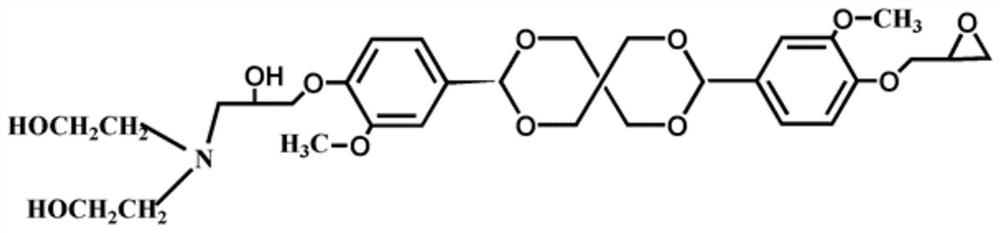

Waterborne epoxy resin emulsion as well as preparation method and application thereof

A water-based epoxy resin and epoxy resin technology, applied in textiles and papermaking, recycling technology, fiber treatment, etc., can solve problems such as unsatisfactory effect and inability to form a uniform and stable emulsion, and achieve stable thermodynamics and excellent performance of the system , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

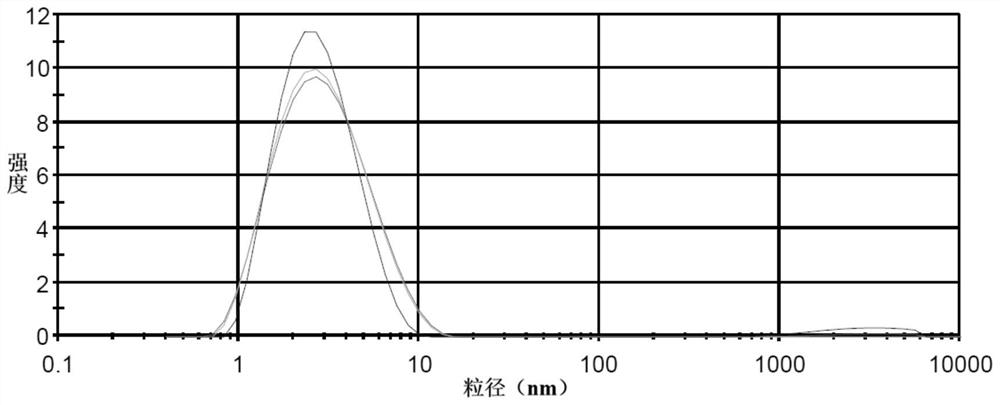

[0032] 1) Add 20mL of absolute ethanol and 12g of epoxy resin containing a helical ring acetal structure into a three-necked flask in turn, measure 2g of diethanolamine and drop it into the reaction system, raise the temperature to 80°C, and react for several hours. Become clarified, leave standstill to remove ethanol and promptly obtain the epoxy resin containing helical ring acetal structure modified by diethanolamine;

[0033] 2) Weigh 0.5g of the surfactant obtained in step 1), place 2.0g of E51 epoxy resin and measure 20g of absolute ethanol to be miscible at 50°C;

[0034] 3) Add 100 mL of deionized water to the solution in 2), and add 0.1 g of acetic acid for neutralization. After the neutralization reaction is complete, a water-based epoxy resin emulsion is obtained.

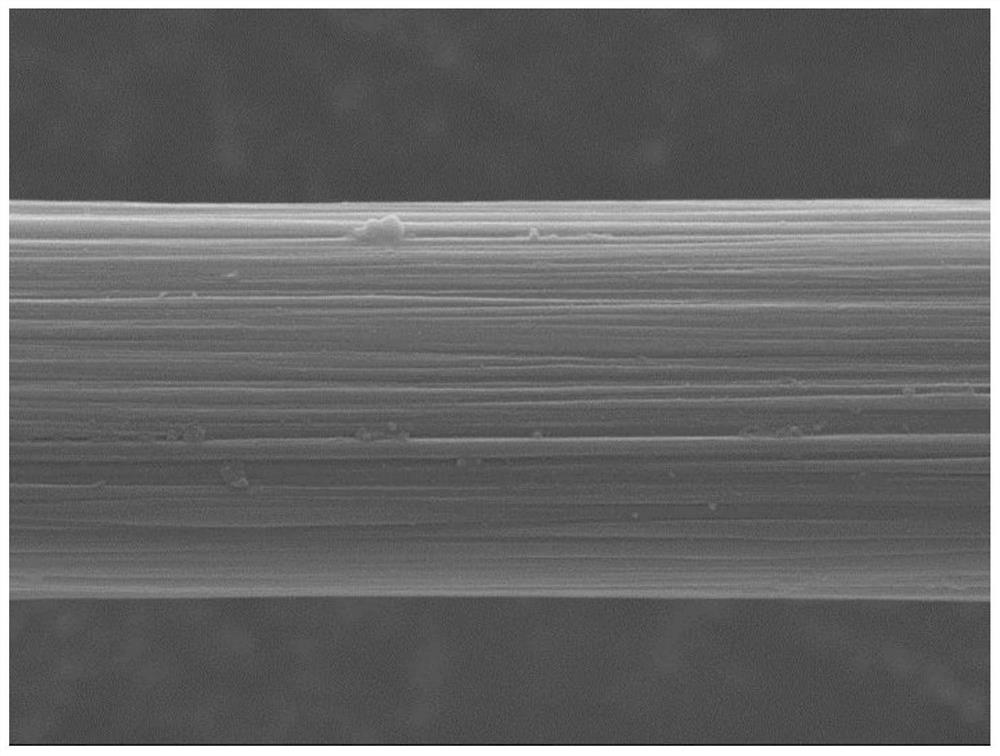

[0035] 4) Sizing agent preparation: the water-based epoxy resin emulsion is prepared as a sizing agent, and its solid content is 2%;

[0036] 5) Sizing drying: put the prepared sizing agent in the sizin...

Embodiment 2

[0038] The difference between the water-based epoxy resin emulsion in this embodiment and the water-based epoxy resin emulsion in Example 1 is that: 1) the epoxy resin used in is E51.

Embodiment 3

[0040] The difference between the water-based epoxy resin emulsion in this example and the water-based epoxy resin emulsion in Example 1 is that the amount of ethanol used is 12g.

[0041] The water-based epoxy resin emulsion system of this embodiment is unstable, and the precipitation increases with prolongation of standing time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com