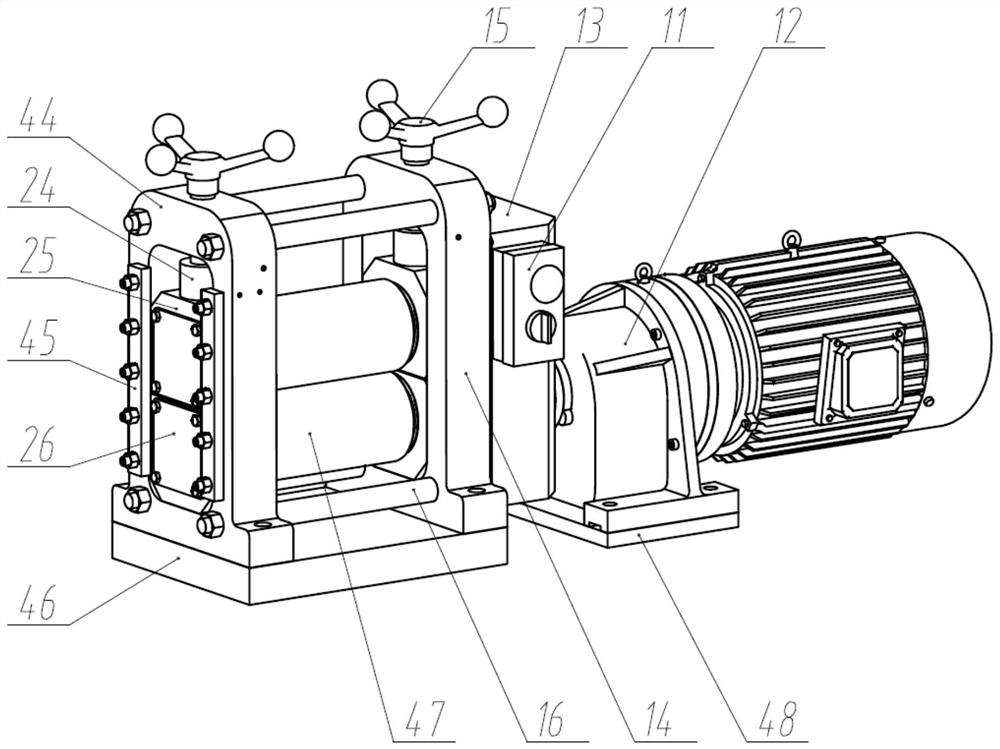

[0049] The difference from Example 1 is that the rolling raw materials of this embodiment are metal powder and wire mesh plate, and the process of making metal powder and wire mesh plate into metal porous material is as follows: first, place the wire mesh plate on Below the hopper 9, lay the metal powder thickness to adjust the baffle plate 10 to a suitable height, add metal powder into the hopper 9, control the speed of the gear reduction motor 12 by adjusting the main frequency converter 6, turn on the switch 11, and start the rolling device. The metal mesh plate is rolled by the roll 47 to drive the metal powder to be continuously pulled out from the hopper 9, and the metal powder particles are evenly laid on the surface of the wire mesh plate. After the wire mesh plate and the metal powder composite plate enter the rolling area, they are rolled under the action of two rolls 47 . This embodiment can realize the rolling of metal powder particles of any size and metal mesh pl...

Embodiment 3

[0051] The difference from Embodiment 1 is that the integrated device of porous metal strip and powder composite rolling and sintering in this embodiment also includes a gas atomization spraying mechanism. see Figure 7 As shown, the aerosolized spraying mechanism includes a water tank 17, a pressure regulating valve 18, a quick-plug connector 35, an air pipe 36, a clamp 37, a nozzle 38, a safety relief valve 39 and a lateral mounting plate 40; the lateral mounting The plate 40 is fixed on the first mounting frame 14 and the second mounting frame 44 of the rolling device, the water tank 17 is fixed below the horizontal mounting plate 40 through a clamp 37, and a safety relief valve 39 is installed on the right end of the water tank 17 , to prevent excessive pressure in the water tank, the nozzle 38 is installed below the water tank 17, and is facing the upper surface of the material spreading plate 34 of the powder laying mechanism, and the quick-plug connector is installed ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com