A kind of preparation method of amino acid modified self-emulsifying waterborne epoxy resin

A water-based epoxy resin and epoxy resin technology, applied in the field of amino acids, can solve the problems of ecological environment damage and epoxy resin insoluble in water, etc., and achieve the effects of good emulsification performance, good water resistance and alkali resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

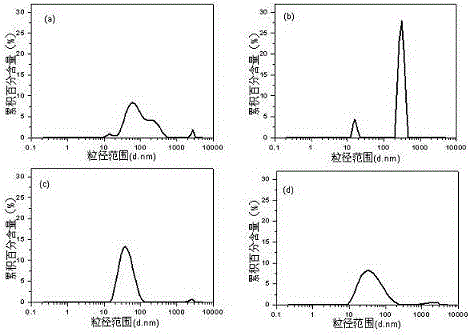

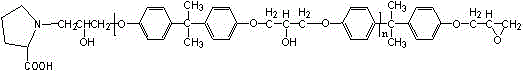

[0037] 1) Add 20ml of absolute ethanol and 23.5g of epoxy resin E-42 (epoxy value 0.42mol / 100g) into a 250ml three-neck flask in turn, then place the flask in an oil bath, heat it to 70°C, and turn it on Stirring device to mix anhydrous ethanol and epoxy resin evenly;

[0038] 2) Weigh 3.45g of L-proline and put it into the reaction system. After a few hours, after the reaction is complete, the mixed liquid of modified epoxy resin containing carboxyl groups can be obtained;

[0039] 3) Add 3.03g of triethylamine to the mixed liquid in step 2), and carry out neutralization reaction at 60°C;

[0040] 4) After the neutralization reaction is complete, slowly add deionized water dropwise under high-speed stirring to prepare a water-based epoxy resin emulsion with a solid content of 50%;

[0041] 5) Mix the synthesized water-based epoxy resin emulsion and water-based epoxy curing agent at a molar ratio of epoxy group to amine group of 1:1, stir evenly to obtain a water-based epoxy ...

Embodiment 2

[0051]1) Add 20ml of absolute ethanol and 22.5g of epoxy resin E-44 (epoxy value 0.44mol / 100g) into a 250ml three-neck flask in turn, then place the flask in an oil bath, heat to 70°C, and start stirring device to mix absolute ethanol and epoxy resin evenly;

[0052] 2) Weigh 3.45g of L-proline and put it into the reaction system. After a few hours, after the reaction is complete, the mixed liquid of modified epoxy resin containing carboxyl groups can be obtained;

[0053] 3) Add 3.03g of triethylamine to the mixed liquid in step 2), and carry out neutralization reaction at 60°C;

[0054] 4) After the neutralization reaction is complete, slowly add deionized water dropwise under high-speed stirring to prepare a water-based epoxy resin emulsion with a solid content of 50%;

[0055] 5) Mix the synthesized water-based epoxy resin emulsion and water-based epoxy curing agent at a molar ratio of epoxy group to amine group of 1:1, stir evenly to obtain a water-based epoxy varnish, a...

Embodiment 3

[0065] 1) Add 20ml of absolute ethanol and 19.5g of epoxy resin E-51 (epoxy value 0.51mol / 100g) into a 250ml three-neck flask in turn, then place the flask in an oil bath, heat to 70°C, and turn on Stirring device to mix anhydrous ethanol and epoxy resin evenly;

[0066] 2) Weigh 3.45g of L-proline and put it into the reaction system. After a few hours, after the reaction is complete, the mixed liquid of modified epoxy resin containing carboxyl groups can be obtained;

[0067] 3) Add 3.03g of triethylamine to the mixed liquid in step 2), and carry out neutralization reaction at 60°C;

[0068] 4) After the neutralization reaction is complete, slowly add deionized water dropwise under high-speed stirring to prepare a water-based epoxy resin emulsion with a solid content of 50%;

[0069] 5) Mix the synthesized water-based epoxy resin emulsion and water-based epoxy curing agent at a molar ratio of epoxy group to amine group of 1:1, stir evenly to obtain a water-based epoxy varnis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com