Silicon-containing low-chlorine epoxy resin and preparation method thereof

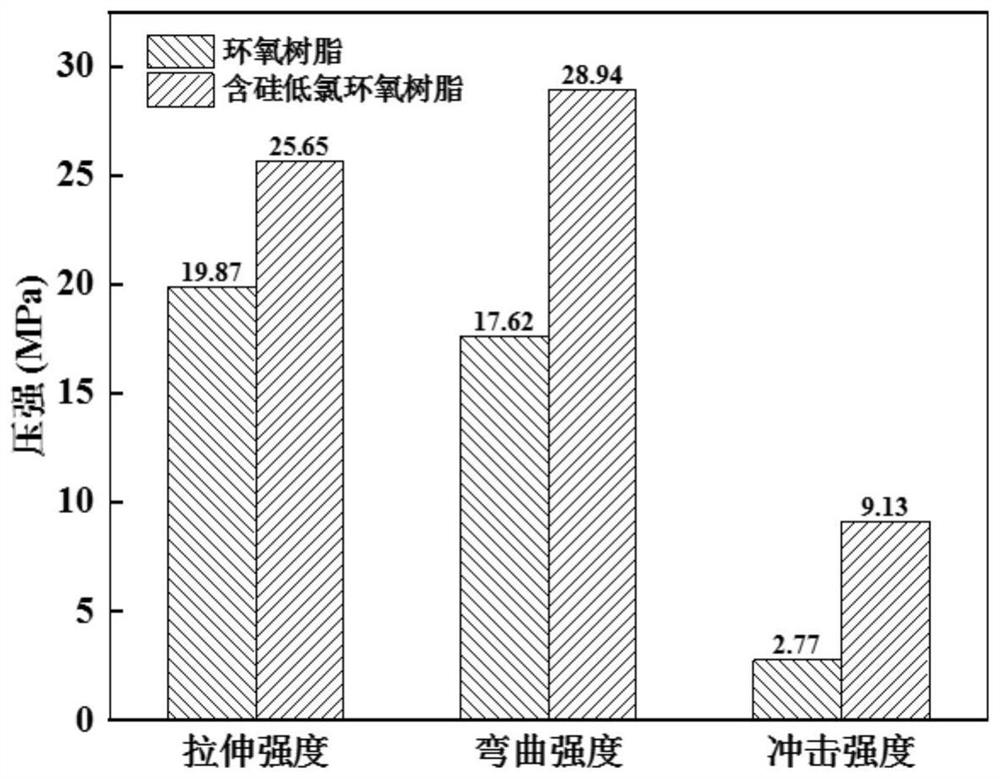

A technology of chlorine epoxy resin and epichlorohydrin, which is applied in the direction of silicon organic compounds, can solve the problem of insignificant chlorine removal effect, achieve clear reaction mechanism, increase strength, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

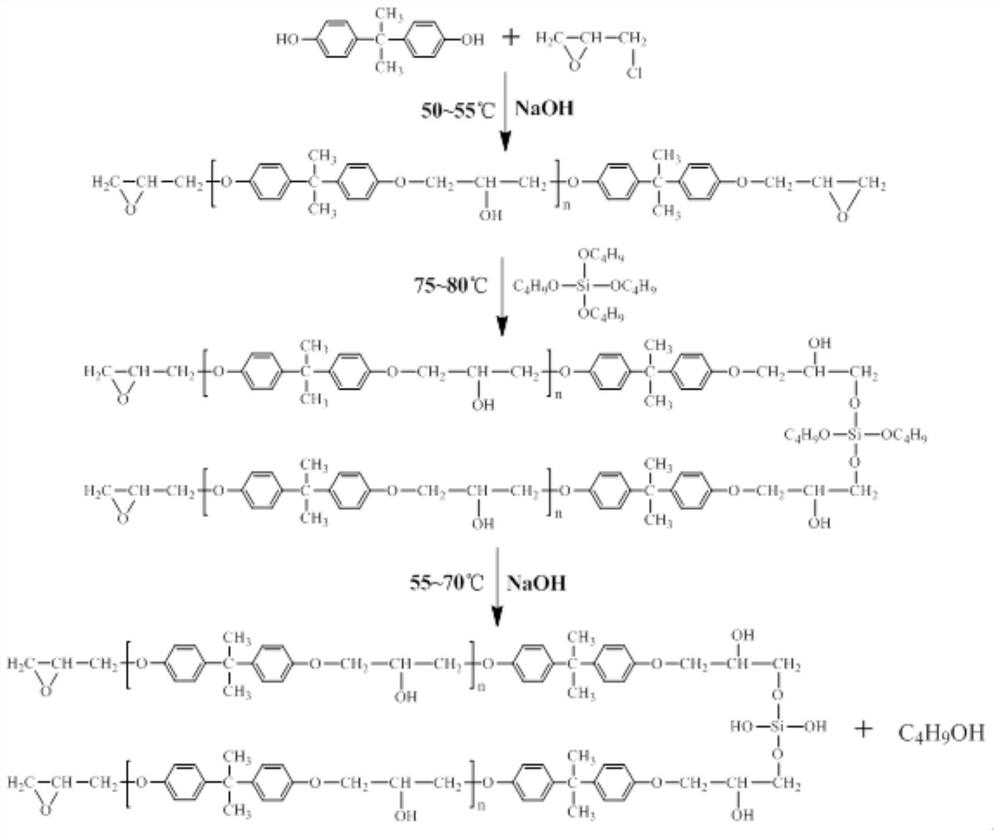

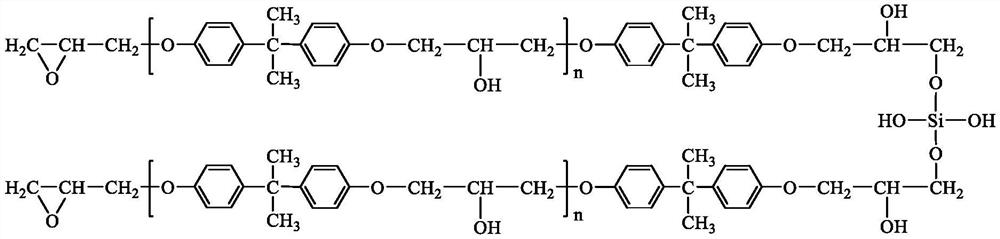

[0041] The preparation principle of the silicon-containing low-chlorine epoxy resin in the embodiment of the present application is as follows: when preparing the silicon-containing low-chlorine epoxy resin, firstly, the raw materials bisphenol A and epichlorohydrin undergo polycondensation reaction under the catalysis of NaOH to obtain epoxy resin. high polymer. Subsequently, the epoxy polymer reacts with butyl orthosilicate, and the butyl orthosilicate acts as a nucleophile to attack the epoxy group of the polymer to obtain a modified silicon-containing epoxy resin. On the basis of the traditional low-chlorine epoxy resin, a flexible silicon-containing segment is introduced, which improves the strength, temperature resistance, and moisture resistance of the epoxy resin after curing, improves its hydrophobicity, and reduces its water absorption. Therefore, The possibility of its hydrolysis can be reduced to a certain extent. On the basis of the traditional low-chlorine epoxy...

Embodiment 1

[0053] Add 1 mol of bisphenol A and 2.75 mol of epichlorohydrin into a three-necked flask equipped with a magnet, then raise the temperature to 65°C, and keep it warm for 30 minutes. After the reaction raw materials are completely dissolved, lower the temperature to 50°C, and add A 30% sodium hydroxide solution with a sodium hydroxide content of 1 mol was reacted for 4 hours to obtain the first intermediate product.

[0054] After the reaction is completed, the temperature is raised to 80° C., and the unreacted epichlorohydrin is recovered under reduced pressure under the condition of a vacuum degree >600 mmHg for 2 hours.

[0055] After recovery, the temperature was lowered to 75° C., and 0.5 mol of butyl orthosilicate was added into the three-necked flask, and the reaction was kept for 1 hour to obtain the second intermediate product. Add 60wt% benzene solvent to the second intermediate product, keep the temperature at 70° C. for 30 minutes to dissolve, and ensure that the s...

Embodiment 2

[0058] Add 1 mol of bisphenol A and 2.8 mol of epichlorohydrin into a three-necked flask equipped with a magnet, then raise the temperature to 70°C, and keep it warm for 40 minutes. After the reaction raw materials are completely dissolved, lower the temperature to 55°C, and add A 30% sodium hydroxide solution with a sodium hydroxide content of 1.5 mol was reacted for 5 hours.

[0059] After the reaction was completed, the temperature was raised to 75° C., and the unreacted epichlorohydrin was recovered under reduced pressure under the condition of vacuum degree >600 mmHg for 3 hours. After recovery, raise the temperature to 80°C, add 0.55mol of butyl orthosilicate to the three-necked flask, add 70wt% benzene solvent after 1.5h of heat preservation reaction, keep the temperature at 75°C for 40min to ensure that the contents of the three-necked flask are fully Soluble in benzene.

[0060] Cool down to 70°C, continue to slowly add dropwise a 30% sodium hydroxide solution with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com