Preparation method of sei film on surface of lithium battery electrode material and film-containing electrode material

An electrode material, lithium battery technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of long production time, consumption of active lithium, capacity loss, etc., to save production time, widely applicable, The effect of easily controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of a kind of lithium battery electrode material surface SEI film that the present invention proposes comprises the following steps:

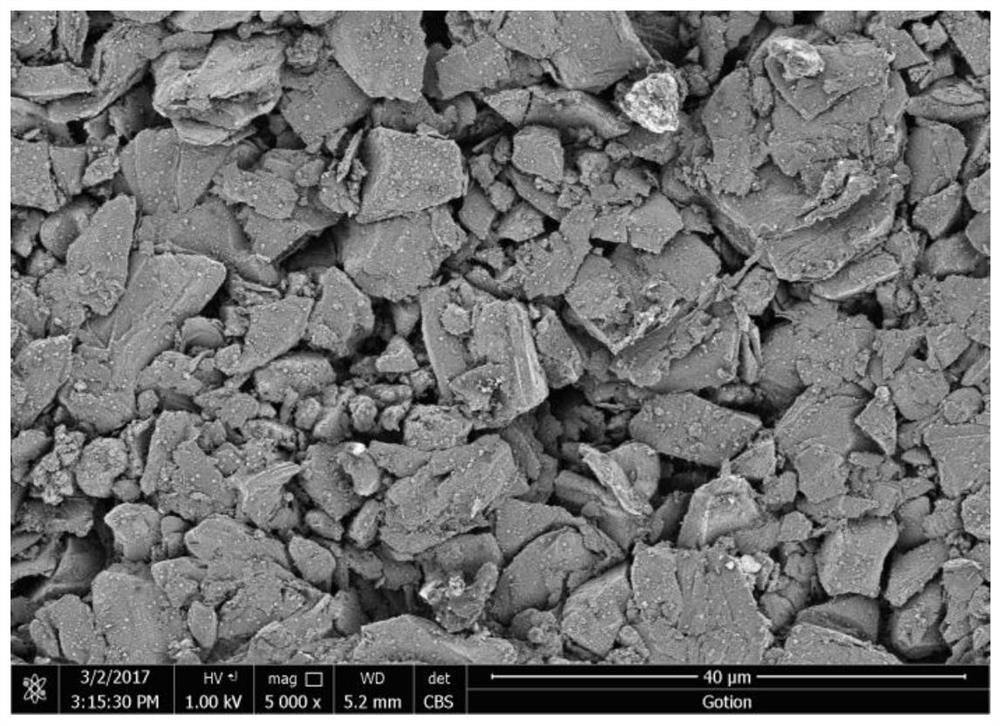

[0035] S1. Evenly disperse the graphite powder material into a 0.01mol / L tetrahydrofuran solution of lithium naphthalene, then stir so that the lithium naphthalene molecules are adsorbed on the surface of the graphite powder material, and obtain a modified graphite powder material through high-speed centrifugation;

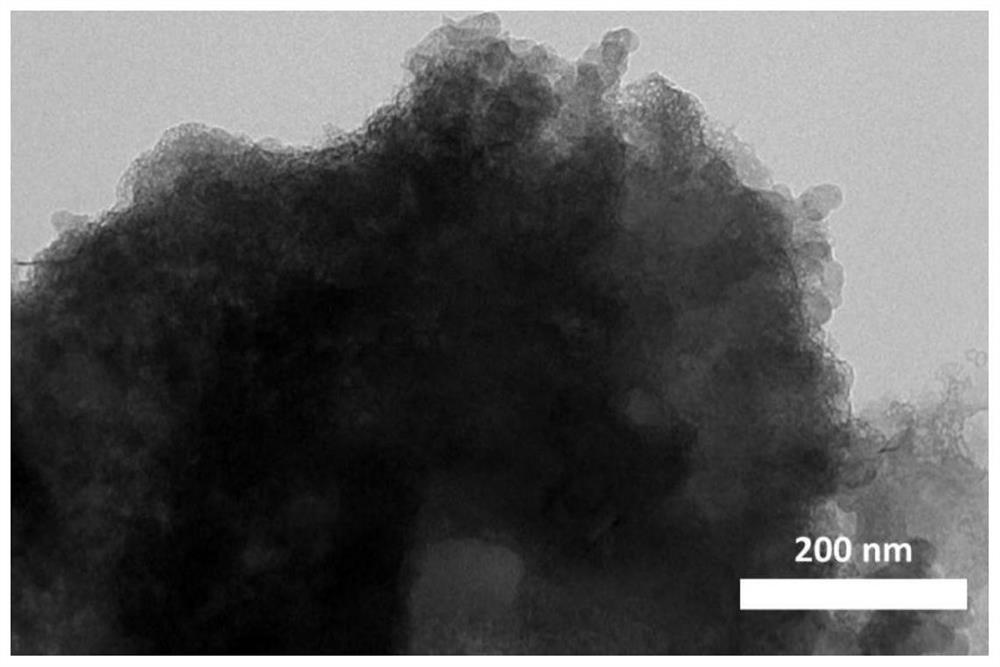

[0036] S2, uniformly dispersing the above-mentioned modified graphite powder material into fluoroethylene carbonate solvent, stirring to make lithium naphthalene and fluoroethylene carbonate fully react, and then high-speed centrifugation to obtain a graphite powder material coated with an SEI film on the surface;

[0037] S3. Repeat steps S1 and S2 three times for the graphite powder material coated with an SEI film on the surface, then rinse with dimethyl carbonate solvent to remove surface impurities,...

Embodiment 2

[0039] The preparation method of a kind of lithium battery electrode material surface SEI film that the present invention proposes comprises the following steps:

[0040] S1, the ternary LiNi 0.8 mn 0.1 co 0.1 o 2 The positive electrode material is uniformly dispersed in a 0.01mol / L lithium aluminum hydride ether solution, and stirred so that the lithium aluminum hydride molecules are adsorbed on the ternary LiNi 0.8 mn 0.1 co 0.1 o 2 On the surface of positive electrode material, high-speed centrifugation obtains modified LiNi 0.8 mn 0.1 co 0.1 o 2 Cathode material;

[0041] S2, the above-mentioned modified LiNi 0.8 mn 0.1 co 0.1 o 2 The positive electrode material is uniformly dispersed in the fluorovinylene carbonate solvent, stirred to fully react lithium aluminum hydride and fluorovinylene carbonate, and then centrifuged at a high speed to obtain LiNi coated with an SEI film on the surface 0.8 mn 0.1 co 0.1 o 2 Cathode material;

[0042] S3, LiNi coated w...

Embodiment 3

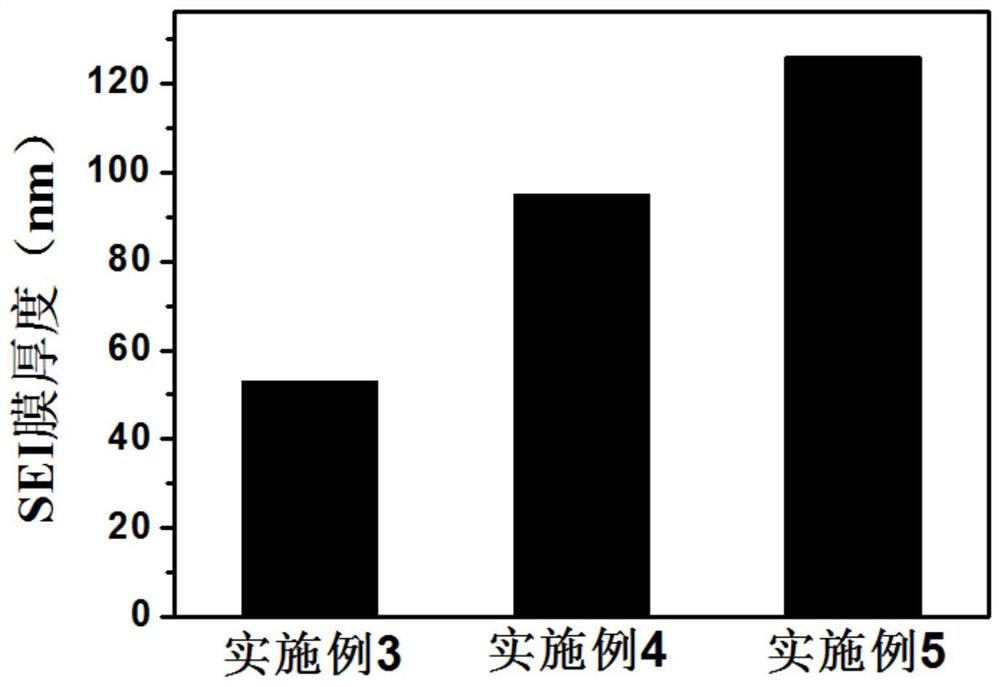

[0044] The preparation method of a kind of lithium battery electrode material surface SEI film that the present invention proposes comprises the following steps:

[0045] S1. Immerse the graphite powder material in a 0.01mol / L lithium borohydride ether solution, stir so that the lithium borohydride molecules are adsorbed on the surface of the graphite powder material, and obtain a modified graphite powder material through high-speed centrifugation;

[0046] S2. Evenly disperse the above-mentioned modified graphite powder material into diethyl fluorocarbonate solvent, stir to make lithium borohydride fully react with diethyl fluorocarbonate, and then centrifuge at a high speed to obtain graphite powder coated with an SEI film on the surface Material;

[0047] S3. Repeat steps S1 and S2 twice for the obtained graphite powder material coated with an SEI film on the surface, rinse with dimethyl carbonate solvent to remove surface impurities, and place it in a vacuum environment to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com